Machining method of remelted-layer removed gas film hole for aero-engine turbine blade

A technology of aero-engine and turbine blades, which is applied in the field of aero-engines, can solve problems such as the surface integrity of shadow blades, the performance of blade materials, and the decrease in safety service life, so as to control remelting layers and microcracks, reduce thermal effects, and reduce remelting layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the present invention are clearly and completely described below in conjunction with the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0028] A method for processing air film holes in a remelted layer of an aeroengine turbine blade, comprising the following steps:

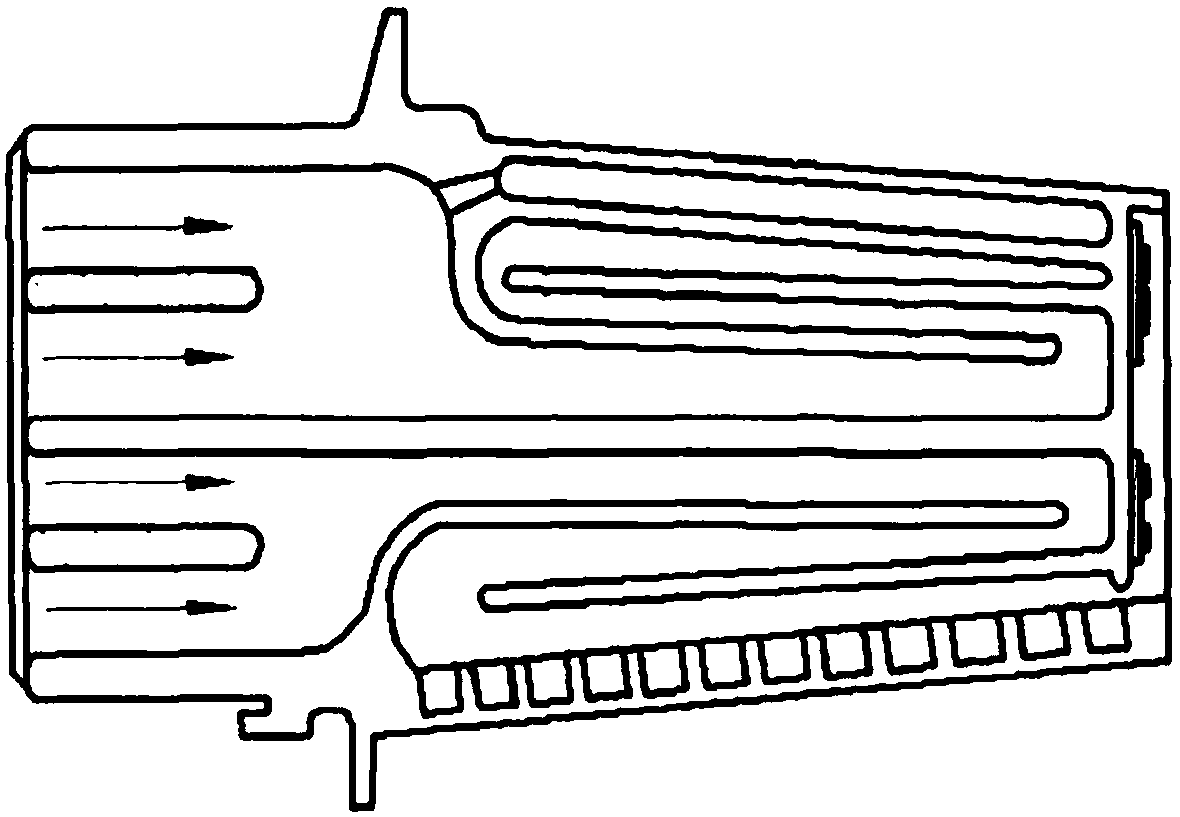

[0029] Step 1: The turbine blade is made of directional high-temperature casting alloy, and the blade body is precision cast without margin. Composite cooling structure of edge air film cooling, turbine blade cooling channels such as figure 1 , the cooling air is divided into two paths from the bottom of the tenon of the blade and enters the inner cavity of the blade, and then is discharged from the air film hole at the leading edge of the blade and the exhaust slot at the trailing edge of the blade thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com