Compression valve assembly with integrated compensation valve limiter

A technology of compensating valves and stoppers, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problem of abnormal sound of shock absorbers, low cost and production efficiency, and complicated assembly process and other problems to achieve the effect of simplifying installation, improving production efficiency and simplifying assembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

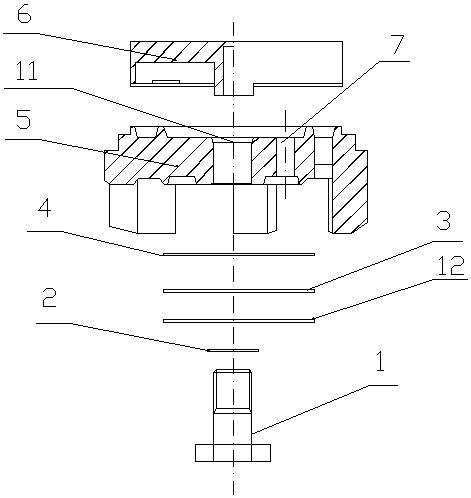

[0025] refer to figure 1 , this embodiment provides a compression valve assembly with an integrated compensation valve stopper, including a compensation valve stopper 6, a compression valve seat 5 and a compression valve screw 1; the compression valve seat 5 is provided with a first threaded through hole 11 and throttle hole 7, the compensation valve stopper 6 is set on one side of the compression valve seat 5, and the compression valve screw 1 is set on the other side of the compression valve seat 5, so After the compression valve screw 1 passes through the gasket 2, the first compression valve plate 12, the second compression valve plate 3, the compression throttle valve plate 4, and the first threaded through hole 11 in sequence, it is limited by the compensation valve Device 6 threaded connection.

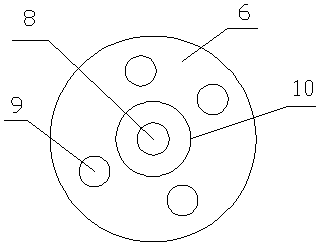

[0026] refer to figure 2 , the surface of the compensation valve stopper 6 is circular, four through holes 9 are evenly arranged on the plane of the compensation valve stopp...

Embodiment 2

[0029] This embodiment provides a compression valve assembly with an integrated compensation valve stopper, which is an improvement on the basis of Embodiment 1: after the compensation valve stopper is connected with the compression valve screw, riveting fixed. The material of the compensation valve limiter is manganese steel alloy.

[0030] The compensation valve limiter and the compression valve screw rod are connected by threads first, and then riveted and fixed by rivets, which is more firm. The material of the compensation valve limiter is manganese steel alloy, which has good mechanical strength, wear resistance and long service life.

Embodiment 3

[0032] This embodiment provides the manganese steel alloy material used for the stopper of the compensation valve.

[0033] The components contained in the manganese steel alloy and their contents are: 70 parts by weight of iron, 15 parts by weight of manganese, 0.9 parts by weight of carbon, 1.2 parts by weight of silicon, 0.01 parts by weight of phosphorus, 1.5 parts by weight of zirconium, 0.2 parts by weight of molybdenum, chromium 0.8 parts by weight and 1.1 parts by weight of cobalt.

[0034] The particle size of the iron powder is 10-40 μm.

[0035] The preparation method of the high manganese steel alloy material comprises the following steps:

[0036] S1: Mix all the raw materials, and then put them into a vacuum furnace for vacuum pre-sintering at a temperature of 100°C for 1 hour to obtain the mixed raw materials;

[0037] S2: Put the mixed raw material obtained in step S1 in a smelting furnace, pass in argon gas, smelt at 700°C for 30 minutes, then pass in hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com