Sulfur-tolerant non-noble metal catalyst and preparation method thereof

A non-precious metal and catalyst technology, which is applied in the field of non-precious metal catalyst preparation, can solve the problems of lowering, low melting point catalyst, loss of catalytic combustion treatment effect of organic waste gas, etc., and achieves the effect of low cost, simple method and high catalytic oxidation decomposition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

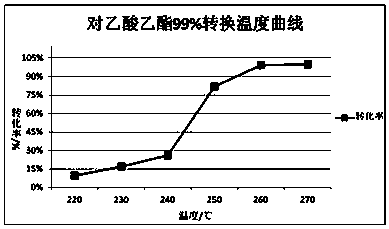

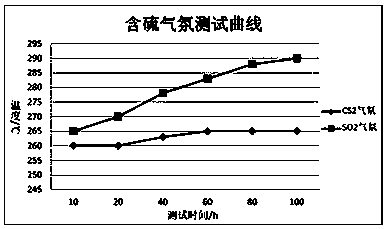

Image

Examples

Embodiment 1

[0021] The preparation method of the present embodiment comprises the following steps:

[0022] A. Weigh a certain amount of Ce(NO 3 ) 3 •6H 2 O and Zr(NO 3 ) 3 • 5H 2 O was dissolved in distilled water, stirred and dissolved for 0.5 hours; then added the prepared NaOH-NH 3 •H 2 O precipitating agent, adjust the pH of the solution to 9; continue to age the solution at 80° C. for 2 hours with stirring to obtain a mixed solution A; the Ce / Zr molar ratio is: 1 / 5;

[0023] B. Add the configured Ag and Mn salt solution to the mixed solution A in step 1, and continue to stir for 0.5 to form a uniform solution B; the Ag / Mn metering ratio is 10:1, and the mass ratio of CeZr solid solution is 1% ;

[0024] C. Slowly add 0.1M precipitant under stirring condition to make the pH value of the system at 9, and then age at 60°C for 1 hour;

[0025] D. The powder obtained after the solution was filtered and dried by suction was immersed in an equal volume of transition metal salt sol...

Embodiment 2

[0029] The preparation method of the present embodiment comprises the following steps:

[0030] A. Weigh a certain amount of Ce(NO 3 ) 3 •6H 2 O and Zr(NO 3 ) 3 • 5H 2 O was dissolved in distilled water, stirred and dissolved for 3 hours; then added the prepared NaOH-NH 3 •H 2 O precipitating agent, adjust the solution pH=14; continue to place the solution at 120° C. for 5 hours under agitation to age to obtain a mixed solution A; the Ce / Zr molar ratio is: 4 / 1;

[0031] B. Add the configured Ag and Mn salt solution to the mixed solution A of step 1, and continue to stir for 3 hours to form a uniform solution B; the Ag / Mn metering ratio is 1:8, and the mass ratio of CeZr solid solution is 4 %;

[0032] C. Slowly add 0.1M precipitant under stirring condition to make the pH value of the system at 14, and then age at 150°C for 5 hours;

[0033] D. The powder obtained after the solution was filtered and dried by suction was immersed in an equal volume of transition metal s...

Embodiment 3

[0037] The preparation method of the present embodiment comprises the following steps:

[0038] A. Weigh a certain amount of Ce(NO 3 ) 3 •6H 2 O and Zr(NO 3 ) 3 • 5H 2 O was dissolved in distilled water, stirred and dissolved for 1 hour; then added the prepared NaOH-NH 3 •H 2 O precipitating agent, adjust the solution pH=10; continue to place the solution at 90° C. for 3 hours under agitation to age to obtain a mixed solution A; the Ce / Zr molar ratio is: 4 / 1;

[0039]B. Add the configured Ag and Mn salt solution to step 1 mixed solution A, and continue to stir for 1 hour to form a uniform solution B; the Ag / Mn metering ratio is 10:1, and the mass ratio of CeZr solid solution is 5 %;

[0040] C. Slowly add 0.1M precipitant under stirring condition to make the pH value of the system at 11, and then age at 80°C for 2 hours;

[0041] D. The powder obtained after the solution was filtered and dried with suction was immersed in an equal volume of transition metal salt solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com