Design method of BFRP bar anti-floating anchor rod

A technology of anti-floating anchor rods and design methods, which is applied to sheet pile walls, protective devices, buildings, etc., can solve the problems of anti-corrosion measures increasing construction procedures and project costs, not complying with national energy-saving policies, and not having use conditions, etc., to achieve high Acid and alkali resistance, anti-corrosion, and increased compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

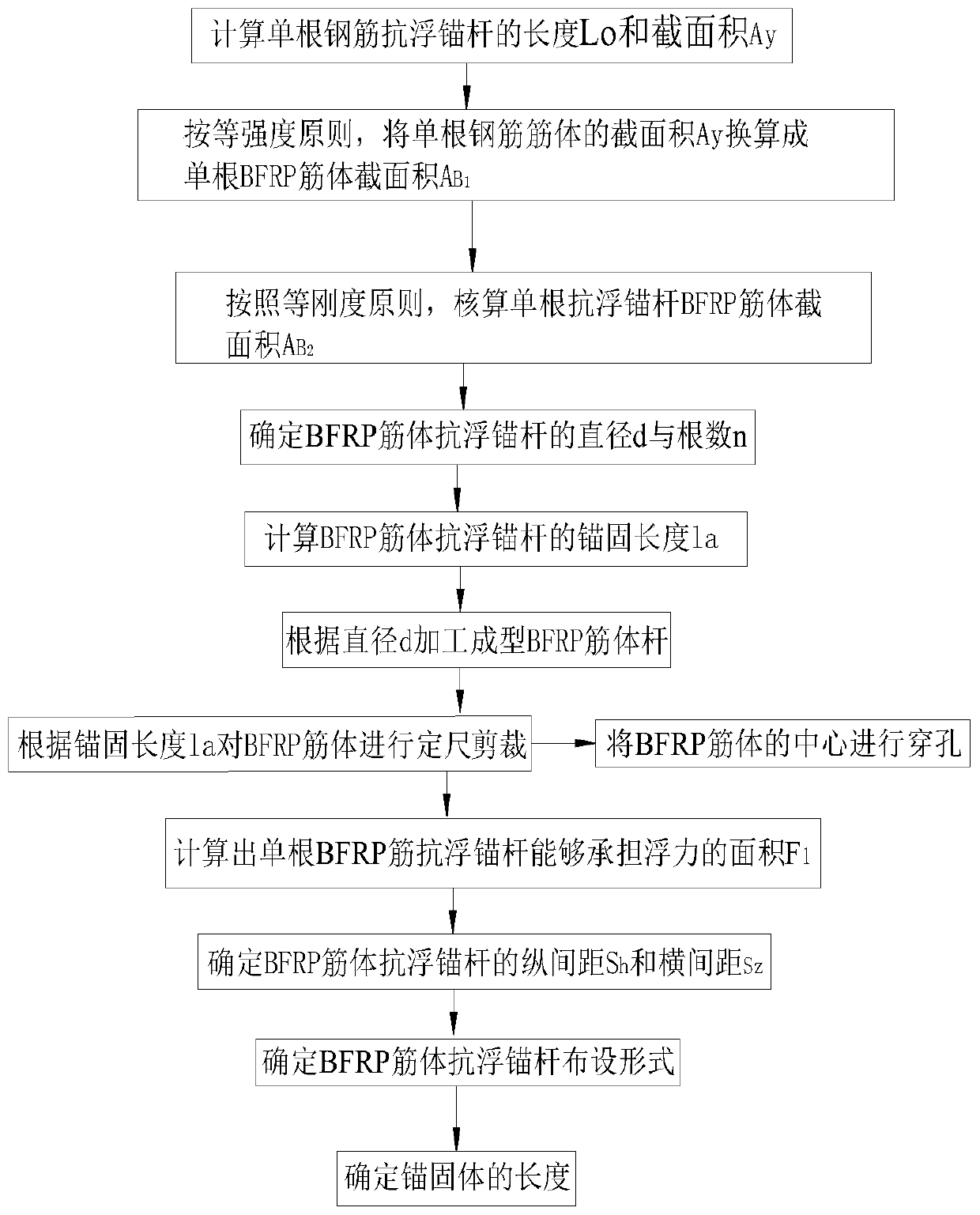

[0031] Embodiment: BFRP bar anti-floating bolt design method, such as figure 1 shown, including the following steps:

[0032] 1) Design and calculate the cross-sectional area A of a single anti-floating anchor bar using steel bars according to the current engineering technical standards y and length L 0 .

[0033] 2) According to the cross-sectional area A of a single anti-floating anchor bar reinforced bar calculated in step 1) y , according to the principle of equal strength, the cross-sectional area A of a single anti-floating anchor bar reinforcement bar y Converted to the cross-sectional area A of the anti-floating anchor rod with BFRP reinforcement B1 , namely f B A B1 = f y A y , where f B is the tensile strength of BFRP tendons, f y is the tensile strength of the steel bar.

[0034] 3) A calculated according to the principle of equal intensity in step 2) B1 , and then calculate the cross-sectional area A of a single anti-floating anchor rod BFRP reinforceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com