A support frame for mounting a water tank

A technology for installing brackets and water tanks, which is applied to the arrangement of power units, transportation and packaging, and the combination of power unit cooling. It can solve problems such as disassembly troubles, and achieve the effect of easy assembly and maintenance, and easy overall disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

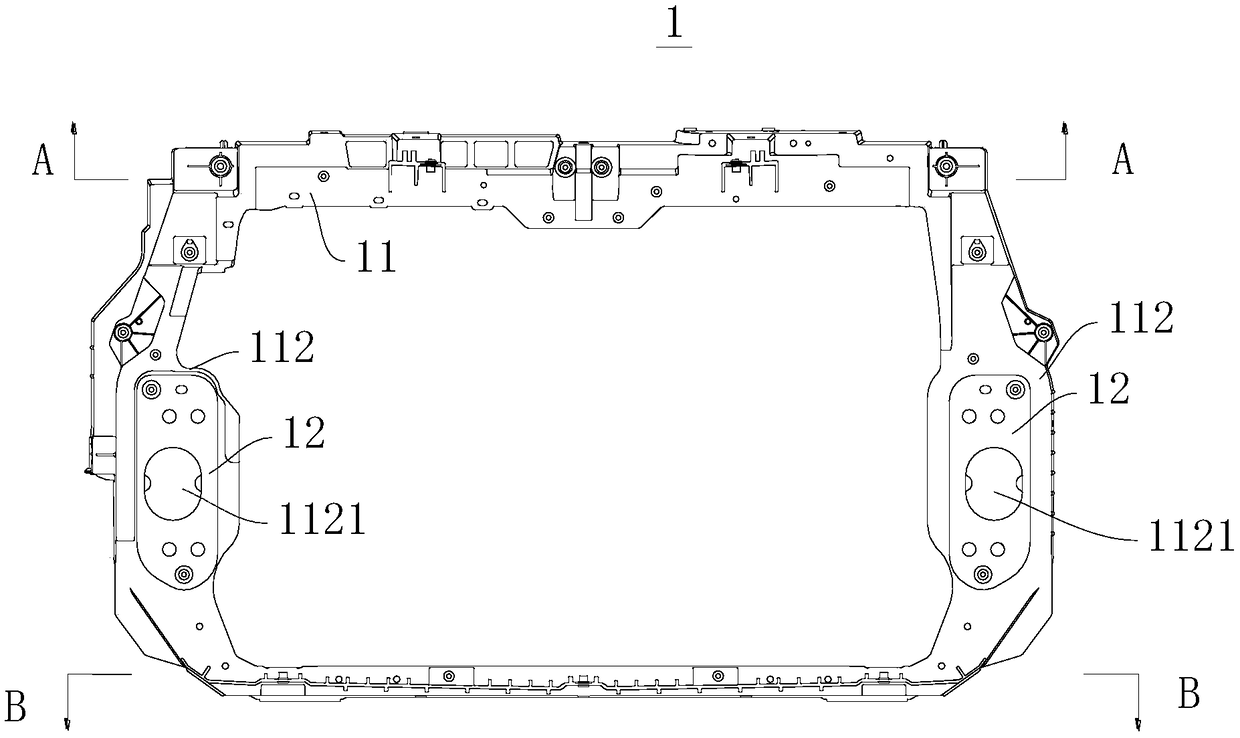

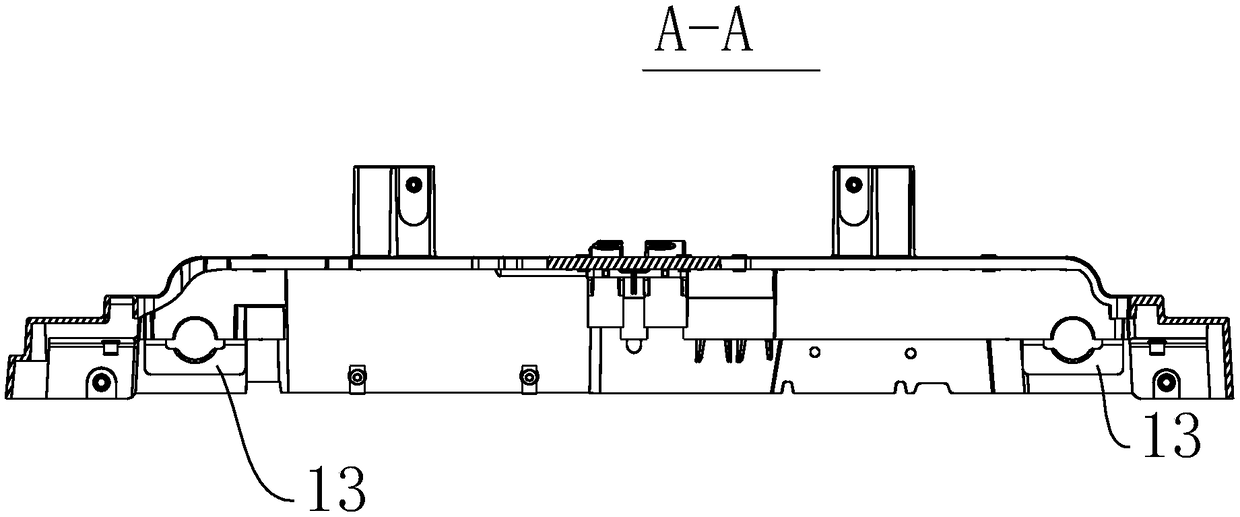

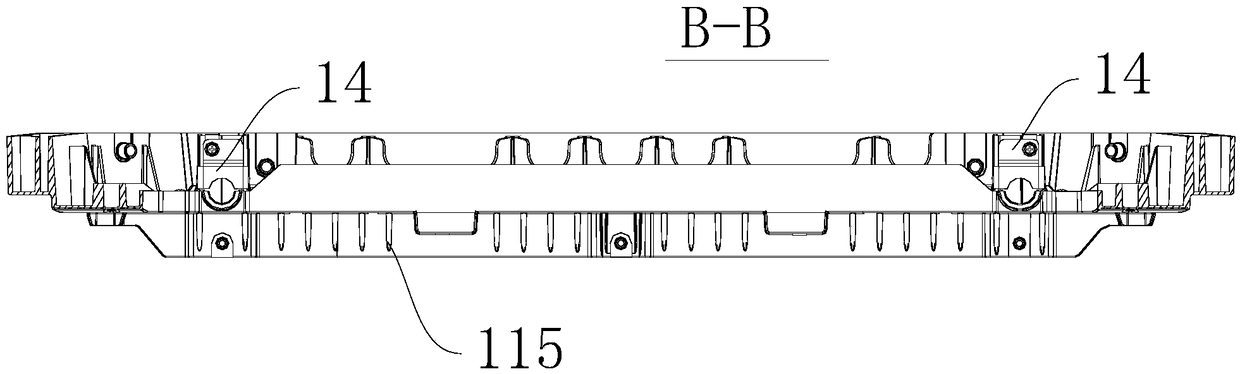

[0039] see Figure 1-Figure 17 . The embodiment of the present invention provides a water tank installation bracket frame 1 .

[0040] This water tank installation bracket frame 1 is frame structure, is made of plastics. The water tank installation bracket frame 1 is used for installing the water tank, and can also be used for installing radiators, anti-collision beams and other parts. The water tank installation bracket frame 1 is used to link to each other with the grid at the front of the car.

[0041] The water tank installation bracket frame 1 includes a base body 11, on which a radiator installation part, an anti-collision beam installation part 112 and a grid connection part are arranged.

[0042] The radiator installation part is used to connect the base body 11 and the radiator, the anti-collision beam installation part 112 is used to connect the anti-collision beam and the base body 11 , and the grid connection is used to connect the base body 11 and the grid toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com