Preparation method of europium-thienoyl trifluoroacetone infinite coordination polymer nanoparticle and its film

A technology of thienoyl trifluoroacetone and coordination polymers, which is applied in the field of rare earth coordination polymers, to achieve the effects of uniform and adjustable size, improved stability and luminous performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

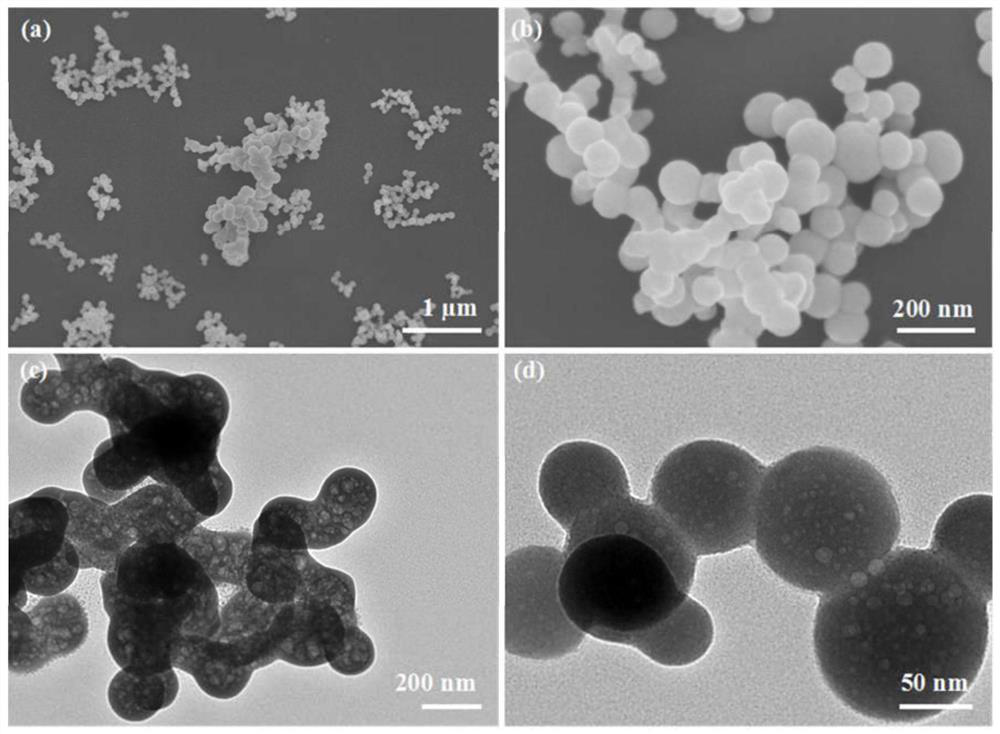

[0025] Example 1: Preparation of Europium-based Infinite Coordination Polymer Nanoparticles

[0026] 0.1mmol Eu(NO 3 ) 3 ·6H 2 O was dissolved in 5 mL of deionized water and stirred to obtain a clear and transparent solution. Add 20 mL of DMF solution dissolved with 0.1 mmol thienoyl trifluoroacetone (HTTA), put the mixed solution in a 40 mL polytetrafluoroethylene-lined stainless steel reaction kettle, and stir with a magnetic suspension stirrer for 10 min. Seal it and heat it in a 160°C electric blast drying oven for 6 hours. After the reaction was completed, it was naturally cooled to room temperature, and washed alternately with deionized water and absolute ethanol three times each. The obtained product was dried in a vacuum oven at 80° C. for 8 hours to obtain white europium-thiophenoyltrifluoroacetone infinite coordination polymer nanoparticles.

