Composite modified epoxy resin structural adhesive, composite modifier and preparation method of structural adhesive

A technology of epoxy resin and structural adhesive, applied in the direction of epoxy resin adhesive, adhesive, adhesive type, etc., can solve the problems of harsh reaction conditions, unfavorable mass production, and high cost of modifiers, and achieve easy on-site construction and curing. The effect of shortening time and increasing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The mass fraction is 2.0-2.5% polyurethane prepolymer compound preparation:

[0027] a. Take 15-16g of polyether polyol, put it into a petri dish with a diameter of 10cm, and dry it under vacuum at 100-110°C for 1-2 hours.

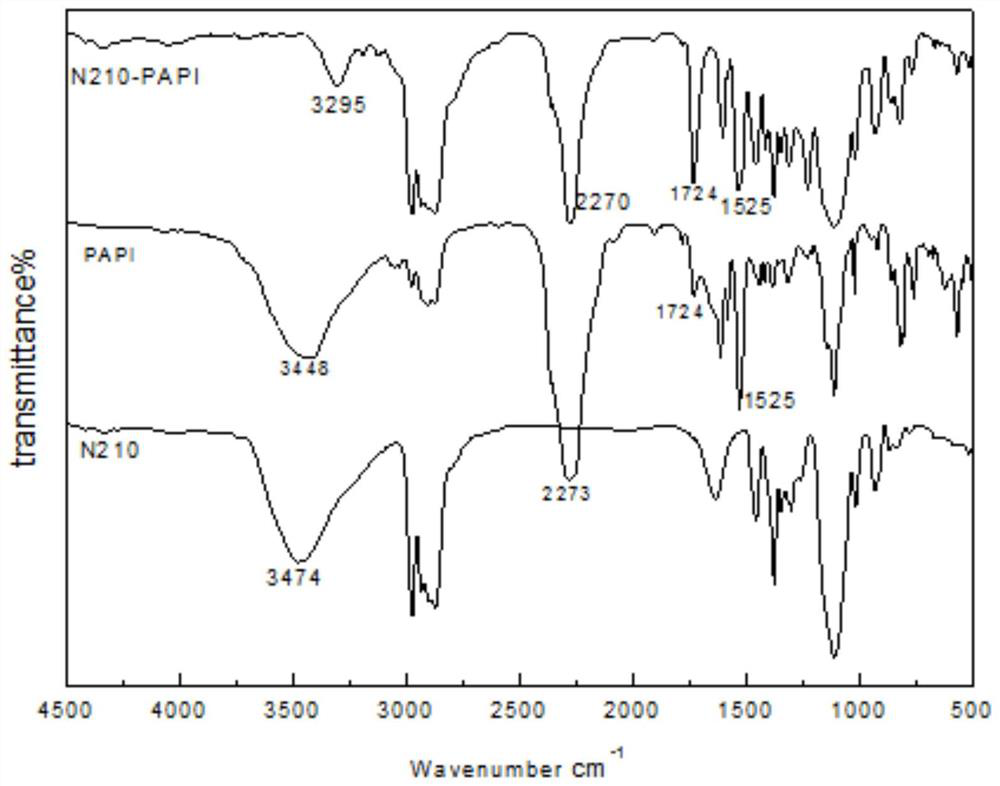

[0028] b. Put the dried polyether polyol and 6-7g of PAPI into a three-necked flask, and react at 50-60° C. for 1-1.5 hours under nitrogen atmosphere. During the reaction, measure the isocyanate content according to the international standard ISO.14896-2009 every 10-20 minutes. When the mass of isocyanate drops to 2.0-2.5%, add the polymerization inhibitor benzoyl chloride and stop after 15 minutes reaction. The measured isocyanate mass fraction is 2.1%, and the obtained component is a polyurethane prepolymer composite of polyether polyol, PAPI, polyurethane prepolymer. The Fourier transform infrared spectrogram of this polyurethane prepolymer composite is as follows figure 2 .

