Photosensitive polyimide resin composition

A technology of polyimide resin and resin composition, applied in the direction of photosensitive material processing, optics, optomechanical equipment, etc., can solve the problems of improving physical properties and achieve the effect of fully cross-linked structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

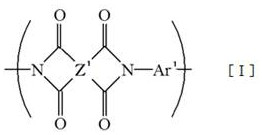

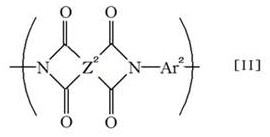

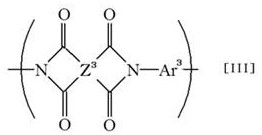

Image

Examples

preparation example Construction

[0113] Preparation method of photosensitive polyimide pattern

[0114] A photosensitive polyimide pattern can be prepared on a substrate using a photosensitive polyimide resin composition containing the above components. Specifically, the photosensitive polyimide pattern can be prepared by a method including the following steps: (1) forming a resin composition on the substrate by applying the above-mentioned photosensitive polyimide resin composition of the present invention on the substrate; (2) The process of exposing the resin layer; (3) Developing the exposed resin layer to form the insulating material of electronic parts and the passivation film, buffer coating film and interlayer in the semiconductor package A step of patterning a photosensitive polyimide such as an insulating film; and (4) a step of forming a permanent insulating film by heat-treating the photosensitive polyimide pattern.

[0115] Hereinafter, typical embodiments of each step will be described.

[011...

Embodiment 1

[0131] A stirrer, a nitrogen introduction tube, and a cooling tube equipped with a moisture receiver were attached to a glass-made detachable three-necked flask. Charge 64.45g (0.2 mol) of 3,4,3',4'-benzophenone tetracarboxylic dianhydride (hereinafter referred to as BTDA), 29.23g (0.1 mol) of 1,3-bis(3- Aminophenoxy)benzene, 1.5g (0.015 mole) of valerolactone, 2.4g (0.03 mole) of pyridine, 200g of NMP, 30g of toluene, at room temperature, under a nitrogen atmosphere, after stirring for 30 minutes at 200rpm , heated up to 180°C, heated and stirred for 1 hour. During the reaction, toluene-water azeotropic components were removed.

[0132] After cooling to room temperature, 48.33 g (0.15 moles) of BTDA, 44.57 g (0.25 moles) of 2,4-diethyl-6-methyl-1,3-phenylenediamine (relative to N- Aromatic diamine having an alkyl group), 360 g of NMP, and 90 g of toluene were stirred at room temperature for 30 minutes, then heated up to 180° C., and heated and stirred for 1 hour. While rem...

Embodiment 2

[0134] A stirrer, a nitrogen introduction tube, and a cooling tube equipped with a moisture receiver were attached to a glass-made detachable three-necked flask. Charge 64.45g (0.2 mol) of 3,4,3',4'-benzophenone tetracarboxylic dianhydride (hereinafter referred to as BTDA), 29.23g (0.1 mol) of 1,3-bis(3- Aminophenoxy)benzene, 1.5g (0.015 mole) of valerolactone, 2.4g (0.03 mole) of pyridine, 200g of NMP, 30g of toluene, at room temperature, under a nitrogen atmosphere, after stirring for 30 minutes at 200rpm , heated up to 180°C, heated and stirred for 1 hour. The toluene-water azeotropic component was removed during the reaction.

[0135] After cooling to room temperature, 48.33 g (0.15 moles) of BTDA, 51.08 g (0.25 moles) of 5,7-diamino-1,1,4,6-tetramethylindan (relative to N- Aromatic diamine having an alkyl group), 360 g of NMP, and 90 g of toluene were stirred at room temperature for 30 minutes, then heated up to 180° C., and heated and stirred for 1 hour. While removin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com