Embodiment 2

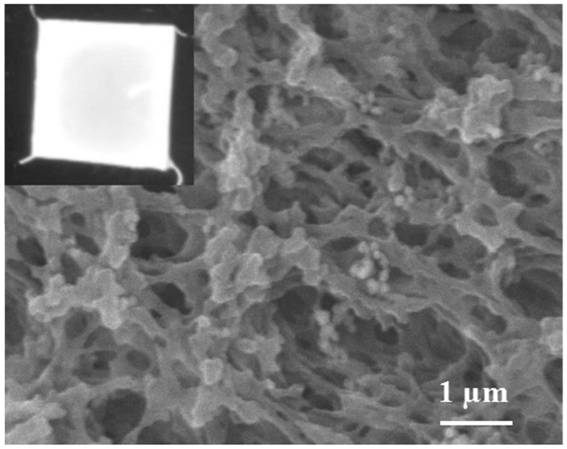

[0027] Example 2: Preparation of rare earth infinite coordination polymer film

[0028] 0.0298 g of the coordination polymer precursor prepared in Example 1 was dissolved in 2.6 mL of DMF solvent, and ultrasonically stirred, so that the sample was evenly dispersed in the DMF solvent. Add 0.4470g polymethyl methacrylate, put it in a stirrer and stir for 12h, set the low speed and high speed of the spin coater to 770r / min and 2220r / min respectively, and set the time to 15s and 20s respectively. Then, the obtained coordination polymer mixed sol was dropped on the sample sheet drop by drop to obtain a spin-coated film, which was air-dried to obtain a sample film at last.

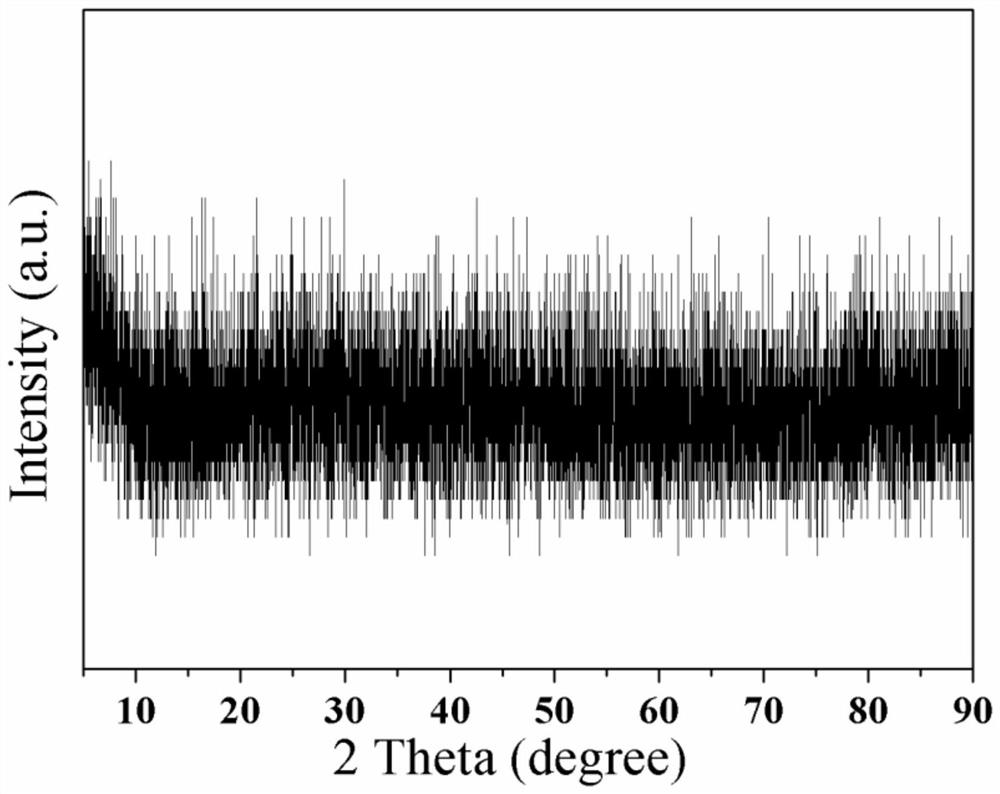

[0029] The products prepared in Examples 1 and 2 were characterized respectively. The XRD pattern is tested and identified on an X-ray diffractometer (Bruker D8ADVANCE, Germany). The SEM image was taken on a scanning electron microscope (S-3400N, 30kV). The transmission electron microscope pictures were obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com