Resin matrix of carbon fiber reinforced composite material, carbon fiber reinforced composite material and preparation method thereof, table tennis racket bottom plate

A technology of reinforced composite materials and resin matrix, which is applied in the field of carbon fiber reinforced composite materials, can solve the problems of cumbersome preparation, further improvement of the mechanical properties of composite materials, complex components of resin mixture, etc., and achieve simple raw materials, light weight, and electrical insulation Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The carbon fiber reinforced composite material resin matrix of this embodiment is prepared by the following parts by weight: 100 parts of F46 (648) phenolic epoxy resin, 75 parts of endomethylenetetrahydrophthalic anhydride, and 5 parts of dimethylaniline.

[0045] The carbon fiber-reinforced composite material of this embodiment is mainly made of the above-mentioned carbon fiber-reinforced composite material resin matrix and carbon fiber T300; the mass ratio of carbon fiber and resin matrix in the carbon fiber-reinforced composite material is 60:40.

[0046] The preparation method of the carbon fiber reinforced composite material of the present embodiment comprises the following steps:

[0047] 1) Dissolve the resin matrix of the carbon fiber reinforced composite material in 100 parts of acetone to prepare a glue solution, add the glue solution to the glue tank, and keep the temperature of the glue solution at 30°C;

[0048] 2) The carbon fiber T300 is subjected to ano...

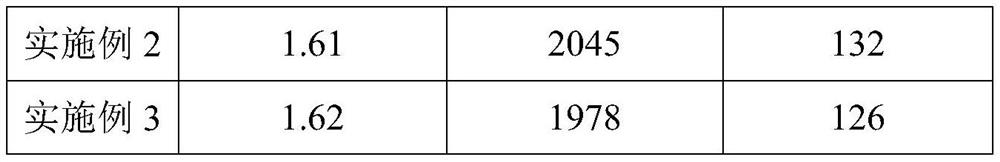

Embodiment 2

[0053] The carbon fiber reinforced composite material resin matrix of the present embodiment is prepared from the following raw materials in parts by weight: 95 parts of F46 (648) phenolic epoxy resin, 70 parts of endomethylenetetrahydrophthalic anhydride, and 4 parts of dimethylaniline .

[0054] The carbon fiber-reinforced composite material of this embodiment is mainly made of the above-mentioned carbon fiber-reinforced composite material resin matrix and carbon fiber T300; the mass ratio of carbon fiber and resin matrix in the carbon fiber-reinforced composite material is 60:40.

[0055] The preparation method of the carbon fiber reinforced composite material of the present embodiment comprises the following steps:

[0056] 1) Dissolve the resin matrix of the carbon fiber reinforced composite material in 110 parts of acetone to prepare a glue solution, add the glue solution to the glue tank, and keep the temperature of the glue solution at 20°C;

[0057] 2) The carbon fib...

Embodiment 3

[0062] The carbon fiber reinforced composite material resin matrix of the present embodiment is prepared from the following raw materials in parts by weight: 105 parts of F46 (648) phenolic epoxy resin, 80 parts of endomethylene tetrahydrophthalic anhydride, and 6 parts of dimethylaniline .

[0063] The carbon fiber-reinforced composite material of this embodiment is mainly made of the above-mentioned carbon fiber-reinforced composite material resin matrix and carbon fiber T300; the mass ratio of carbon fiber and resin matrix in the carbon fiber-reinforced composite material is 60:40.

[0064] The preparation method of the carbon fiber reinforced composite material of the present embodiment comprises the following steps:

[0065] 1) Dissolve the resin matrix of the carbon fiber reinforced composite material in 120 parts of acetone to prepare a glue solution, add the glue solution to the glue tank, and keep the temperature of the glue solution at 25°C;

[0066] 2) The carbon f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com