Preparation method of lithium battery membrane

A lithium battery separator and porous film technology, applied in the field of lithium battery separator preparation, can solve the problems of reducing battery volume specific energy, increasing the weight and thickness of the separator, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The embodiment of the present invention discloses a preparation method of a lithium battery diaphragm, which includes the following steps: adding a precursor compound, a structure-directing agent and hydrochloric acid into the first mixed solution, stirring, and obtaining a sol after alcoholysis reaction, and the first mixed solution The solution includes ethanol and water, and the precursor compound is selected from one or more of ethyl orthosilicate, methyl orthosilicate, silicon tetrachloride, titanium tetrachloride and n-butyl titanate, the The structure-directing agent is a block copolymer; the sol is coated on the surface of the porous membrane, cleaned, and the lithium battery separator after hot-air drying.

[0021] In the present invention, the porous membrane is used as the base membrane, ethyl orthosilicate, methyl orthosilicate, silicon tetrachloride, titanium tetrachloride and n-butyl titanate are used as precursors, and the block copolymer is used as a stru...

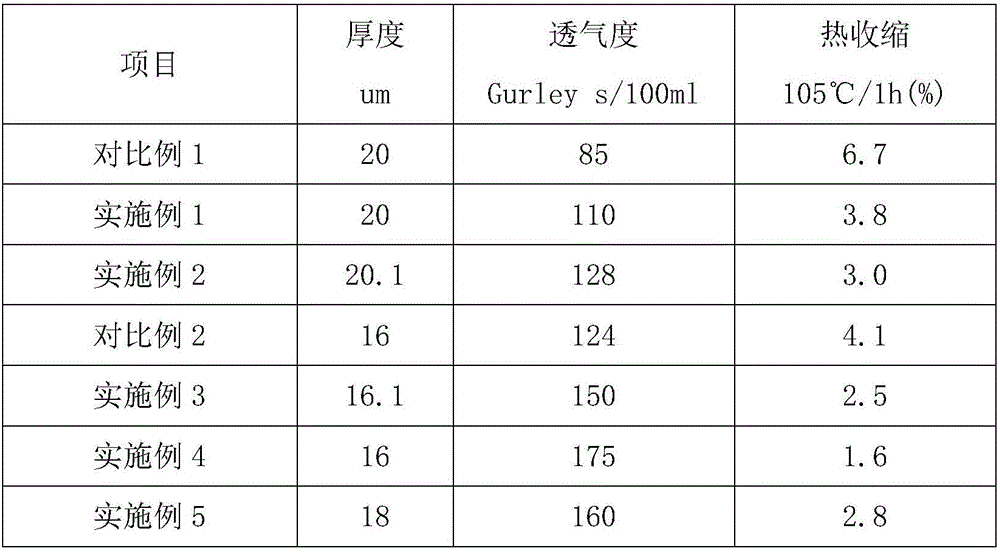

Embodiment 1

[0033] Dissolve 126g of F127 in a mixed solution of 1150ml of ethanol and 360ml of water at 60°C, wait until F127 is completely dissolved, add 110ml of tetraethyl orthosilicate, adjust the pH of the solution to 2-3 by adding hydrochloric acid, and the concentration of HCl in hydrochloric acid is 0.5M , Continue stirring for 2h to complete the reaction to obtain the sol.

[0034] The above-mentioned sol is coated on the PE film by dip coating. The porosity of the PE film is 60%, the average pore diameter is 80nm, the thickness is 20μ, the coating speed is 1m / min, and the surface gel is removed by washing with a mixed solvent of ethanol and water. Dry with hot air at 80°C to obtain a coated separator.

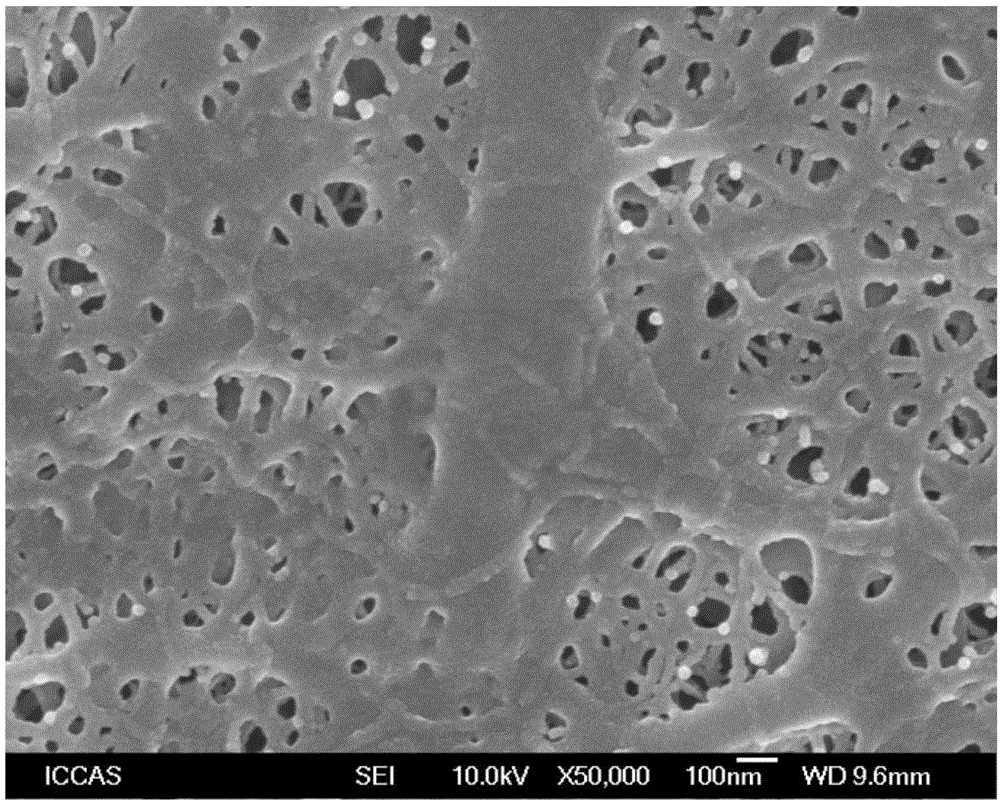

[0035] Carry out SEM analysis to the coating diaphragm that the embodiment of the present invention prepares, as figure 1 Shown is the SEM image of the high-performance interpore coated diaphragm prepared in Example 1.

Embodiment 2

[0037] Dissolve 250g of F127 in a mixed solution of 1200ml of ethanol and 900ml of water at 60°C, wait until F127 is completely dissolved, add 220ml of tetraethyl orthosilicate to the solution, adjust the pH value of the solution to 2-3 by adding hydrochloric acid, the concentration of HCl in hydrochloric acid 1M, and then continue to stir for 2h to complete the reaction to obtain the sol.

[0038] The above-mentioned sol is coated on the PE base film by dip coating. The porosity of the PE film is 60%, the average pore diameter is 80nm, the thickness is 20μ, the coating speed is 1m / min, and the surface gel is removed by washing with a mixed solvent of ethanol and water. , 80 ° C hot air drying to obtain a coated separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com