Micro LED light-emitting display array pixel unit structure and fabrication method thereof

A light-emitting display and pixel unit technology, applied in electrical components, electric solid-state devices, circuits, etc., can solve the problems of low reliability, unfavorable high-density integration of display devices, complex processes, etc., to improve integration density and reliability, high Quality display effect, save the effect of complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] This embodiment provides a method for manufacturing a pixel unit structure of a micro-LED light-emitting display array, the method comprising the following steps:

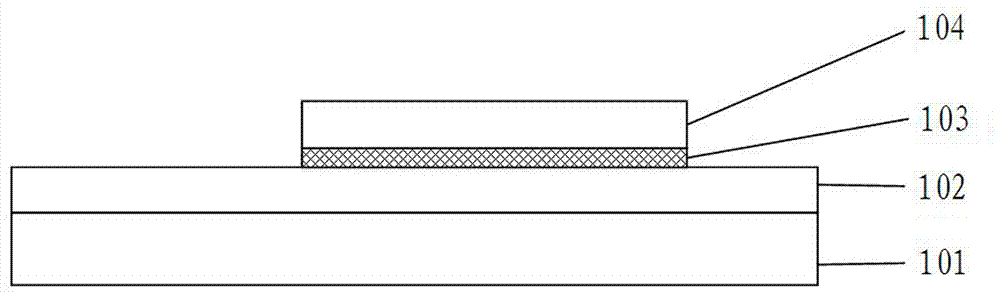

[0076] In step S101, a substrate 101 is provided, and an N-type semiconductor layer 102, an active region layer 103, and a P-type semiconductor layer 104 for forming an epitaxial wafer are sequentially grown upward on the substrate 101, as shown in 2;

[0077] In this embodiment, the substrate may be any material substrate among sapphire, diamond, silicon, gallium arsenide, silicon carbide, and gallium nitride. The growth of the N-type semiconductor layer 102 , the active region layer 103 and the P-type semiconductor layer 104 is realized by MOCVD (Metal Organic Compound Chemical Vapor Deposition) equipment. The material of the semiconductor layer includes but not limited to GaAs, AlGaInP, AlInP, AlGaAs, InGaP, GaP, GaN, InGaN, AlGaN and other materials;

[0078] Step S102, using photolithography and etchin...

Embodiment 2

[0098] This embodiment provides another manufacturing method of a pixel unit structure of a micro-LED light-emitting display array, and the method includes the following steps:

[0099] Step S201 to step S204 are the same as step S101 to step S104 in the first implementation example.

[0100] Step S205, depositing a film with good conductivity on the side where the insulating passivation film is deposited is used to prepare the gate electrode 205 of the thin film transistor, the N electrode 105 of the light emitting diode, the negative electrode 301 of the plate capacitor and the signal line 400, such as Figure 14 shown;

[0101] In this embodiment, the material of the thin film with good conductivity can be metal such as Ti, Ni, Au, Al, Cr, Mo, Pt, Ge, or one or more of oxides such as ITO. The manufacturing method of the ohmic contact electrode thin film can be evaporation or sputtering, and can be realized by etching or stripping process.

[0102] Step S206, depositing a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com