Embodiment 2

[0030] Preparation of epoxy resin structural adhesive with polyurethane prepolymer compound mass fraction of 4%:

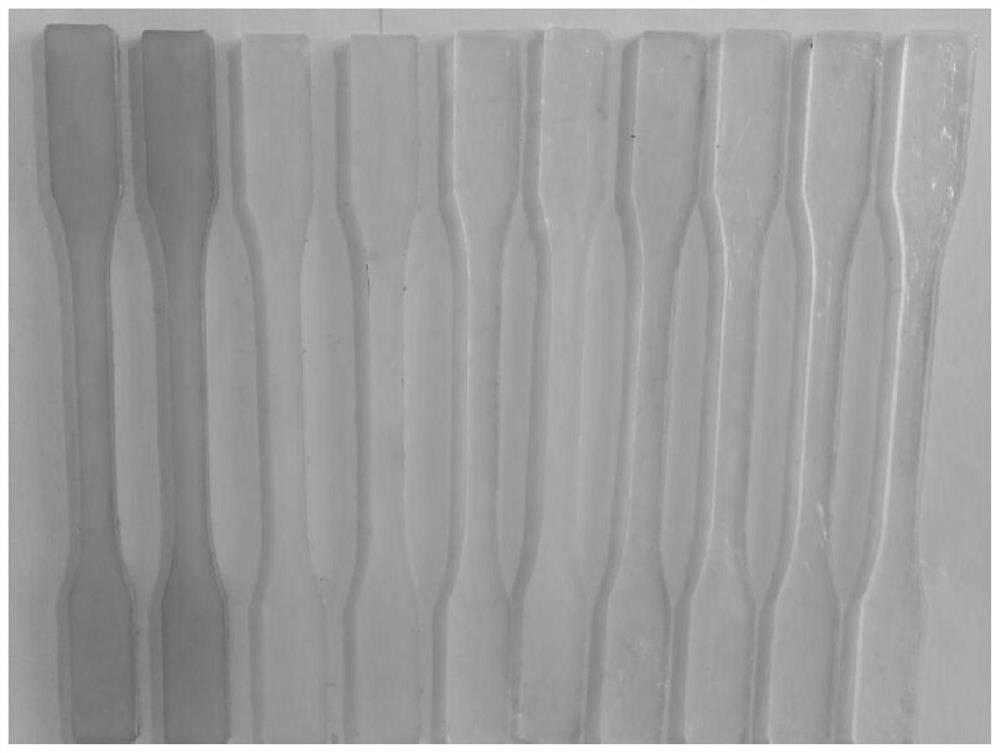

[0031] After fully mixing 0.6g of polyurethane prepolymer compound prepared by implementing 1 with 12.0g bisphenol A type epoxy resin and 1.0g reactive diluent, component A was prepared, and then with 1.4g of component B (curing agent) Mix evenly, pour it into a mold coated with a release agent, let it solidify naturally, it will dry in 30-90 minutes at room temperature, and demould after 24 hours (including 24 hours) after it is completely cured, and the demoulding curing is 120 hours (including 120 hours) Hours) can be tested for mechanical properties. The tensile strength is 30MPa, the tensile shear strength is 14MPa, and the elongation at break is 11%. The scanning electron microscope picture of the tensile fracture surface is as follows image 3 (b).

Embodiment 3

[0033] Preparation of epoxy resin structural adhesive with polyurethane prepolymer compound mass fraction of 9%:

[0034] The polyurethane prepolymer compound 13.5g that example 1 prepares and 110.5g bisphenol A type epoxy resin, 10.0g reactive diluent fully mix and make component A, then with the component B (curing agent) of 16.0g Mix evenly, pour it into a mold coated with a release agent, let it naturally solidify, surface dry at room temperature for 30-90 minutes, demould after 24 hours (including 24 hours) after it is completely cured, and remove the mold for 120 hours (including 120 hours) Hours) can be tested for mechanical properties. The tensile strength is 36MPa, the tensile shear strength is 16MPa, and the elongation at break is 24%. The scanning electron microscope picture of the tensile fracture surface is as follows image 3 (c).

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com