A kind of preparation method and preparation device of au-x nano alloy powder

A technology of powder preparation and nano-alloy, which is applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of high welding material price and complicated process, reduce composition segregation, reduce cost, and facilitate large-scale preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Alloy vacuum smelting: 1000 g and 200 g of Au and Sn metals with a purity of 99.99% are thinned to a thickness of millimeters by rollers, cut into pieces with scissors, and then mixed and placed evenly into the crucible of the vacuum melting furnace, and then evacuated to make the vacuum degree 10 -3 MPa, to prevent its oxidation, then start to heat up, the heating rate is 3°C / min, after the temperature rises to 550°C, the heating rate is 3°C / min, the smelting holding time is 1 h, after the holding, the alloy is naturally cooled with the furnace, The irregular shape of Au-Sn alloy was obtained. Due to its high brittleness, the alloy block was gently broken with a hammer to obtain a small block of Au-Sn alloy with a size less than about 1 cm.

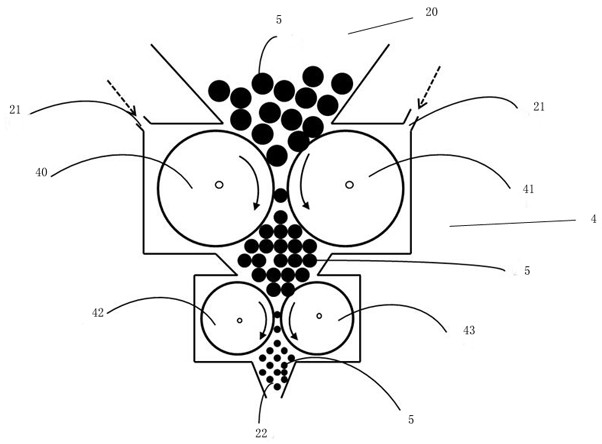

[0022] (2) Crushing under inert atmosphere protection: put the small Au-Sn alloy with a size less than about 1 cm obtained in step 1 into the material inlet (20) of the crushing device, and adjust the top ceramic left pressure...

Embodiment 2

[0026] (1) Alloy vacuum smelting: 1200g, 150g and 150g of Au, Ge and Si with a purity of 99.99% are thinned to a thickness of millimeters by a roller press, and then cut into pieces with scissors, and then They are mixed evenly and placed in the crucible of the vacuum melting furnace, and then vacuumed to a degree of 10 -4 MPa, to prevent its oxidation, then start to heat up at a rate of 4°C / min. After the temperature rises to 610°C, the smelting holding time is 1.5 h. -Si alloy, due to its high brittleness, use a hammer to gently break the alloy block to obtain a small block of Au-Ge-Si alloy with a size less than about 1 cm.

[0027] (2) Crushing under inert atmosphere protection: Put the small Au-Ge-Si alloys with a size less than about 1 cm obtained in step 1 into the material inlet (20) of the crushing device, and adjust the top ceramic left pressure roller of the crushing device ( The pressure roller distance between 40) and the top ceramic right pressure roller (41) is...

Embodiment 3

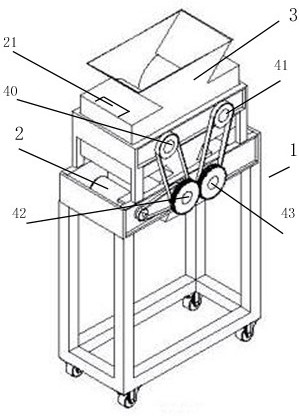

[0031] A crushing device for Au-X nano-alloy powder, comprising a frame body (1), a power device (2) mounted on the frame body, a working chamber (3) and a crushing mechanism (4) disposed in the working chamber. The crushing mechanism (4) set in the working chamber (3), the crushing mechanism (4) includes the top ceramic pressure roller composed of the top ceramic left pressure roller (40) and the top ceramic right pressure roller (41) side by side group, and the bottom ceramic pressure roller group consisting of the bottom ceramic left pressure roller (42) and the bottom ceramic right pressure roller (43) arranged side by side under the top ceramic pressure roller group, the top ceramic left pressure roller The pressure roller distance between (40) and the top ceramic right pressure roller (41) is adjustable, and the pressure roller distance between the bottom ceramic left pressure roller (42) and the bottom ceramic right pressure roller (43) is adjustable; A material inlet (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com