Sterilization fertilizer particulate agent containing metconazole

A technology of fungicides and granules, applied in the directions of fungicides, biocides, organic fertilizers, etc., can solve the problems of unfavorable agricultural development, increase the labor intensity and labor frequency of farmers, etc. The effect of saving auxiliaries and packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: 0.1% metconazole medicinal fertilizer granule

[0025] Components include: metconazole 0.1%, urea 5%, monoammonium phosphate 2%, potassium chloride 2%, zinc sulfate monohydrate 2%, borax 2%, corn starch 0.5%, polyvinyl alcohol 0.1%, polyethylene Glycol 0.1%, Calcium Bicarbonate 20%, Kaolin make up 100%.

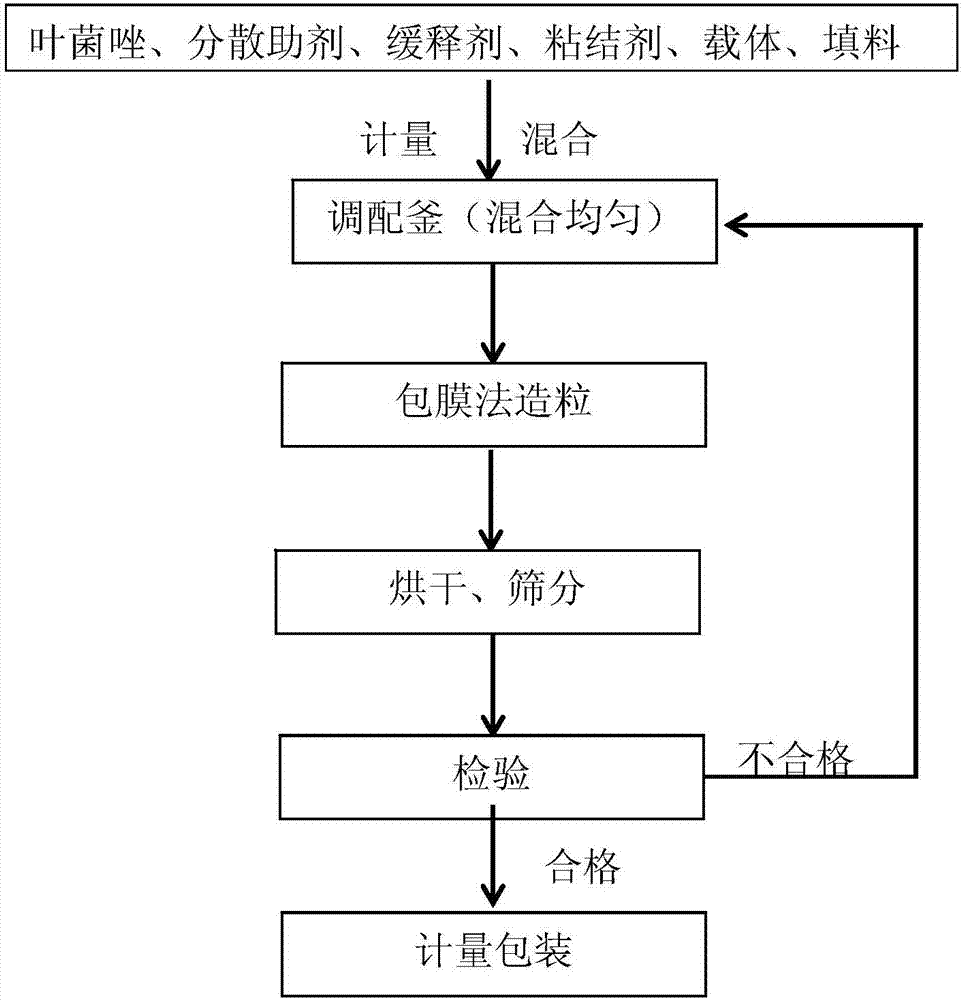

[0026] Preparation process: such as figure 1 As shown, according to the above-mentioned mass percentage of weighing materials, metconazole, urea, monoammonium phosphate, potassium chloride, zinc sulfate monohydrate, borax, corn starch, polyvinyl alcohol, polyethylene glycol, calcium bicarbonate, Kaolin is mixed evenly in a closed mixing kettle, granulated by coating method, dried at 110°C-120°C until the water content of the granules is less than 3%, sieved, and the particle size range is 2000μm-4000μm. After passing the inspection, it can be obtained 0.1% metconazole fertilizer granules.

Embodiment 2

[0027] Embodiment 2: 1% metconazole medicinal fertilizer granule

[0028] Components include: metconazole 1%, urea 25%, monoammonium phosphate 20%, potassium sulfate 10%, zinc sulfate monohydrate 5.5%, borax 8%, sweet potato starch 3%, gum arabic 2%, polyethylene glycol 5%, Calcium Bicarbonate 5%, Kaolin make up 100%.

[0029] Preparation process: such as figure 1 As shown, according to the above-mentioned weight percentage of the material, metconazole, urea, monoammonium phosphate, potassium sulfate, zinc sulfate monohydrate, borax, sweet potato starch, gum arabic, polyethylene glycol, calcium bicarbonate, kaolin in Mix evenly in a closed blending kettle, perform coating granulation, dry at 110°C-120°C until the water content of the granules is less than 3%, sieve, the particle size range is 2000μm-4000μm, and after passing the inspection, you can get 1% Metconazole fertilizer granules.

Embodiment 3

[0030] Embodiment 3: 0.5% metconazole medicinal fertilizer granule

[0031] Components include: metconazole 0.5%, ammonium sulfate 10%, monoammonium phosphate 10%, potassium sulfate 12%, zinc sulfate monohydrate 4%, borax 6%, sweet potato starch 2%, gum arabic 1%, industrial gelatin 3 %, calcium bicarbonate 10%, kaolin make up 100%.

[0032] Preparation process: such as figure 1 As shown, weigh the materials according to the above mass percentage, metconazole, ammonium sulfate, monoammonium phosphate, potassium sulfate, zinc sulfate monohydrate, borax, sweet potato starch, gum arabic, industrial gelatin, calcium bicarbonate, kaolin in a closed Mix evenly in a blending kettle, perform coating granulation, dry at 110°C-120°C until the water content of the granules is less than 3%, sieve, and the particle size range is 2000μm-4000μm. After passing the inspection, you can get 0.5% leaves Conazole fertilizer granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com