Preparation method of aromatic tar-reducing cigarette paper

A technology of cigarette paper and tar, which is applied in the field of preparation of flavor-type tar-reduced cigarette paper, which can solve the problems of poor tar-reducing effect, sour taste, and woody gas production of cigarette paper, and achieves improved porosity, enhanced air permeability, and reduced ignition The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

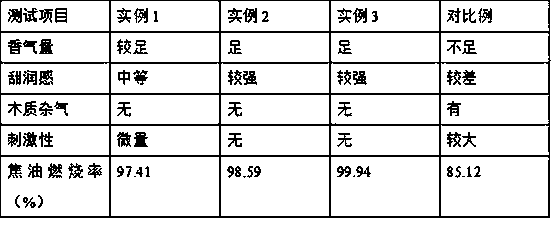

Examples

example 1

[0027]Put the coniferous wood into a pulverizer and pulverize it for 3 hours to obtain sawdust. Put 200g of sawdust and 250mL of water into a beater for beating for 2 hours to obtain coniferous wood pulp. Add 40mL of sodium hydroxide with a mass fraction of 40% to the coniferous wood pulp solution, heated up to 100°C, heat-preserved and cooked for 4 hours, filtered to separate and remove the filtrate to obtain delignified wood pulp; put the above-mentioned delignified wood pulp in a stirred tank, and add 30mL of 5% aluminum chloride solution, start the agitator, stir and mix at a speed of 200r / min for 30min, then feed a mixed gas of propylene and acetyl chloride with a volume ratio of 3:1 into the wood pulp at a ventilation rate of 30mL / min at room temperature , after ventilating for 30min, seal the stirred tank, stir and react for 3h, and obtain the wood pulp that emits aroma; ZnCl with a concentration of 4.0mol / L 2 Solution and CuCl with a concentration of 0.3mol / L 2 Mix th...

example 2

[0029] Put the coniferous wood into a pulverizer for 3.5 hours to obtain wood chips, put 210g of wood chips and 275mL of water into a beater for beating for 2.5 hours to obtain coniferous wood pulp, add 45 mL of hydrogen with a mass fraction of 40% to the coniferous wood pulp Sodium oxide solution, heated up to 105°C, heat-preserved and cooked for 4.5 hours, filtered to separate and remove the filtrate, and obtained delignified wood pulp; put the above-mentioned delignified wood pulp in a stirred tank, and add 35 mL mass fraction of 5% aluminum chloride solution, start the agitator, stir and mix at a speed of 220r / min for 35min, then feed propylene and acetyl chloride into the wood pulp at a ventilation rate of 35mL / min at room temperature with a volume ratio of 3:1 After 32 minutes of ventilation, the stirred tank was sealed and stirred for 3.5 hours to obtain a fragrant wood pulp; ZnCl with a concentration of 4.0mol / L 2 Solution and CuCl with a concentration of 0.3mol / L 2 M...

example 3

[0031] Put the coniferous wood into a pulverizer and pulverize it for 4 hours to obtain sawdust. Put 220g of sawdust and 300mL of water into a beater for beating for 3 hours to obtain coniferous wood pulp. Add 50mL of sodium hydroxide with a mass fraction of 40% to the coniferous wood pulp solution, heated to 110°C, heat-preserved and cooked for 5 hours, filtered to separate and remove the filtrate, and obtained delignified wood pulp; put the above-mentioned delignified wood pulp in a stirred tank, and add 40 mL of aluminum chloride solution, start the agitator, stir and mix at a speed of 250r / min for 40min, then feed a mixed gas of propylene and acetyl chloride with a volume ratio of 3:1 into the wood pulp at a ventilation rate of 40mL / min at room temperature , after ventilating for 35 minutes, seal the stirred tank, stir and react for 4 hours, and obtain the wood pulp that emits aroma; ZnCl with a concentration of 4.0mol / L 2 Solution and CuCl with a concentration of 0.3mol / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com