Method for regenerating organic amine desulfurizer by bipolar membrane electrodialysis

A bipolar membrane electrodialysis, organic amine technology, applied in electrodialysis, separation methods, chemical instruments and methods, etc., can solve the problems of difficult operation, unstable sulfurous acid, waste of resources, etc., and achieve simplified operation procedures and stable operation. The effect of sexual enhancement and conductivity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

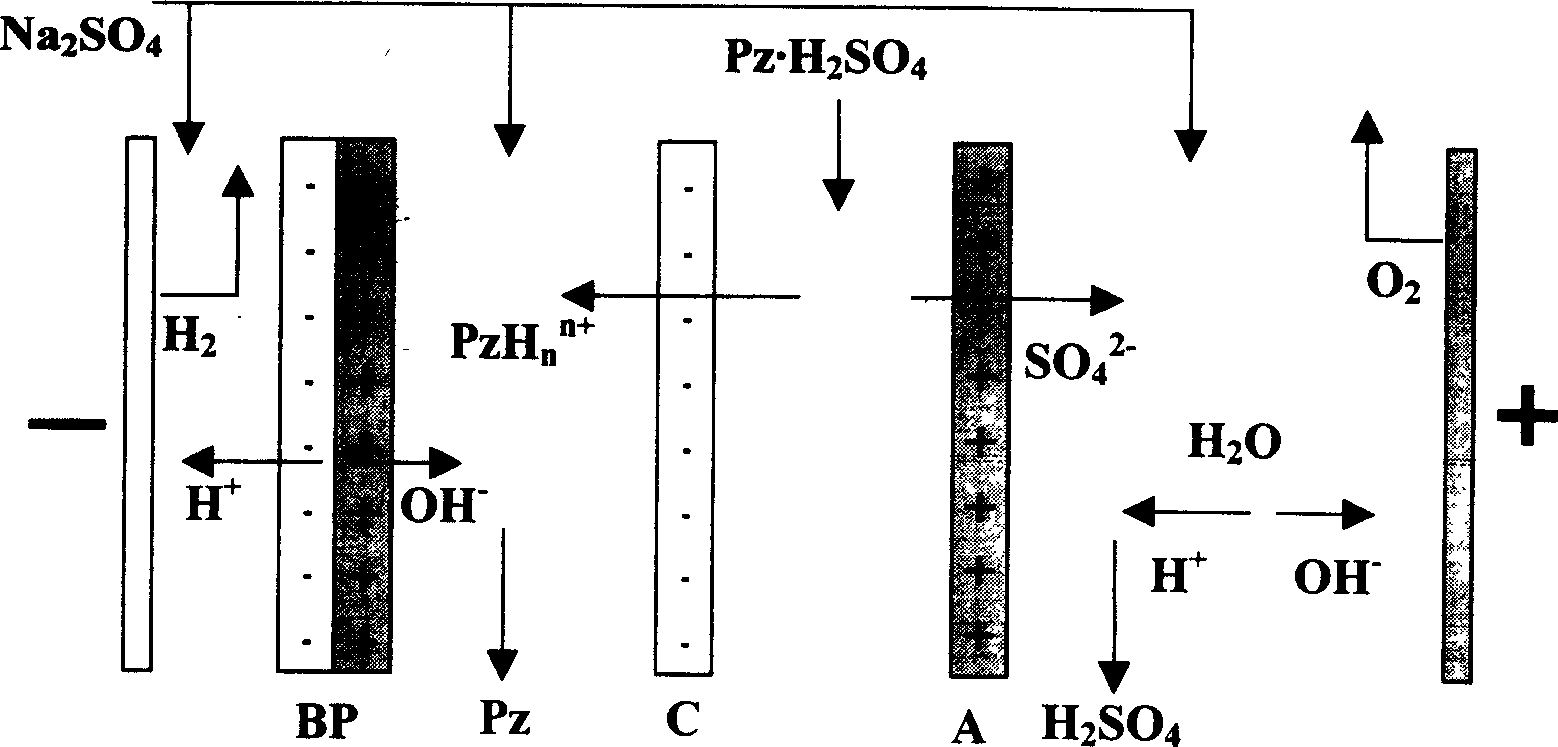

[0015] according to figure 1 The bipolar membrane electrodialysis device with the configuration of BP-C-A membrane cell assembled as shown, that is, titanium ruthenium-coated electrode, plexiglass plate, plexiglass separator, The fluorinated rubber gasket, the bipolar membrane (BP), the cation exchange membrane (C) and the anion exchange membrane (A) are assembled into a bipolar membrane electrodialysis device with a membrane cell repeating unit, forming four corresponding compartments respectively Cathode compartment, alkali compartment, salt compartment and anode compartment, the volume of each compartment is 6.3cm 3 . Each compartment is then connected to an external submersible pump and a beaker (1000mL) through latex tubes to form four independent circulation loops. The cathode chamber, the alkali chamber and the anode chamber are perfused with sodium sulfate (Na 2 SO 4 ) solution, the salt chamber perfusion concentration is 0.18mol / L, and the solution volume is 0.5L ...

