Preparation method of evaporation ITO particle and ITO particle prepared through preparation method

A granule, press-forming technology, applied in the field of ITO granules, can solve the problems of small gas flow, large temperature difference in the furnace, and hidden quality problems in mass production of ITO granules, and achieve the effect of reducing gas consumption, fully decomposing and reacting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

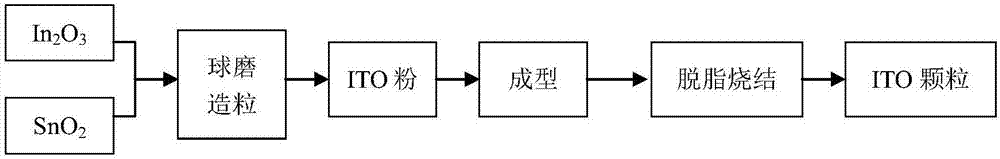

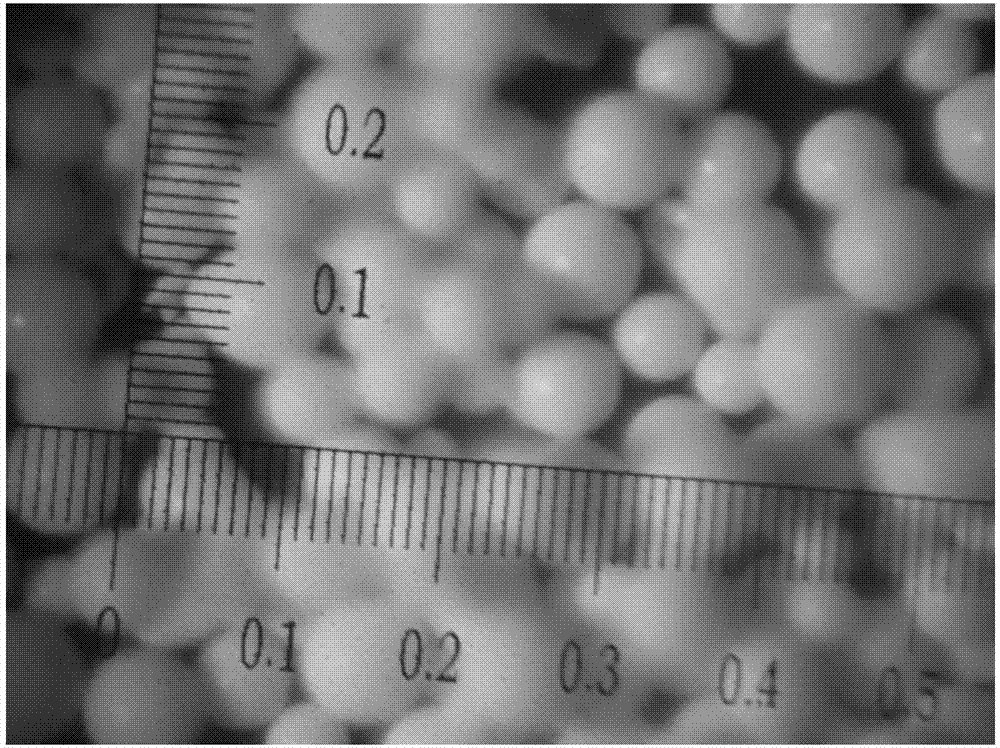

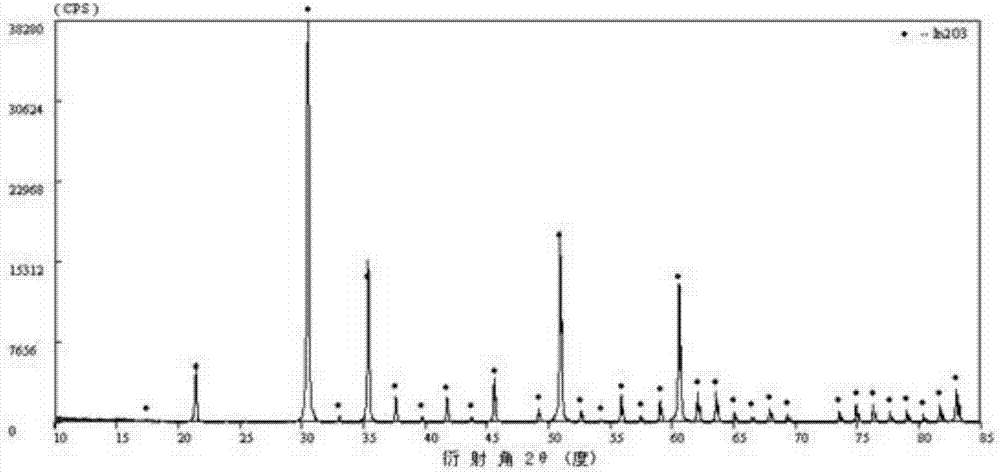

[0039] as per figure 1 As shown in the technological process, weigh 9500 grams of In 2 o 3 Powder (average particle size 65nm, BET 12.80m 2 / g), 500 grams of SnO 2 Powder (average particle size 70nm, BET 12.50m 2 / g), 3586 gram of pure water and 200 gram of dispersants mix to make slurry, dispersant is the aqueous solution of polyacrylate, and its massfraction is 40wt%; Slurry is packed in the ball mill, press slurry and ball Load ZrO with a mass ratio of 1:2 2 Ball, rolling speed 50 rpm, ball milling time 12h; add 600 grams of binder and stir for 60 minutes, then spray granulation, the binder is an aqueous solution of polyvinyl alcohol, and its mass fraction is 10wt%; put ITO powder into In a steel mold or cemented carbide mold with a diameter of 27.5mm, hold the pressure at 25MPa for 1min to press into a disc-shaped ITO green body; put the ITO green body into a pressureless oxygen atmosphere sintering furnace, and first heat it at 60°C / Heating to 200°C at a heating ra...

Embodiment 2

[0041] The preparation of the ITO green body is the same as in Example 1. The ITO green body is put into a pressureless oxygen atmosphere sintering furnace, heated to 200 °C at a heating rate of 100 °C / h, and then heated to 600 °C at a heating rate of 30 °C / h. ℃ for 1h, the oxygen flow rate is 50L / min; then heated to 1400°C at a heating rate of 200°C / h for pressureless oxygen sintering, the sintering time is 5h, the oxygen flow rate is 50L / min; the finally obtained ITO particles are intact, the color It is light green, with a purity of 99.99%, and a relative density of 55.8% obtained by the size method. Through XRD detection, the phase structure is an indium oxide single-phase structure, and the cross-sectional SEM shows that the grain size is 5-10 μm.

Embodiment 3

[0043] Weigh 9800g In 2 o 3 Powder (average particle size 60nm, BET 13.60m 2 / g), 200 grams of SnO 2 Powder (average particle size 85nm, BET 10.35m 2 / g), 3586 grams of pure water and 200 grams of dispersant are packed into the ball mill, and the ITO green body is made by the ball mill mixing, granulation, and molding methods in Example 1, and the ITO green body is packed into a sintering furnace without pressure oxygen atmosphere. In, sintering is carried out by the degreasing sintering method in Example 1. The prepared ITO particles are intact, the color is light green, the purity is 99.99%, and the relative density is 61.7% according to the size method. Through XRD detection, the phase structure is an indium oxide single-phase structure, and the cross-sectional SEM shows that the grain size is 5-8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com