Preparation method of magnetic graphene oxide-protamine/sodium carboxymethyl cellulose composite and application

A technology of sodium carboxymethyl cellulose and protamine, which is applied in the field of material synthesis and biomedicine, can solve the problems of strong interaction between modified molecules and graphene oxide, harmfulness to human body, etc., and achieves easy large-scale production, low cost, The effect of reducing toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

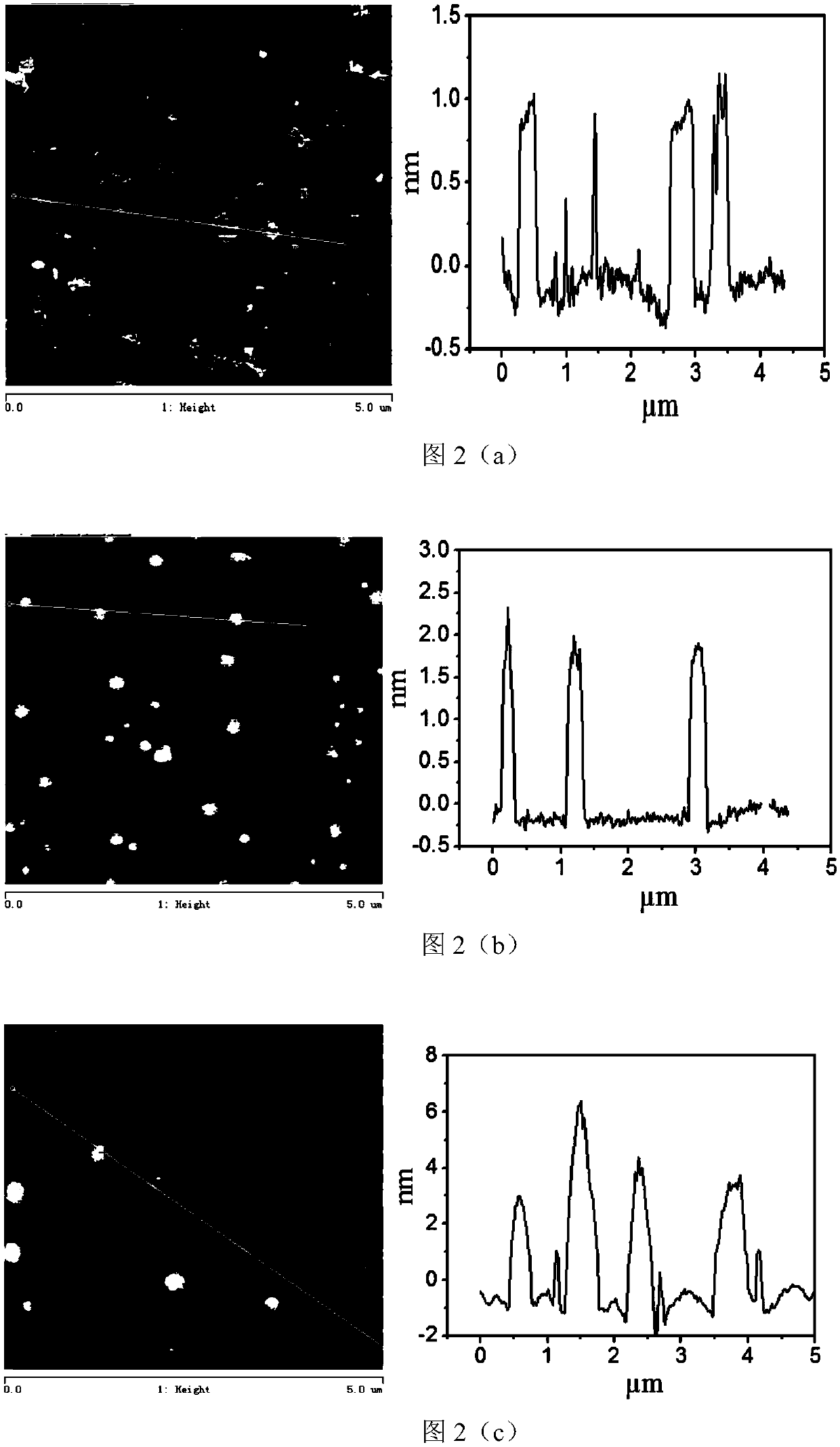

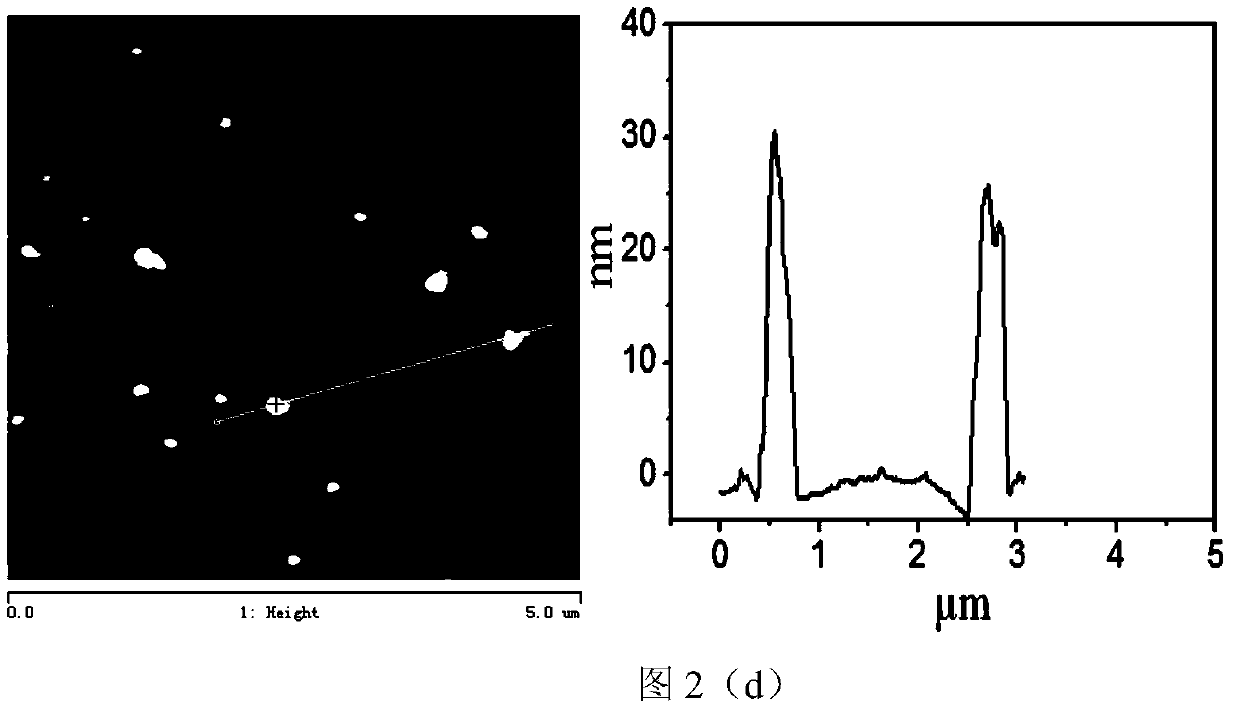

[0034] Embodiment 1: the synthesis of magnetic graphene oxide

[0035] Disperse an appropriate amount of graphene oxide in a mixed solvent of ethylene glycol and diethylene glycol, the concentration of graphene oxide is 2 mg / mL, sonicate the probe in an ice-water bath environment until it is completely dispersed, and then add ferric chloride hexahydrate to the solution , sodium acrylate and sodium acetate, the mass ratio of graphene oxide and ferric chloride hexahydrate is 1:10, the mass ratio of graphene oxide and sodium acrylate is 1:1, and the mass ratio of graphene oxide and sodium acetate is 1: 30. Mechanically stir evenly at room temperature, put the above solution into a reaction kettle, and react at 200°C for 24h. The sample is taken out, and the obtained sample after washing with water and alcohol is magnetic graphene oxide. The sample was dispersed into deionized water, and the magnetic graphene oxide solution was obtained by ultrasonication.

[0036] The magnetic fi...

Embodiment 2