Embodiment 2

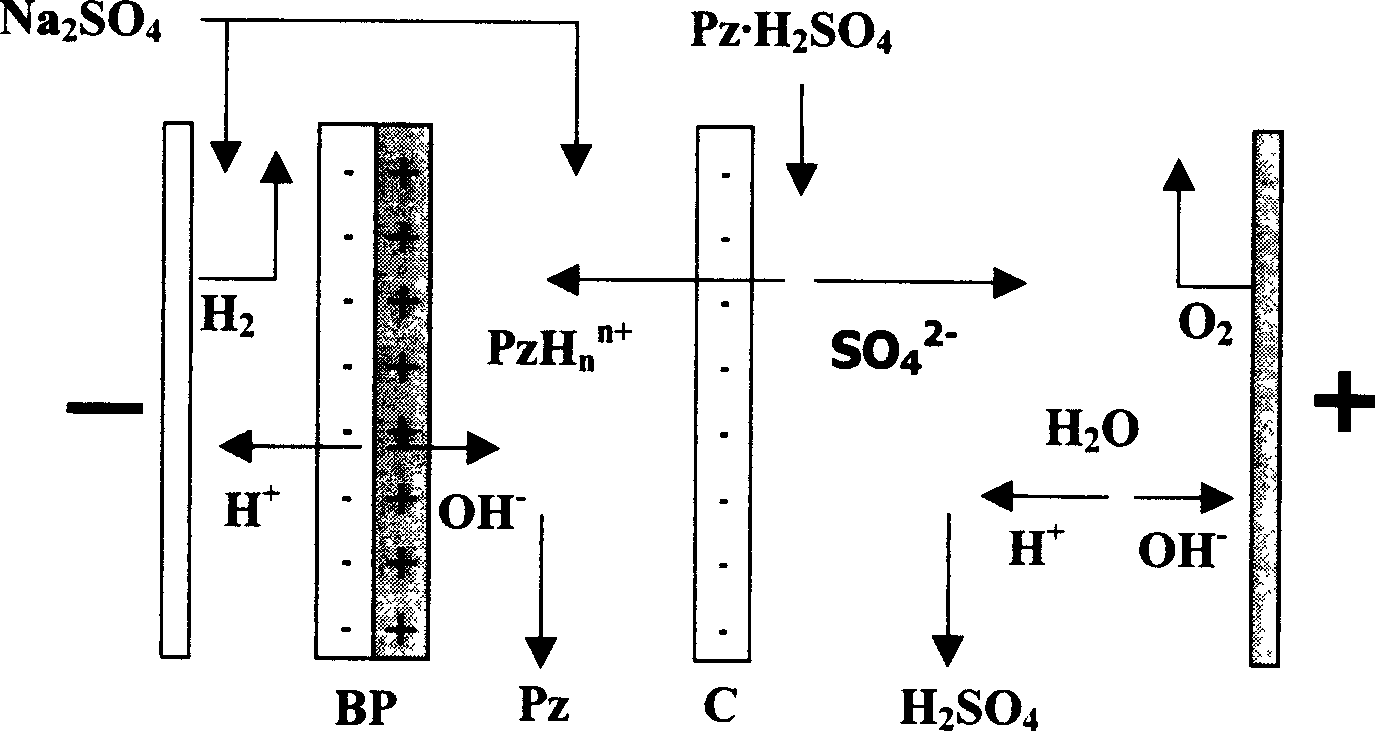

[0018] Similar to the membrane cell assembly steps of Example 1, press figure 2 As shown, a BP-C membrane cell configuration bipolar membrane electrodialysis device assembled with a membrane cell repeating unit forms three corresponding compartments, respectively a cathode compartment, an alkali compartment and an anode compartment. Both the cathode chamber and the alkali chamber are filled with sodium sulfate (NaSO4) with a concentration of 0.3mol / L and a solution volume of 0.5L 2 SO 4 ) solution, the piperazine sulfate (Pz·H 2 SO 4 ) solution, the solutions of the three compartments circulate independently. Other operating conditions are identical with embodiment 1.

