Hydraulic pump spline shaft

A spline shaft and hydraulic pump technology, applied in the field of alloy steel materials, can solve the problems of hydraulic system transmission stability, affecting service life, and speeding up parts, so as to improve the interface bonding method, increase the interface bonding strength, and increase the tensile strength. The effect of degree and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

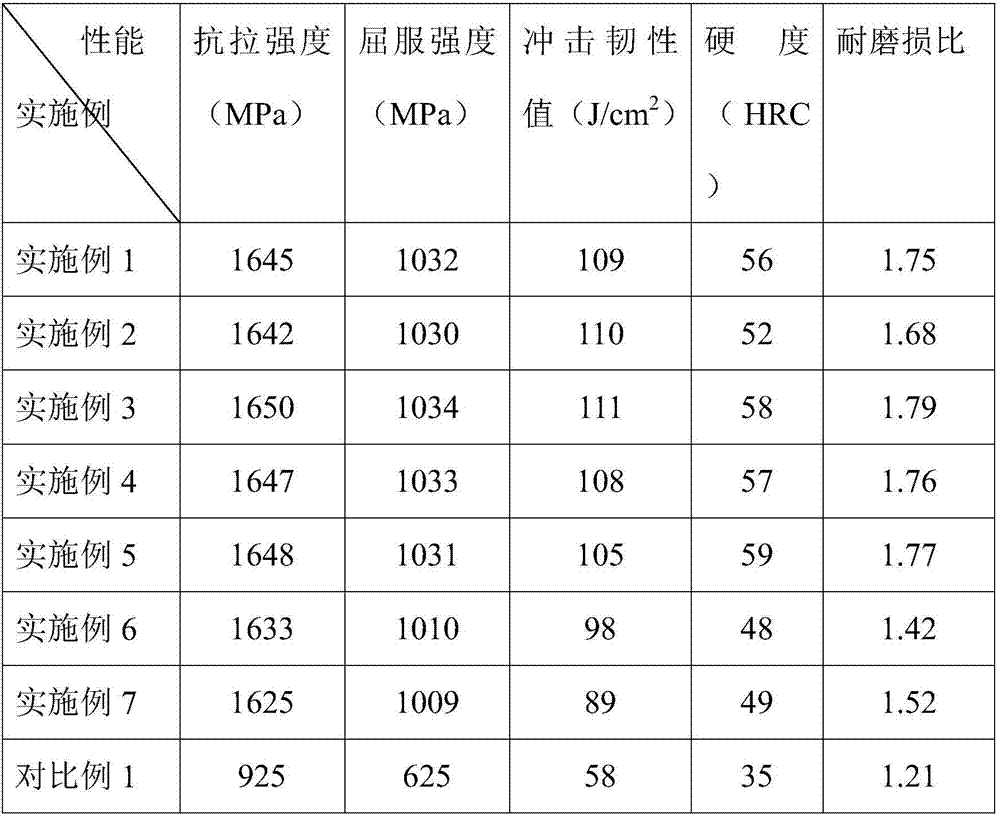

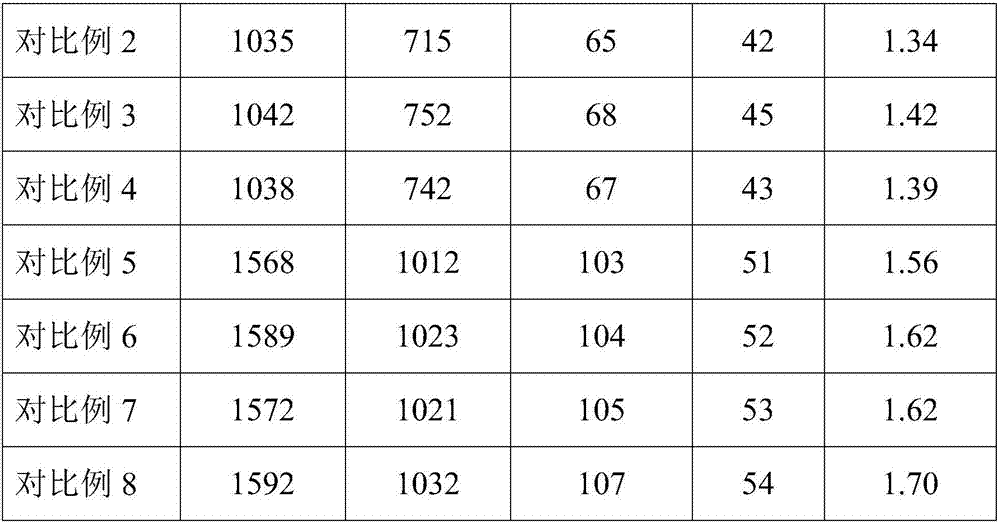

Examples

Embodiment 1

[0028]Press molding: Weigh alloy steel raw materials, ball mill them into powder, and then press them with flake graphite, paraffin, and zinc stearate; wherein, the alloy steel specifically includes the following components by mass percentage: C: 0.99%, Si: 0.26 %, Mn: 0.34%, Cr: 1.8%, Ni: 0.23%, Mo: 0.34%, Nb: 0.65%, and the balance is Fe; the addition of the flake graphite is 0.4% of the quality of the alloy steel raw material, so The add-on of paraffin wax is 0.8% of alloy steel raw material quality, the add-on of described zinc stearate is 0.65% of alloy steel raw material quality; The pressure of compression molding is 625Mpa;

[0029] Pre-firing and cooling: pre-fired at 900°C for 30 minutes in a hydrogen atmosphere, and water-cooled to obtain a pre-fired billet;

[0030] Recompression: Recompress the calcined body and the reinforced phase preform at 725MPa; wherein, the reinforced phase preform is made of TiO 2 Powder, Al 2 o 3 Particles and water glass are prepared ...

Embodiment 2

