Salt crystallization separation device and process capable of realizing zero emission

A zero-emission, crystallization technology, applied in chemical instruments and methods, water/sludge/sewage treatment, alkali metal halide purification, etc., can solve problems such as increased fouling tendency, secondary pollution, and limited application, and achieve mitigation pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

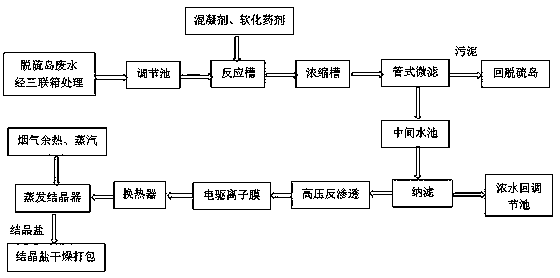

Embodiment 1

[0052] Embodiment 1 of the present invention, power plant desulfurization wastewater zero discharge process: desulfurization wastewater passes through the triple box reactor, and heavy metal ions such as Cr3+ and Hg2+ in the water are co-precipitated with Fe hydroxide in the form of hydroxide precipitation of metal ions, and the supernatant In the water adjustment tank, lime milk, sodium carbonate and liquid caustic soda are added to the reaction tank to react with calcium and magnesium ions in the water to form hydroxide and carbonate precipitation, and then the tubular membrane is used for solid-liquid separation to remove water Hardness ions, suspended solids, etc., the effluent is adjusted to neutral pH with hydrochloric acid and sent to the nanofiltration system to complete the separation of monovalent ions and divalent ions. The concentrated water from nanofiltration is returned to the adjustment tank, and the produced water from nanofiltration is concentrated into high-p...

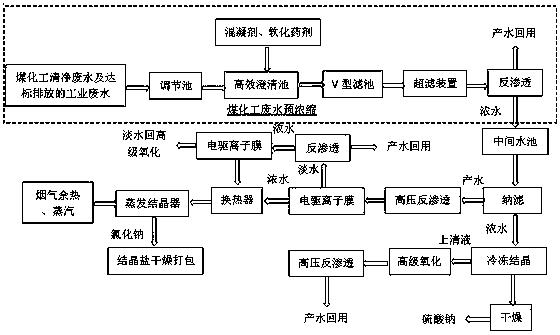

Embodiment 2

[0054] Embodiment 2 of the present invention, coal chemical industry wastewater zero-discharge process: the wastewater mainly includes the drainage of each circulating water station, the drainage of the desalinated water station, and the effluent of the coal chemical industry wastewater treatment station. Firstly, it enters the regulating tank for homogeneous mass and quantity, then enters the high-efficiency clarification tank and V-type filter tank to remove alkalinity, hardness, organic colloids and inorganic colloids with small molecular weight, and then filters through the ultrafiltration device to achieve the water inlet conditions of reverse osmosis. The ultrafiltration product water enters the reverse osmosis, the recovery rate is greater than 70%, the product water can be reused for cooling tower replenishment, and the reverse osmosis concentrated water is treated with zero discharge. The reverse osmosis concentrated water first enters the nanofiltration device for sal...

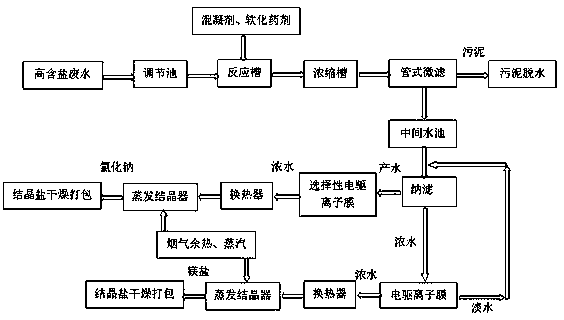

Embodiment 3

[0056] Embodiment 3 of the present invention: Recycling process of high-salt wastewater: high-salt wastewater enters the regulating tank for homogenization and equalization. In the reaction tank, medicaments such as lime milk and soda ash are added to react with calcium ions in the water to generate carbonic acid. Calcium is precipitated and the pH value is controlled to prevent carbonate hydrolysis, and then the tubular membrane is used for solid-liquid separation to remove suspended solids in the water, and the effluent is adjusted to neutral pH and enters the nanofiltration system for the separation of monovalent ions and divalent ions. The water produced by nanofiltration is concentrated by the one- and two-valent selective electric drive ion membrane, and the monovalent salt is transferred to the concentrated water side. The concentration reaches more than 20% and enters the evaporation crystallizer. The heat pump of the evaporation crystallization system uses the waste hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com