Nylon composite material and preparation method thereof

A nylon composite material, nylon technology, used in building insulation materials, building components, buildings, etc., can solve the problems of unstable mechanical properties, inability to improve dispersibility, failure to improve dispersibility, mechanical properties and water absorption, etc. Mechanical properties, improve dispersibility, improve mechanical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The graphite fluoride mass fraction is a nylon composite material of 3%, and the specific preparation method is as follows:

[0040] (1) Nylon 6 was dried at 60°C for 12 hours, then mixed with fluorinated graphite in a rheometer, and mixed at 240°C and 50 rpm for 15 minutes to obtain the product;

[0041] (2) The product described in step (1) was pulverized, dried at 60°C for 12 hours, and injected to obtain a nylon composite material with a mass of 3% graphite fluoride.

Embodiment 2

[0043] The graphite fluoride mass fraction is a nylon composite material of 0.5%, and the specific preparation method is as follows:

[0044] (1) Nylon 6 was dried at 50°C for 13 hours, then mixed with fluorinated graphite in a rheometer, and mixed at 220°C and 80 rpm for 12 minutes to obtain the product;

[0045] (2) The product described in the step (1) was pulverized, dried at 50°C for 13 hours, and injected to obtain a nylon composite material with a mass of 0.5% graphite fluoride.

