Graphene/silicon composite material, preparation method thereof and lithium ion battery

A silicon composite material and graphene technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high initial discharge specific capacity and poor cycle performance of porous graphene/silicon composite materials, and achieve tap density And the specific surface area is improved, the liquid absorption and liquid retention capacity is improved, and the liquid retention capacity is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the graphene / silicon composite material of the present embodiment comprises the following steps:

[0037] 1) Preparation of hydrogel

[0038] Add 20g of 3-aminopropyltriethoxysilane to 1000mL of graphene oxide solution with a concentration of 5mg / mL. After stirring evenly, add 3g of melamine and ultrasonically disperse it evenly. React for 3h, then filter to obtain block hydrogel A;

[0039] 2) vacuum freeze drying

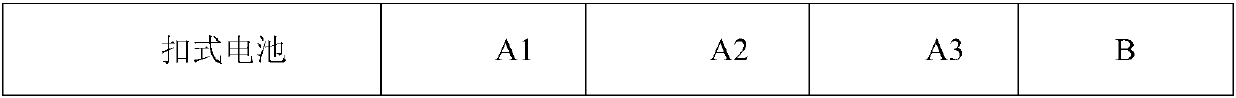

[0040] Place the bulk hydrogel A in a vacuum freeze dryer, evacuate to 20Pa, then cool down the vacuum drying oven to -40°C and keep it warm for 24 hours, then rise to room temperature, crush the material, and briquette to obtain material B;

[0041] 3) Thermal reduction

[0042]Place the material B in a tube furnace, under the protection of argon, raise the temperature to 350°C at a rate of 5°C / min and keep it for 3 hours, then raise the temperature to 850°C at a rate of 5°C / min and keep it for 3 hours, then naturally Cool dow...

Embodiment 2

[0046] The preparation method of the graphene / silicon composite material of the present embodiment comprises the following steps:

[0047] 1) Preparation of hydrogel

[0048] Add 10g of diethylenetriaminopropyltrimethoxysilane to 1000mL of graphene oxide solution with a concentration of 1mg / mL, stir evenly, then add 1g of ammonia water and ultrasonically disperse evenly, then transfer to an autoclave, and React at a temperature of 120°C for 1 hour, and then filter to obtain block hydrogel A;

[0049] 2) vacuum freeze drying

[0050] Put the bulk hydrogel A in a vacuum freeze dryer, evacuate to 5Pa, then cool down the vacuum drying oven to -60°C and keep it warm for 6 hours, then raise the temperature to room temperature, and then crush and briquette the material to obtain the material B;

[0051] 3) Thermal reduction

[0052] Put material B in a tube furnace, under the protection of argon, raise the temperature to 300°C at a rate of 1°C / min and keep it for 1 hour, and then...

Embodiment 3

[0056] The preparation method of the graphene / silicon composite material of the present embodiment comprises the following steps:

[0057] 1) Preparation of hydrogel

[0058] Add 30g of phenyltris(methyl ethyl ketone oxime) silane to 1000mL of graphene oxide solution with a concentration of 10mg / mL, stir evenly, add 5g of pyrrole and ultrasonically disperse evenly, then transfer to the autoclave, And react at a temperature of 150°C for 6 hours, and then filter to obtain block hydrogel A;

[0059] 2) vacuum freeze drying

[0060] Place the bulk hydrogel A in a vacuum freeze dryer, evacuate to 50Pa, then cool down the vacuum drying oven to -20°C and keep it warm for 48 hours, and finally raise the temperature to room temperature, crush the material, briquette the material, and obtain the material B;

[0061] 3) Thermal reduction

[0062] Put material B in a tube furnace, and under the protection of argon, raise the temperature to 400°C at a rate of 10°C / min and keep it for 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com