DdFeB magnet surface composite metal protection layer and preparing method thereof

A metal protective layer and surface composite technology, applied in the field of metal surface treatment, can solve the problems of low corrosion resistance, low hardness of the protective layer, high brittleness of the protective layer, etc., and achieve the effect of preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

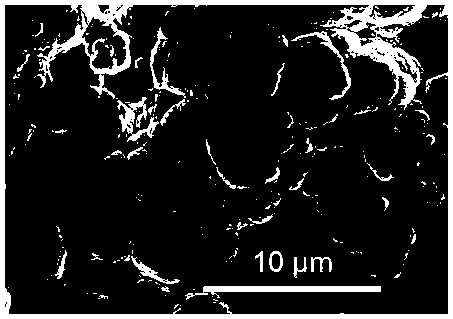

Image

Examples

Embodiment 1

[0040] Step 1) Pre-processing

[0041] Soak NdFeB in degreasing agent to remove oil, then soak in 3% dilute nitric acid to remove rust, then wash with water, alcohol and then dry. Thereafter, the NdFeB was placed in an argon-protected glove box, and the AlCl with a molar ratio of 2.0 3 -Anode activation in EMIC ionic liquid, the anode is NdFeB, the cathode is Al, and the current density is 20mA / cm 2 , the time is 10min.

[0042] Step 2) Ionic Liquid Aluminum Plating

[0043] AlCl at a molar ratio of 2.0 3 - Galvanostatic Al plating in EMIC ionic liquids. The pretreated NdFeB is used as the cathode, the pure Al is used as the anode, the bath temperature is 25°C, and the current density is 10mA / cm 2 , the plating time is 50min, and the coating thickness is 10μm.

[0044] Step 3) Ionic Liquid Plating Amorphous Al-Mn Alloy

[0045] in AlCl 3 / EMIC molar ratio is 2.0, MnCl 2 Concentration of 0.20M MnCl 2 -AlCl 3 -EMIC ionic liquids for galvanostatic plating of amorphous ...

Embodiment 2

[0050] Step 1) is the same as in Example 1.

[0051] In step 2), the plating time is 25min, and the others are the same as in Example 1.

[0052] Step 3) in, plating time is 60min, other is the same as embodiment 1.

[0053] Step 4) is the same as in Example 1.

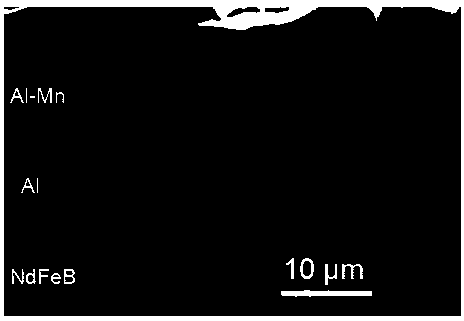

[0054] Result: if image 3 As shown, the Al coating is 5 μm, the Al-Mn alloy coating is 5 μm, and the Mn content in the alloy layer is 15.0 at.%, which is in the range of amorphous composition (as shown in Table 1). The bonding strength of the coating is greater than 20MPa, the sample has no rust after 1000h neutral salt spray test, and the thermal attenuation of magnetic properties is less than 1%.

Embodiment 3

[0056] Step 1) is the same as in Example 1.

[0057] In step 2), the bath temperature is 50°C, and the current density is 50mA / cm 2 , the plating time is 2min, and others are the same as in Example 1.

[0058] In step 3), MnCl 2 The concentration is 0.15M, the bath temperature is 50°C, and the current density is 9mA / cm 2 , the plating time is 24min, other with embodiment 1.

[0059] Step 4) is the same as in Example 1.

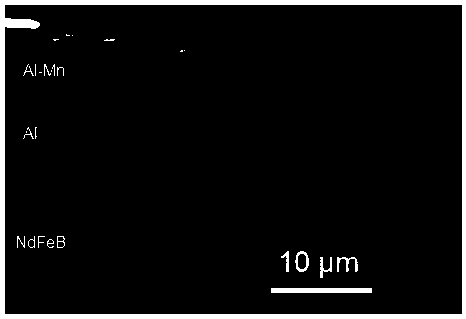

[0060] Result: if Figure 4 As shown, the Al coating is 2 μm, the Al-Mn alloy coating is 3 μm, and the Mn content in the alloy layer is 14.1 at.%, which is in the range of amorphous composition (as shown in Table 1). The bonding strength of the coating is greater than 20MPa, the sample has no rust after 500h neutral salt spray test, and the thermal attenuation of magnetic properties is less than 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com