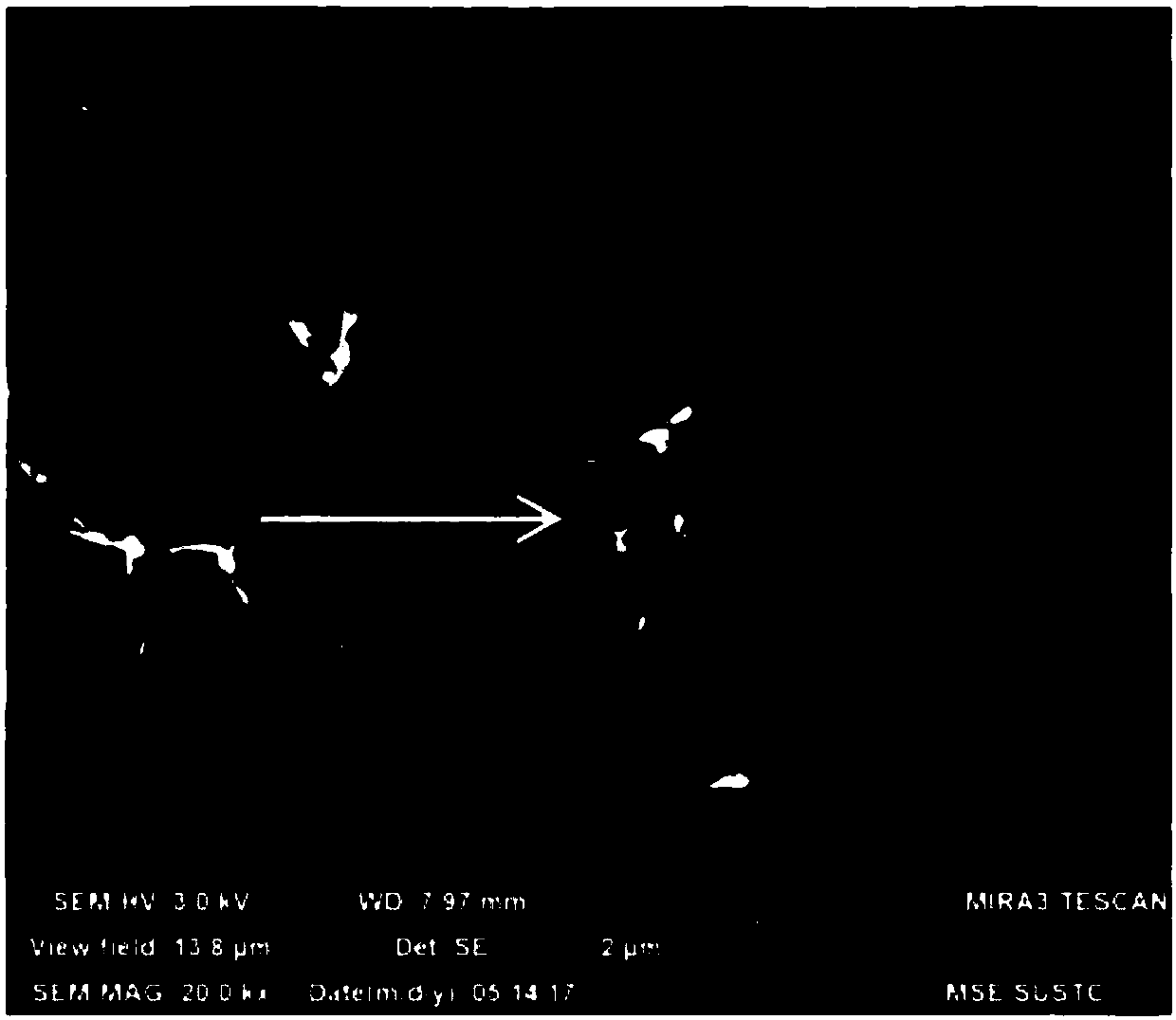

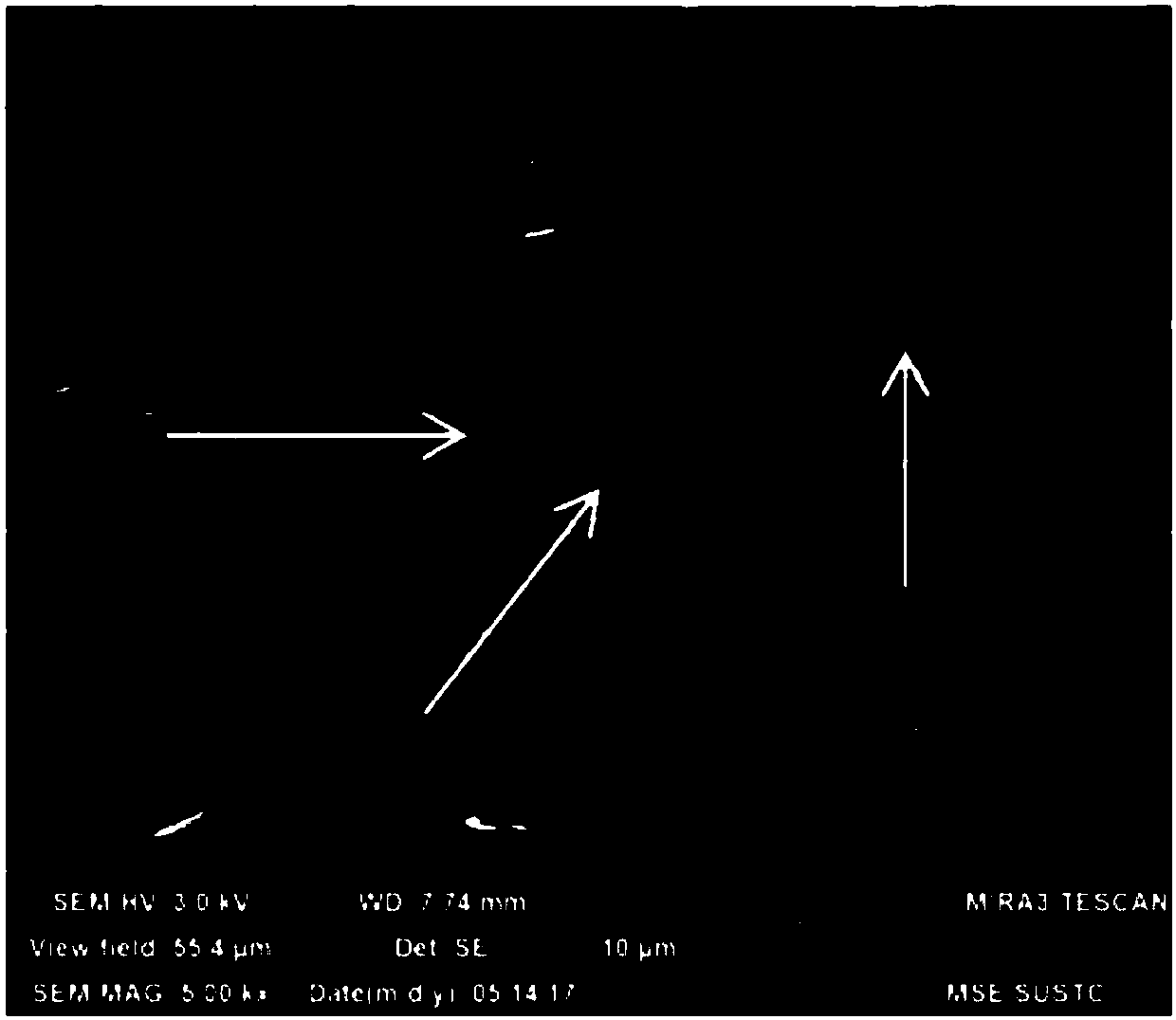

[0046] The prepared nylon composite material was subjected to scanning electron microscope analysis of liquid nitrogen brittle fracture, such as Figure 1A As shown, on the cross-sectional surface of the nylon composite material, we can see well-dispersed fluorocarbon material particles, and many wrinkles centered on it appear on the surface, indicating that the fluorocarbon material is used as a stress dispersion point, which improves the nylon composite material. The mechanical properties of...

Embodiment 3

[0048]The graphite fluoride mass fraction is a nylon composite material of 1%, and the specific preparation method is as follows:

[0049] (1) Dry nylon 6 at 70°C for 10 hours, then mix it with fluorinated graphite in a rheometer, and knead at 250°C and 40 rpm for 17 minutes to obtain the product;

[0050] (2) The product described in step (1) was pulverized, dried at 70° C. for 10 hours, and injected to obtain a nylon composite material with 1% graphite fluoride mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com