Fluorine-modified hydrophobic epoxy grouting material and preparation method thereof

An epoxy grouting and hydrophobic technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of low compressive strength, reduced adhesion, low hardness, etc., and achieve strong impact resistance, acid and alkali resistance Improvement, the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

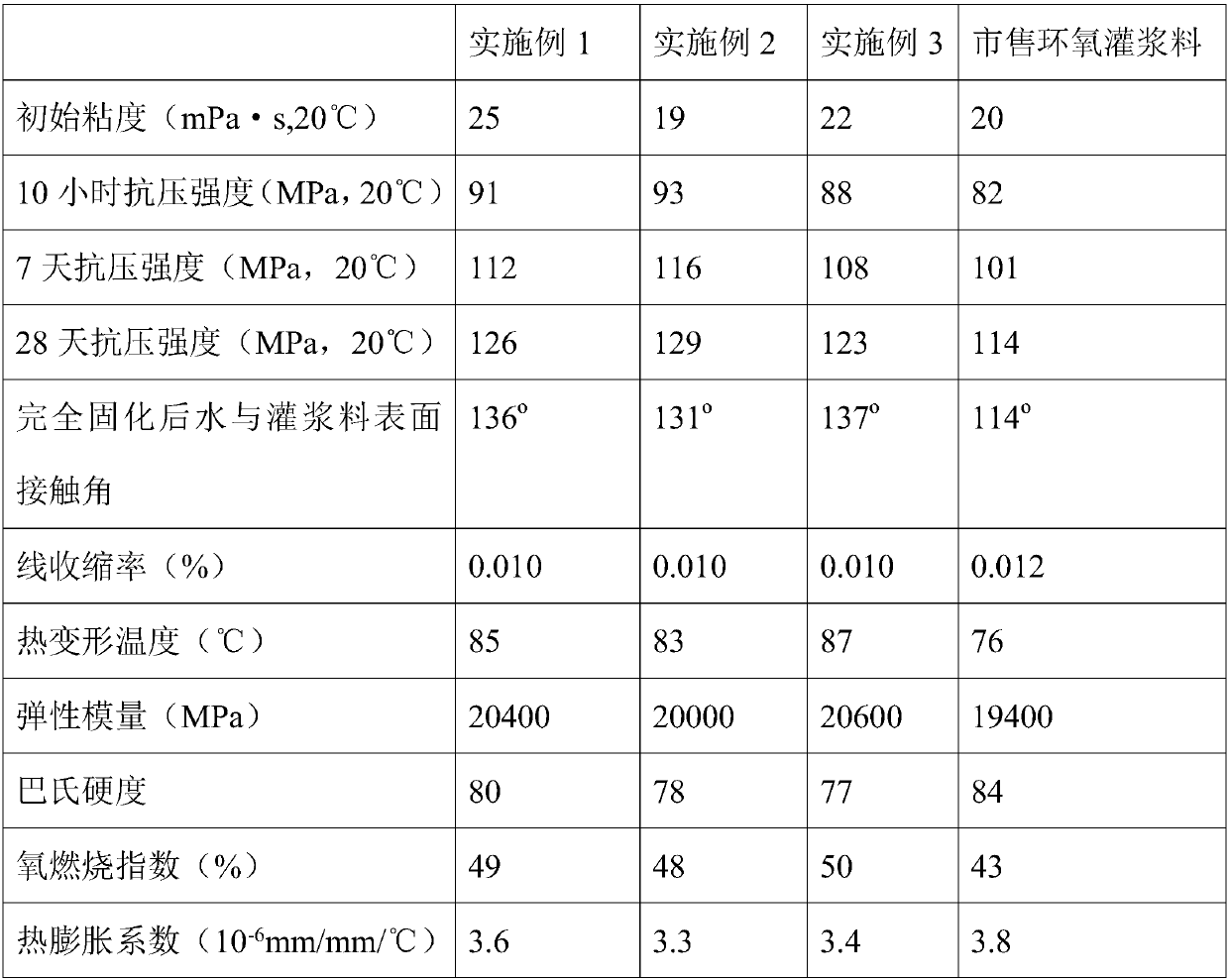

Examples

Embodiment 1

[0021] A fluorine-modified hydrophobic epoxy grout, which is a fluorine-modified hydrophobic epoxy grout modified by using Kevlar fiber as a chemical and physical reinforcing agent, a fluorine-containing coupling agent, and an organic fluorine curing agent. A and B components, wherein, in parts by mass, component A: 80 parts of bisphenol A epoxy resin, 10 parts of 1H,1H,2H,2H-heptadecafluorodecyltrimethoxysilane, 25 parts of 2 -(3,4-epoxycyclohexyl)ethyltrimethoxysilane; in parts by mass, component B: 15 parts of 2-perfluorotriethylene tetraamine phenol, 18 parts of Kevlar fiber (particle size 40~80μm, length 3mm~60mm), 10 parts of 2,4,6-tris(dimethylamino)phenol, 18 parts of benzyl alcohol, 3 parts of lead naphthenate.

Embodiment 2

[0023] A fluorine-modified hydrophobic epoxy grout, which is a fluorine-modified hydrophobic epoxy grout modified by using Kevlar fiber as a chemical and physical reinforcing agent, a fluorine-containing coupling agent, and an organic fluorine curing agent. A and B components are composed, wherein, in parts by mass, component A: 100 parts of bisphenol F epoxy resin, 20 parts of dimethyl-mono(pentafluorophenyl) propyl-monomethoxysilane, 35 parts Parts of allyl glycidyl ether; in parts by mass, component B: 20 parts of tetrafluoro-1,2-ethanedithiol, 12 parts of Kevlar fiber (diameter 30-60 μm, length 1mm-5mm), 6 parts 2,4,6-tris(dimethylamino)phenol, 12 parts of benzyl alcohol, 6 parts of dibutyltin maleate.

Embodiment 3

[0025] A fluorine-modified hydrophobic epoxy grout, which is a fluorine-modified hydrophobic epoxy grout modified by using Kevlar fiber as a chemical and physical reinforcing agent, a fluorine-containing coupling agent, and an organic fluorine curing agent. A and B components, wherein, in parts by mass, component A: 88 parts of bisphenol F epoxy resin, 16 parts of trifluoromethyltrimethoxysilane, 32 parts of 2-(3,4-epoxy Cyclohexyl)ethyltrimethoxysilane; in parts by mass, component B: 18 parts of perfluorotetraethylenepentamine, 14 parts of Kevlar fiber (80-100 μm in diameter, 5 mm-10 mm in length), 9 parts of N , N-dimethylaniline, 14 parts of benzyl alcohol, 4.5 parts of dibutyltin dilaurate.

[0026] A fluorine-modified hydrophobic epoxy grout in Examples 1-3, the preparation method is as follows:

[0027] (1) Add epoxy resin, reactive diluent, and fluorine-containing coupling agent into the dispersion tank a, stir and mix evenly, and take it out for use as component A; ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com