[0034] Compression molding: Weigh alloy steel raw materials, ball mill them into powder, and then press them with flake graphite, paraffin, and zinc stearate; wherein, the alloy steel specifically includes the following components by mass percentage: C: 1.05%, Si: 0.28 %, Mn: 0.35%, Cr: 1.9%, Ni: 0.25%, Mo: 0.36%, Nb: 0.68%, and the balance is Fe; the addition of the flake graphite is 0.41% of the quality of the alloy steel raw material, so The add-on of paraffin wax is 0.81% of alloy steel raw material quality, the add-on of described zinc stearate is 0.66% of alloy steel raw material quality; The pressure of compression molding is 628Mpa;

[0035] Pre-fired cooling: pre-fired at 908°C for 31 minutes in a hydrogen atmosphere, then water-cooled to obtain a pre-fired billet;

[0036] Recompression: Recompress the calcined body and the reinforced phase preform at 727MPa; wherein, the reinforced phase preform is made of TiO 2 Powder, Al 2 o 3 Particles and water glass are prep...

Embodiment 3

[0040] Compression molding: Weigh alloy steel raw materials, ball mill them into powder, and then press them with flake graphite, paraffin, and zinc stearate; wherein, the alloy steel specifically includes the following components by mass percentage: C: 1.1%, Si: 0.29 %, Mn: 0.36%, Cr: 1.95%, Ni: 0.28%, Mo: 0.38%, Nb: 0.72%, and the balance is Fe; the addition of the flake graphite is 0.43% of the alloy steel raw material quality, so The add-on of paraffin wax is 0.82% of alloy steel raw material quality, the add-on of described zinc stearate is 0.68% of alloy steel raw material quality; The pressure of compression molding is 631Mpa;

[0041] Pre-firing and cooling: pre-fired at 913°C for 32 minutes in a hydrogen atmosphere, and water-cooled to obtain a pre-fired billet;

[0042] Recompression: Recompress the calcined body and the reinforced phase preform at 730MPa; wherein, the reinforced phase preform is made of TiO 2 Powder, Al 2 o 3 Particles and water glass are prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com