Piston rod of shock absorber and manufacturing method for piston rod

A technology of piston rod and shock absorber, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problems of low dimensional accuracy, unsatisfactory quality, high component rejection rate, and simple preparation process. Easy to operate, improve hardness, improve product density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

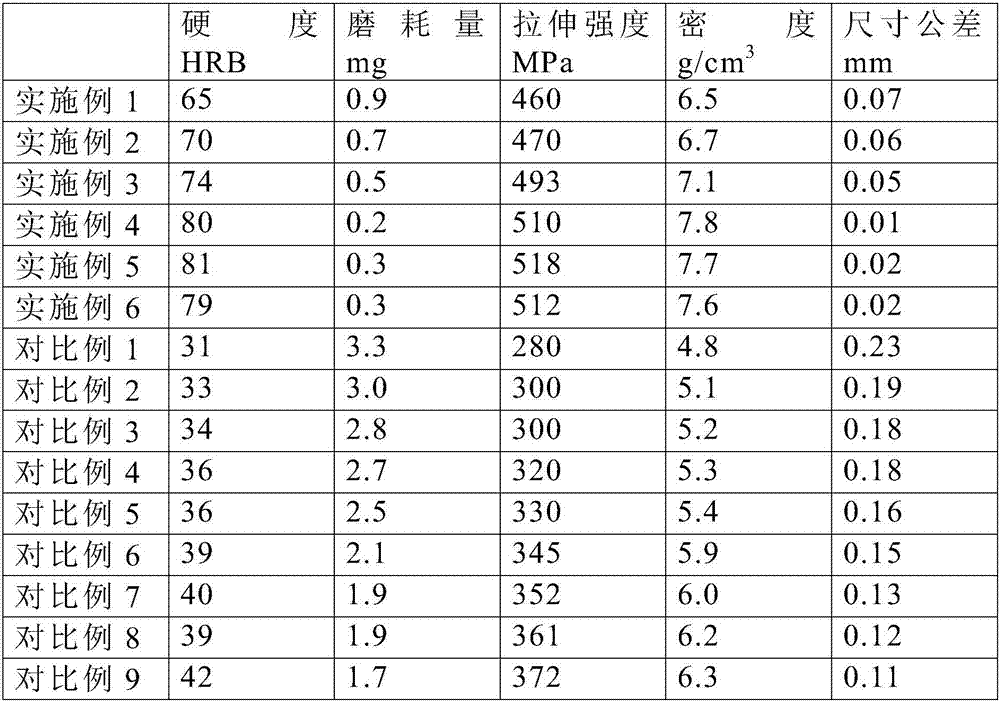

Examples

Embodiment 1

[0022] The raw material of described shock absorber piston rod comprises the component of following parts by weight:

[0023] Fe powder: 70 parts; copper composite powder: 5 parts; nickel powder: 1 part; antimony powder: 0.5 parts; yttrium oxide: 0.5 parts; hard fatty acid zinc: 0.5 parts; layer. The particle size of the Fe powder is 1 μm, the particle size of the copper powder is 1 μm, and the particle size of the nickel powder is 1 μm.

[0024] The preparation method of the copper composite powder comprises: dissolving manganese sulfate in acetone, and then adding copper powder, the mass ratio of manganese sulfate to copper powder is 0.5:1. Stir evenly to obtain a slurry, and the slurry is centrifuged at 4000r / min and spray-dried to obtain a powder. 2 , at 900°C, heated for 40 minutes to obtain copper composite powder coated with manganese.

[0025] The preparation method of the piston rod includes the following steps: weighing the raw materials according to the proportio...

Embodiment 2

[0027] The raw material of described shock absorber piston rod comprises the component of following parts by weight:

[0028] Fe powder: 70 parts; copper composite powder: 5 parts; nickel powder: 1 part; antimony powder: 0.5 parts; yttrium oxide: 0.5 parts; hard fatty acid zinc: 0.5 parts; layer. The particle diameter of the Fe powder is 500 nm, the particle diameter of the copper powder is 4 μm, and the particle diameter of the nickel powder is 1 μm.

[0029] The preparation method of the copper composite powder comprises: dissolving manganese sulfate in acetone, and then adding copper powder, the mass ratio of manganese sulfate to copper powder is 0.5:1. Stir evenly to obtain a slurry, and the slurry is centrifuged at 4000r / min and spray-dried to obtain a powder. 2 , at 900°C, heated for 40 minutes to obtain copper composite powder coated with manganese.

[0030] The preparation method of the piston rod includes the following steps: weighing the raw materials according to...

Embodiment 3

[0032] The raw material of described shock absorber piston rod comprises the component of following parts by weight:

[0033] Fe powder: 70 parts; copper composite powder: 5 parts; nickel powder: 1 part; antimony powder: 0.5 parts; lanthanum oxide: 0.5 parts; hard fatty acid zinc: 0.5 parts; layer. The particle diameter of the Fe powder is 500 nm, the particle diameter of the copper powder is 4 μm, and the particle diameter of the nickel powder is 1 μm.

[0034] The preparation method of the copper composite powder comprises: dissolving manganese sulfate in acetone, and then adding copper powder, the mass ratio of manganese sulfate to copper powder is 0.5:1. Stir evenly to obtain a slurry, and the slurry is centrifuged at 4000r / min and spray-dried to obtain a powder. 2 , at 900°C, heated for 40 minutes to obtain copper composite powder coated with manganese.

[0035] The preparation method of the piston rod includes the following steps: weighing the raw materials according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com