Method for manufacturing titanium and titanium alloy and part thereof by taking hydrogenated sponge titanium as raw material

A technology of sponge titanium and raw materials, applied in the field of manufacturing powder metallurgy titanium and titanium alloys and their parts, can solve the problems of insufficient room temperature elongation, high oxygen content, long production cycle, etc., and achieve short-process manufacturing and powder quality. High, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The concrete technological process of the present embodiment is:

[0043] ①Hydrogenation of sponge titanium: In a hydrogenation furnace, keep titanium sponge with a particle size of less than 30mm at 450°C and a hydrogen pressure of 1.0 to 1.2atm for 2 hours to prepare hydrogenated titanium sponge (with a hydrogen content of 4.3wt.%) );

[0044] ② Synchronous mechanical ball milling to prepare titanium hydride powder: Under the protection of argon, put the hydrogenated sponge titanium raw material into the ball mill tank of a planetary ball mill or agitator ball mill, and perform mechanical ball milling simultaneously to prepare titanium hydride powder. Among them, under the conditions of ball-to-material mass ratio of 2.5:1 and ball mill speed of 300rpm, titanium hydride powder with a particle size of less than 25 μm can be prepared by ball milling for 30 minutes, and titanium hydride powder with a particle size of less than 15 μm can be prepared by ball milling for 1 ...

Embodiment 2

[0052] The concrete technological process of the present embodiment is:

[0053] ①Hydrogenation of sponge titanium: In a hydrogenation furnace, keep zero-grade sponge titanium at 450°C and 1.0-1.2atm hydrogen pressure for 2 hours to prepare hydrogenated titanium sponge (hydrogen content: 4.3wt.%);

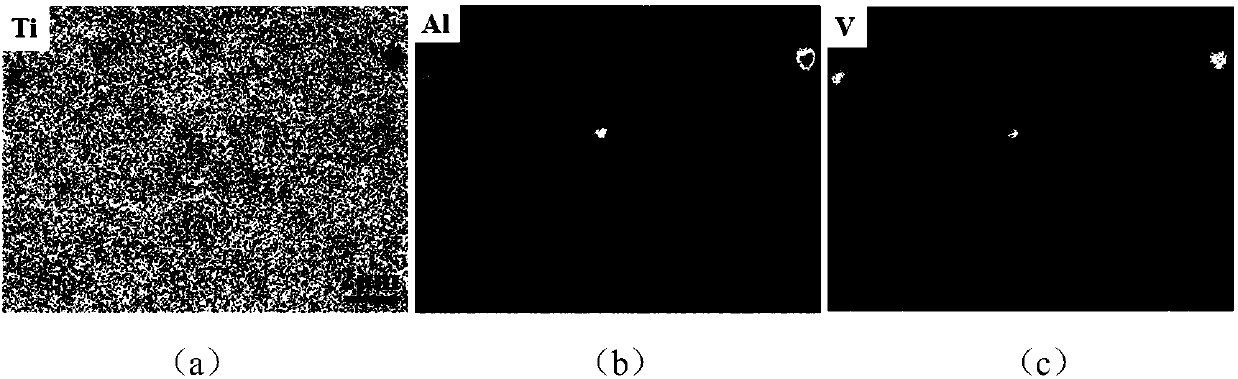

[0054] ② Synchronous mechanical ball milling to prepare alloy mixed powder: according to the mass ratio of TC4 titanium alloy Ti-6Al-4V, hydrogenated sponge titanium and brittle AlV40 intermediate alloy particles are put into the ball milling tank of the stirring ball mill together, under the protection of argon The mixed powder of titanium hydride and AlV40 was prepared by synchronous mechanical ball milling and homogenization. Among them, the mass ratio of the ball to the material is 2.4:1, the speed of the ball mill is 300rpm, and the ball mill is 2h. The particle size of the prepared mixed powder is less than 15 μm, and the average particle size is less than 4 μm; no sieving an...

Embodiment 3

[0062] The difference between this embodiment and embodiment 2 lies in the process steps ③~⑦.

[0063] The powder compact in the process step ③ is to take the powder mixture prepared by mechanical ball milling, put it into the mold cavity of the engine connecting rod part, and hold the pressure for 2 minutes under the pressure of the 950MPa hydraulic press to complete the compaction. The profile size of the control engine connecting rod powder blank is about 12% larger than the actual part size. This actually takes into account the volume shrinkage of the green compact of about 8% due to hydrogen release during the induction heating process and the subsequent machining allowance of about 4%.

[0064] Rapid sintering and simultaneous partial dehydrogenation of powder compacts in process step ④: heating the powder compacts of connecting rods at a rate of 80°C / min to 1250° C. and holding for 2 minutes; during the sintering process, the hydrogen content in the powder blank was re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com