Normal-temperature curing type high-hardness coating

A room temperature curing, high hardness technology, applied in the field of coating agents and coatings, can solve the problems of difficulty in forming uniform, moldy, chalking, good gloss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

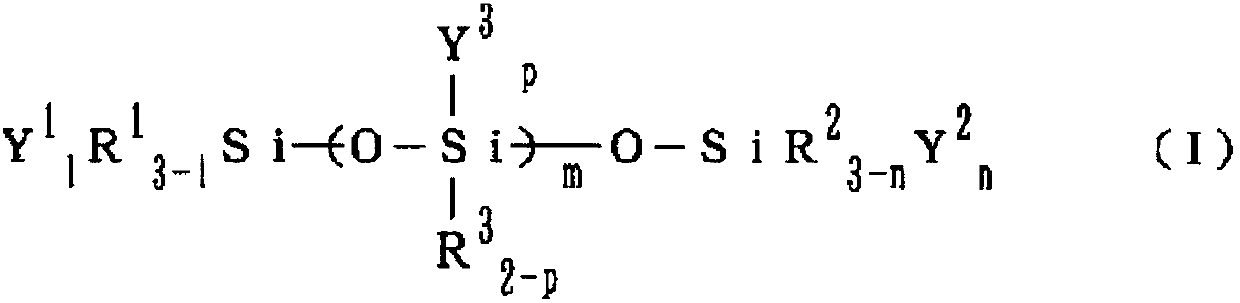

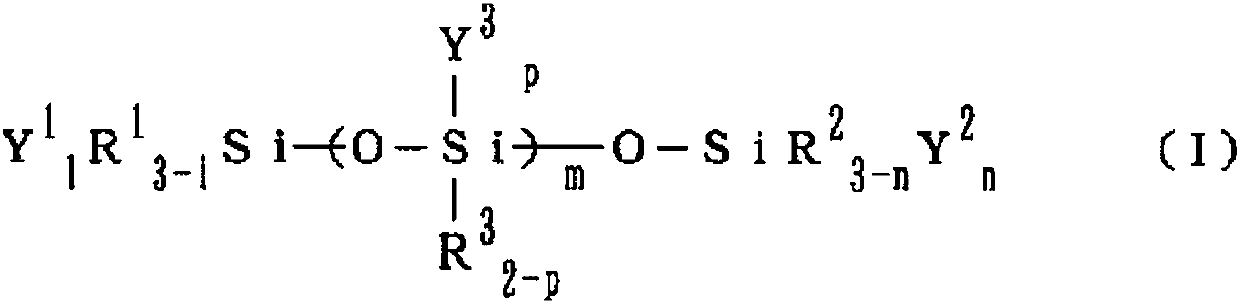

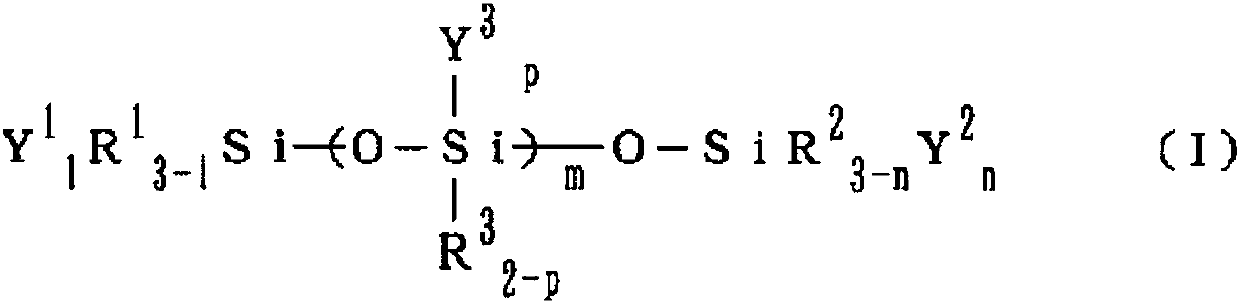

Method used

Image

Examples

Embodiment 1~15 and comparative example 1~3

[0072] A paint composition was prepared by mixing the following resin (A), a siloxane oligomer as a reactive diluent (B), and a catalyst (C) in the composition shown in Table 1. Proportions are expressed by weight. On a 0.6mm thick degreased mild steel plate (5cm*15cm) as a base material, it is coated by a bar, and dried at room temperature 25°C for 24 hours to solidify to form a dry film with a thickness of 20μm. The properties of the obtained coating films were measured by the following methods, and the results are shown in Table 1. Commercially available acrylic urethane paint, acrylic melamine paint, and polyester melamine paint were used as comparative examples.

[0073] Resin (A)

[0074] (1) Hydroxyl Fluorine Resin (A-1)

[0075] Cefral coat A-100 [manufactured by Central Glass Co., Ltd. (Central Glass Co., Ltd.)]

[0076] (Molecular weight (Mn): 3800, hydroxyl value: 50mg KOH / g)

[0077] (2) Hydroxyl-containing acrylic resin (A-2)

[0078] Alotan UW2817 [manufact...

Embodiment 16~21

[0114] Manufacture the same coating composition as the above-mentioned embodiment according to the proportioning in Table 2, and measure the performance of the coating film. The results are shown in Table 2 below.

[0115] 【Table 2】

[0116] Form 2

[0117]

[0118] Examples 16-21 of the present invention have excellent coating properties.

Embodiment 22

[0120] γ-glycidyl propyl trimethoxysilane is used as reactive diluent (B) instead of siloxane oligomer; BF3 complex is used as catalyst (C) instead of boron trifluoride monoethylamine, For the rest, the steps of Examples 16-21 were repeated to manufacture a coating composition. The performance of the coating film of the obtained coating composition of the present invention was good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com