Self-walking shears-fork type high-altitude operation platform walking hydraulic system

A high-altitude work platform and hydraulic system technology, which is applied in the direction of fluid pressure actuators, lifting devices, servo motors, etc., can solve problems such as slipping and impact, and achieve the effect of increasing service life and improving operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

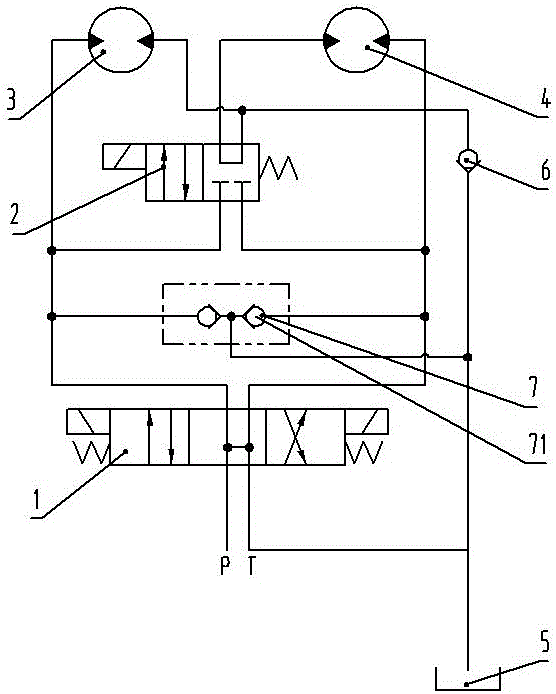

[0014] Such as figure 1 As shown, a self-propelled scissor type aerial work platform walking hydraulic system includes a three-position four-way valve 1, a two-position four-way valve 2, a left travel motor 3, a right travel motor 4 and a hydraulic oil tank 5; The four oil ports in the middle position of the three-position four-way valve 1 are connected to each other, and the oil inlet and oil return circuits of the other two are reversed; the right position of the two-position four-way valve 2 makes the left travel motor 3 and the right travel Motor 4 is connected in series; when two travel motors are connected in series, the high-pressure oil in the system passes through three-position four-way valve 1, left travel motor 3, two-position four-way valve 2, right travel motor 4, and finally passes through three-position four-way valve The four-way valve 1 returns to the hydraulic oil tank 5 . The oil path between the left travel motor 3 and the right travel motor 4 is provided...

Embodiment 2

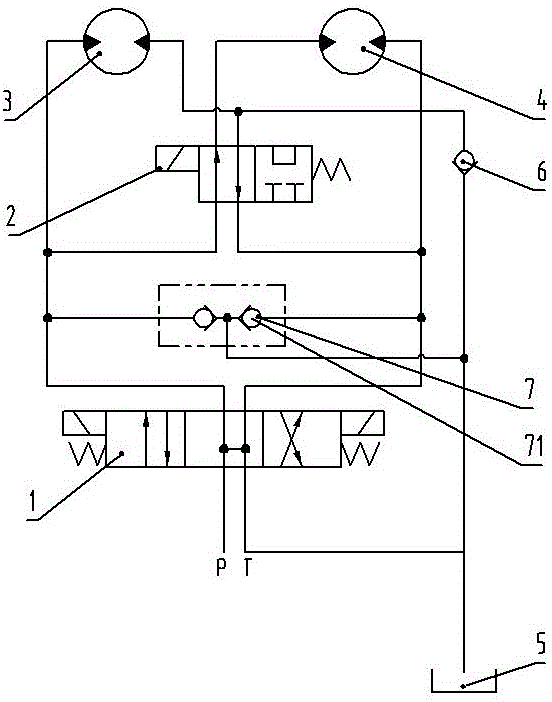

[0017] Such as figure 2 As shown, a self-propelled scissor type aerial work platform walking hydraulic system includes a three-position four-way valve 1, a two-position four-way valve 2, a left travel motor 3, a right travel motor 4 and a hydraulic oil tank 5; The four oil ports in the middle position of the three-position four-way valve 1 are connected to each other, and the oil inlet and oil return circuits of the other two are reversed; the right position of the two-position four-way valve 2 makes the left travel motor 3 and the right travel The motor 4 is connected in series; when two travel motors are connected in parallel and the three-position four-way valve 1 is left, the high-pressure oil in the system passes through the three-position four-way valve 1 and then is divided into two oils which pass through the two-position four-way valve 2 and the left side respectively. Traveling motor 3, the oil passing through the two-position four-way valve 2 passes through the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com