Train carriage joint aerodynamic noise control device and method, and train

An aerodynamic noise and control device technology, applied in railway car body, transportation and packaging, railway car body parts, etc., can solve problems such as abnormal noise at the connection of carriages, and achieve the purpose of solving abnormal noise, prolonging service life, and avoiding cavity resonance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

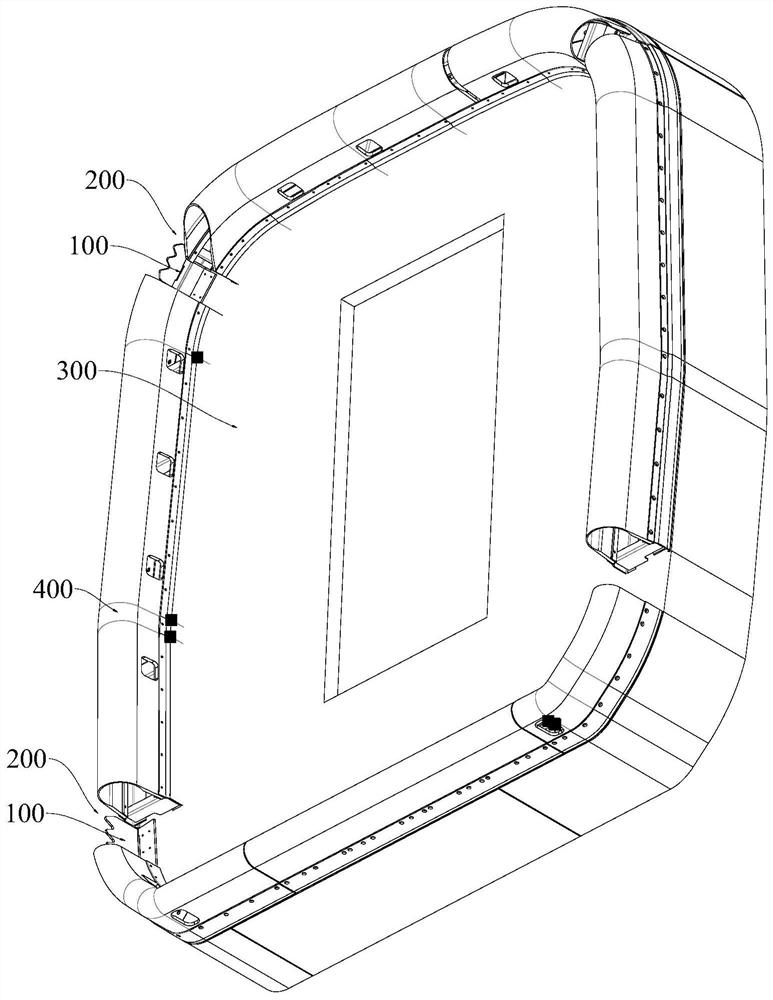

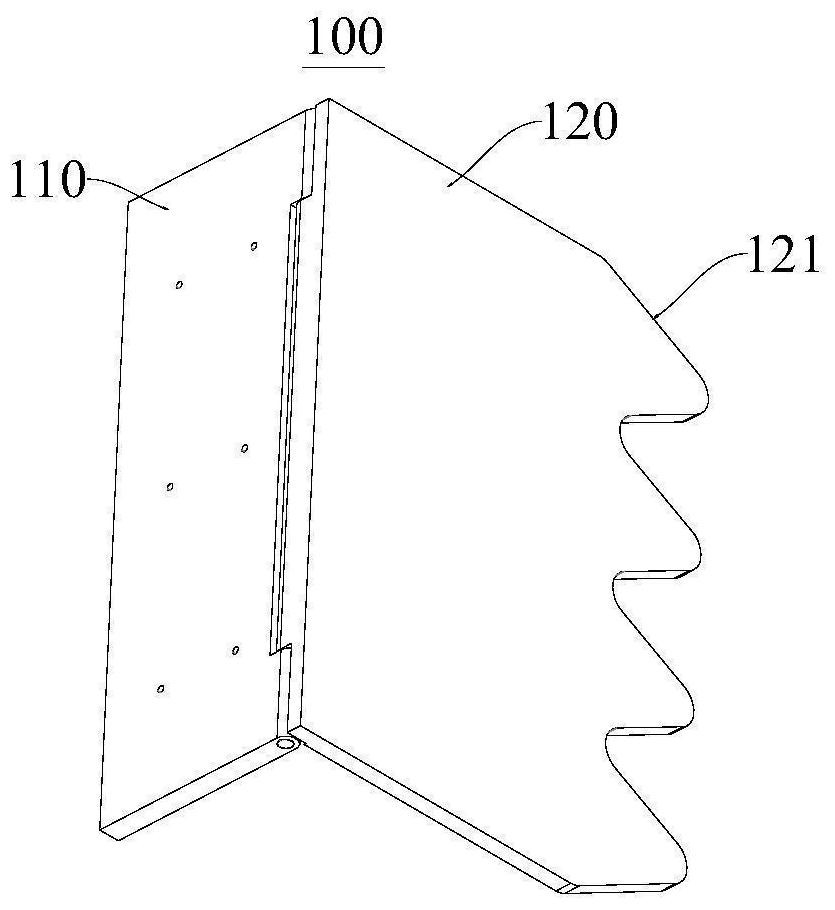

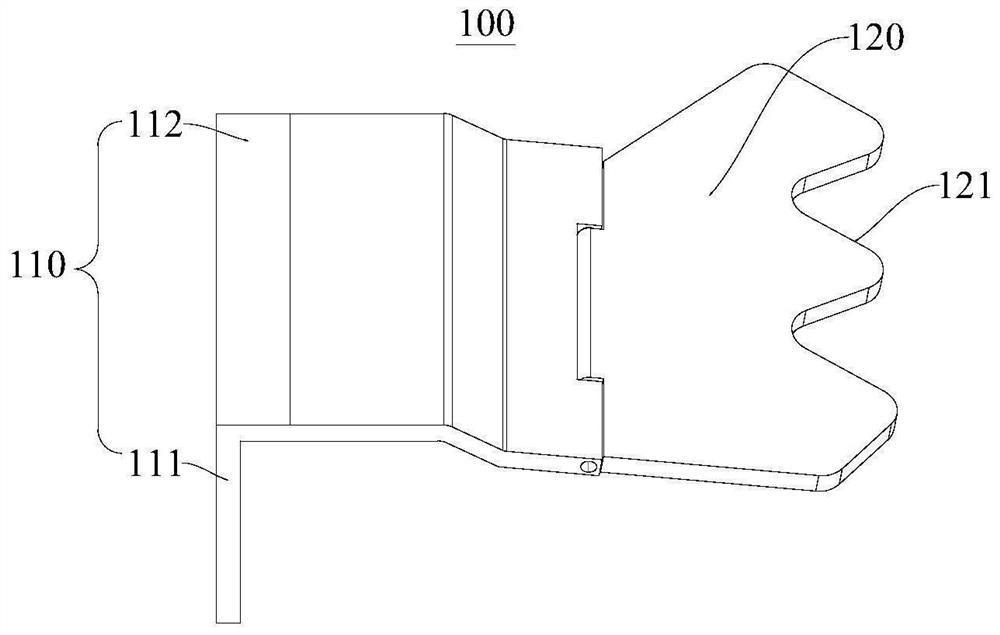

[0040] The simulation analysis of the results of the existing outer windshield shows that the excitation frequency of the aerodynamic noise at the junction of the car is close to the second order of the acoustic mode frequency of the cavity and thus stimulates resonance, which leads to abnormal noise in the mechanic's room inside the car. Analysis of the cloud diagram of the total pulsating pressure level at the junction of the carriages shows that the total pulsation pressure level formed at the rear end of the upper and lower gaps of the windshield at the junction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com