Measuring device for rolling friction force of single sphere

A technology of rolling friction and measuring devices, which is applied in the direction of measuring devices, force/torque/work measuring instruments, mechanical parts testing, etc., and can solve problems such as lack of testing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

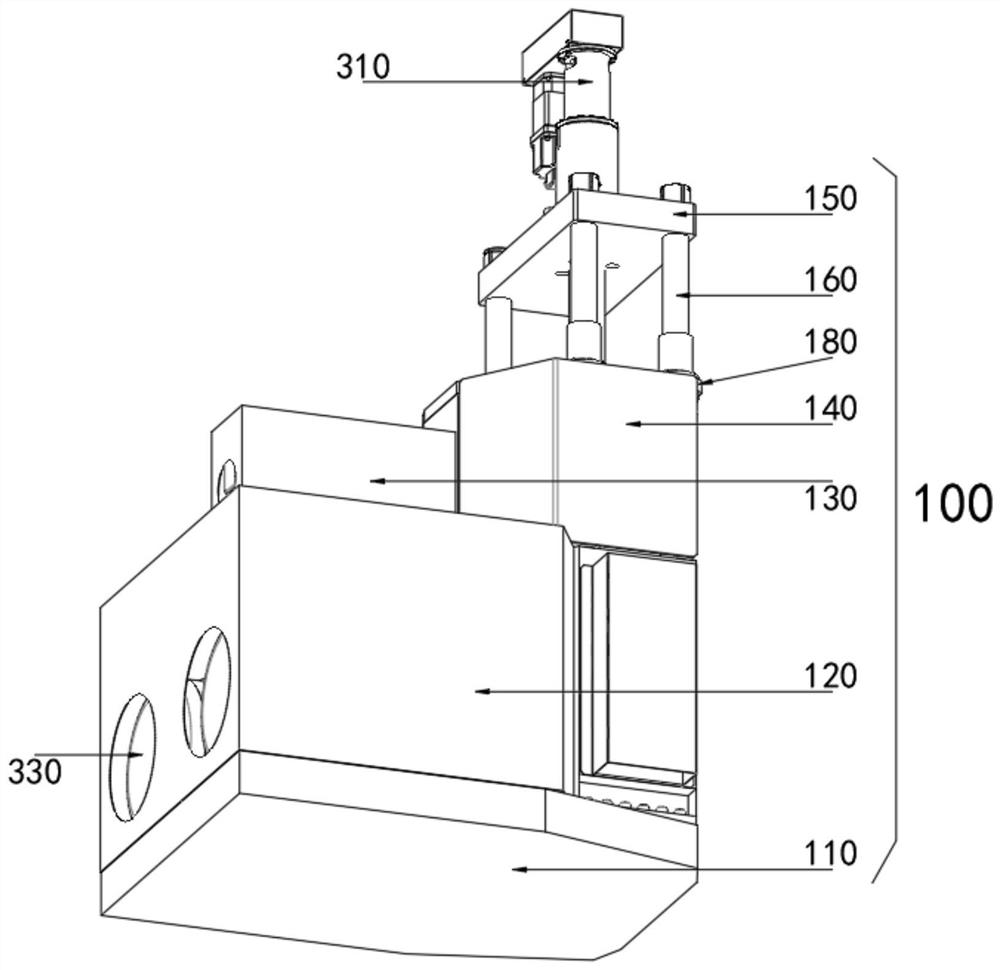

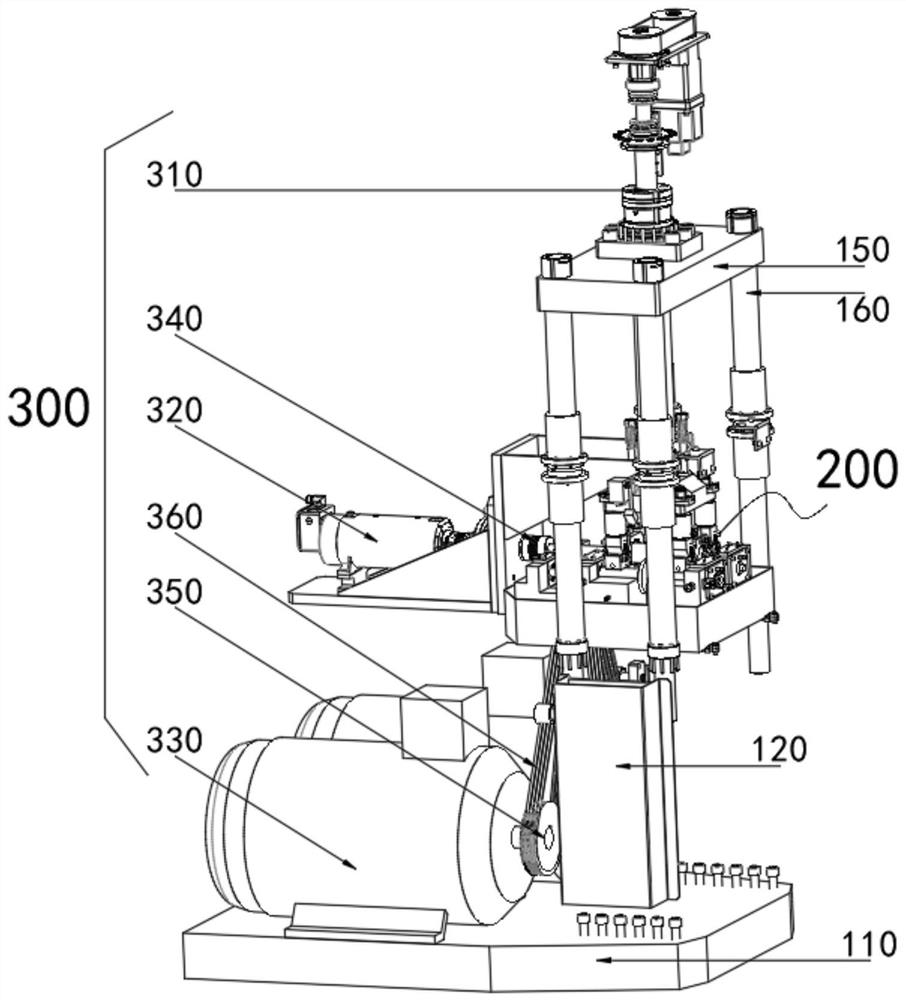

[0032] see Figure 1-Figure 8 , the present invention provides a measuring device for rolling friction of a single sphere, comprising a mounting assembly 100, a testing assembly 200 and a driving assembly 300, the testing assembly 200 and the driving assembly 300 are installed on the side of the mounting assembly 100, the driving assembly 300 and the testing assembly 200 The transmission connection, the installation assembly 100 is used to provide a device installation space, the test assembly 200 is used to measure the friction force of a single ball, and the drive assembly 300 provides power for the test assembly 200 .

[0033] See figure 1 , the mounting assembly 100 includes a shockproof shield 140, an upper horizontal plate 150, a support column 160 and a moving plate 180, the moving plate 180 is slidably arranged on the upper side of the shockproof shield 140, and the support column 160 is fixedly installed on the shockproof shield 140 On the other hand, the upper horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com