[0038] Disperse an appropriate amount of graphene oxide in a mixed solvent of ethylene glycol and diethylene glycol, and the concentration of graphene oxide is 1 mg / mL. Ultrasonic the probe in an ice-water bath environment until it is completely dispersed, and then add ferric chloride hexahydrate to the solution , sodium acrylate and sodium acetate, the mass ratio of graphene oxide and ferric chloride hexahydrate is 1:15, the mass ratio of graphene oxide and sodium acrylate is 1:5, and the mass ratio of graphene oxide and sodium acetate is 1: 40. Mechanically stir evenly at room temperature, put the above solution into a reaction kettle, and react at 200°C for 24 hours. The sample is taken out, and the obtained sample after washing with water and alcohol is magnetic graphene oxide. The sample was dispersed into deionized water, and the magnetic graphene oxide solution was obtained by ultrasonication.

[0039] The magnetic field investigation results show that the synthesized ...

Embodiment 3

[0041] Disperse an appropriate amount of graphene oxide in a mixed solvent of ethylene glycol and diethylene glycol, the concentration of graphene oxide is 4 mg / mL, sonicate the probe in an ice-water bath environment until it is completely dispersed, and then add ferric chloride hexahydrate to the solution , sodium acrylate and sodium acetate, the mass ratio of graphene oxide and ferric chloride hexahydrate is 1:20, the mass ratio of graphene oxide and sodium acrylate is 1:10, the mass ratio of graphene oxide and sodium acetate is 1: 50, stir mechanically at room temperature, put the above solution into a reaction kettle, and react at 200°C for 24h. The sample is taken out, and the obtained sample after washing with water and alcohol is magnetic graphene oxide. The sample was dispersed into deionized water, and the magnetic graphene oxide solution was obtained by ultrasonication.

[0042] The magnetic field investigation results show that the synthesized magnetic graphene oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com