[0019] Using this device to regenerate piperazine, the concentration of piperazine in the alkali chamber will reach 0.015mol / L after 1 hour of electrification.

Embodiment 3

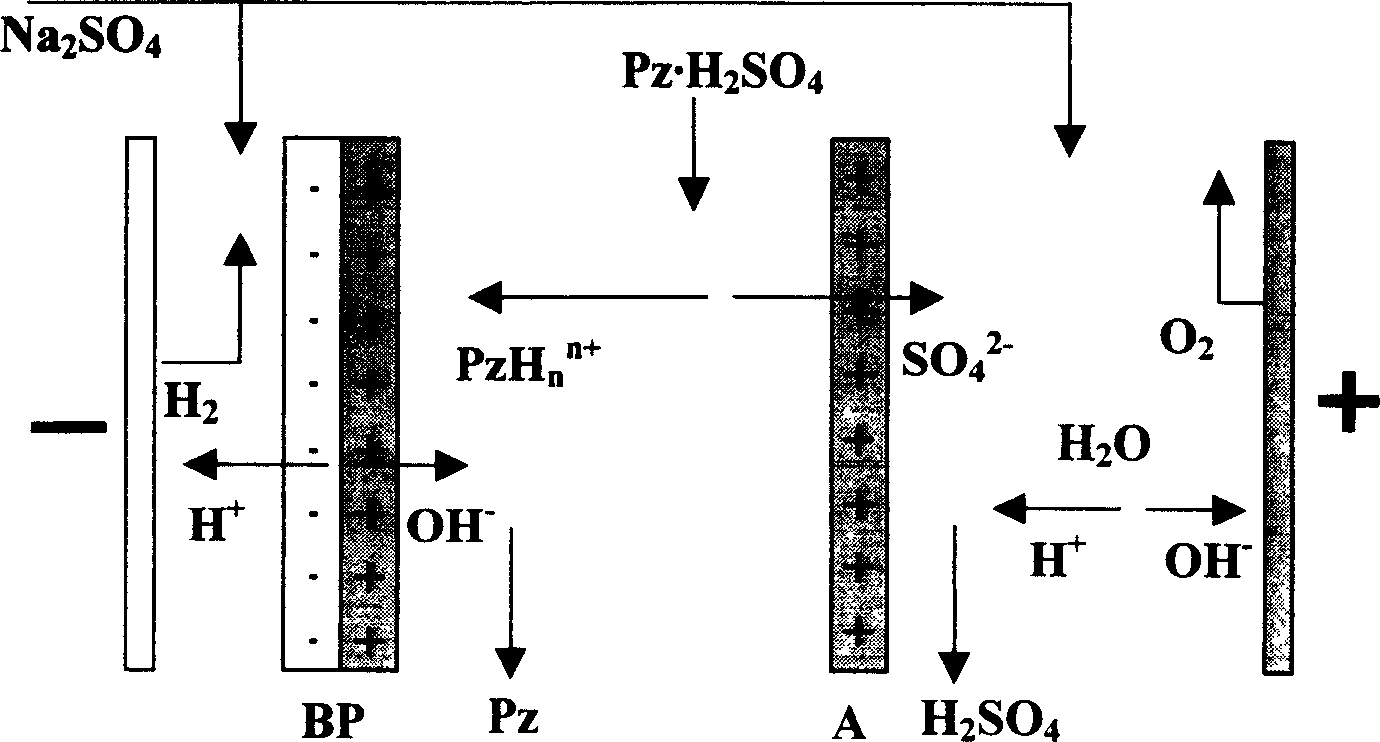

[0021] Similar to the assembly steps of embodiment 1, press image 3 As shown, a BP-A membrane cell configuration bipolar membrane electrodialysis device assembled with a membrane cell repeating unit forms three corresponding compartments, namely a cathode compartment, a salt / alkali compartment and an anode compartment. Both the cathode chamber and the anode chamber were perfused with sodium sulfate (Na 2 SO 4 ) solution, the salt / alkali chamber perfusion is 0.18mol / L, and the solution volume is 0.5L piperazine sulfate (Pz H 2 SO 4 ) solution, the solutions of the three compartments circulate independently. Other operating conditions are identical with embodiment 1.

[0022] Use this device to regenerate piperazine, and the concentration of piperazine in the base chamber will reach 0.005mol / L after 1 hour of electrification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com