Aqueous concrete anti-carbonization coating

An anti-carbonation and concrete technology, applied in the direction of coating, etc., can solve the problem of weakening the protective effect of steel bars, and achieve the effect of preventing carbonation reaction, beautiful concrete structure, and preventing the intrusion of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a preparation process of a water-based concrete anti-carbonization paint primer, intermediate paint and top coat.

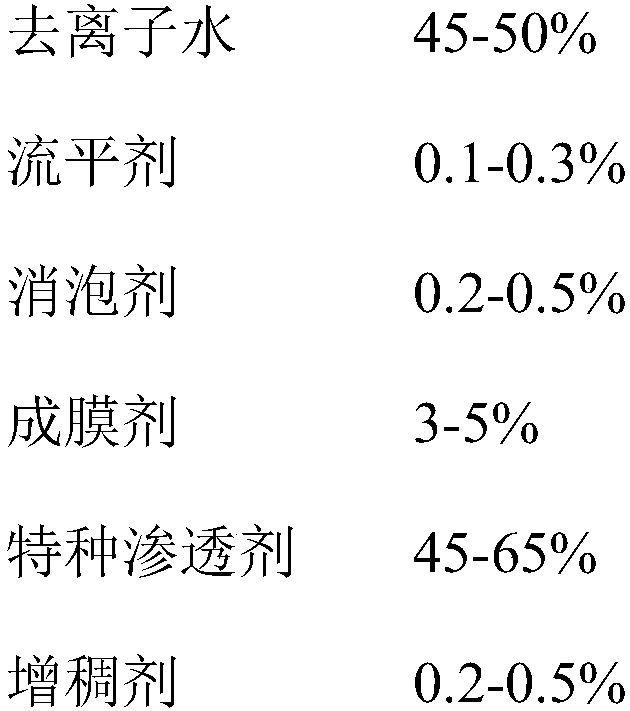

[0030] The primer is 450kg of deionized water, 2kg of polyether polyurethane associative rheology aid with 25% solid content, 3kg of defoaming agent, and 30kg of lauryl alcohol fat. Mix evenly at a speed of 600-800rpm, and then slowly add special penetration Mix 500kg of thickener evenly, add 2kg of thickener after about 30 minutes, continue to stir at a constant speed for 30 minutes, measure its pH value to 7-8, and its viscosity to be 82KU.

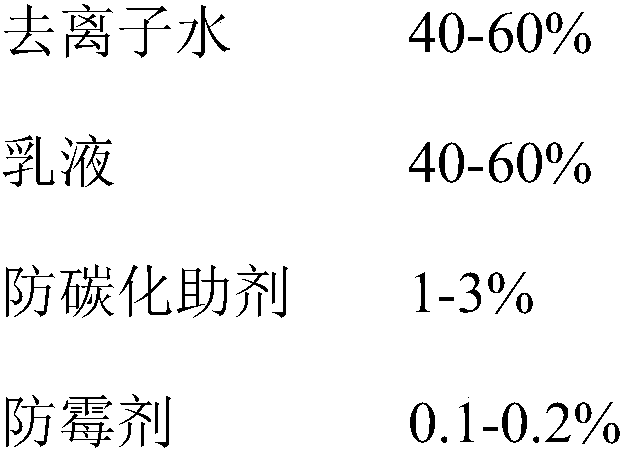

[0031] The middle layer paint is two-component, component A is mixed with 100kg of deionized water, 150kg of emulsion, 15kg of anti-carbonization additive, and 0.5kg of anti-fungal agent. Component B is mixed evenly with 500kg of special cement, 500kg of quartz sand, and 2kg of nano-scale silicate reinforcing agent. Where A:B=1:4.

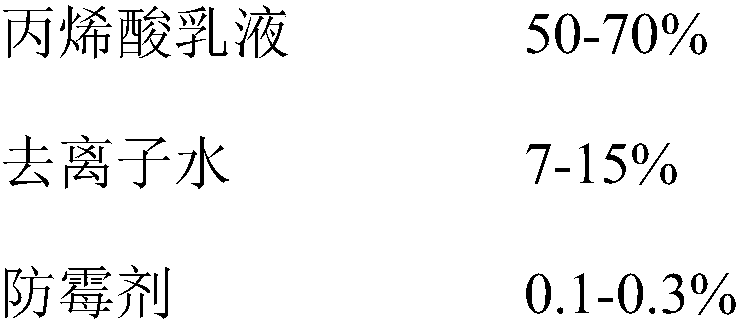

[0032] Use 700kg of acrylic emulsion for the topcoat, sti...

Embodiment 2

[0034] The difference between this example and Example 1 is that the content of each component is different. Specifically, the primer uses 200kg of deionized water, 1kg of polyether polyurethane associative rheology aid with 25% solid content, and 1.5kg of defoamer. 13 kg of lauryl alcohol fat, 1 kg of thickener.

[0035] The middle layer paint is two-component, Component A uses 65kg of water, 65kg of emulsion, 7.5kg of anti-carbonation additive, and 0.08kg of anti-fungal agent. Component B is mixed evenly with 250kg of special cement, 25kg of quartz sand, and 1kg of nano-scale silicate reinforcing agent.

[0036] The topcoat uses 350kg of acrylic emulsion, 25kg of deionized water, 1.1kg of antifungal agent, 105kg of heavy calcium powder, 18kg of film-forming aid, 7kg of antioxidant, 0.5kg of defoamer, and 0.6kg of thickener.

[0037] Based on the above, the present invention has the advantage that: the present invention uses nano-scale silicate material and organosiloxane co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com