A kind of biaxially stretched breathable film

A biaxially stretched, breathable film technology, applied to other household appliances, flat products, household appliances, etc., can solve the problems of large vertical and horizontal mechanical properties difference, large thickness of breathable film, low hydrostatic pressure, etc., to achieve vertical and horizontal mechanical properties balance , Small melt index, good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

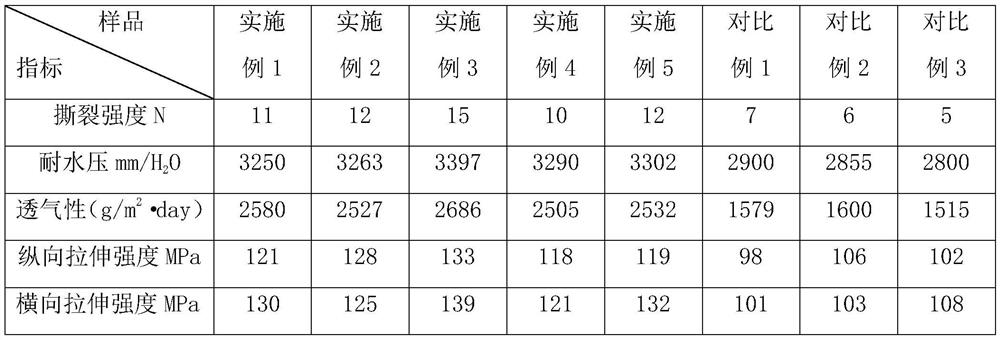

Examples

Embodiment 1

[0029] The biaxially stretched gas permeable film of this embodiment is made of the following raw materials in parts by weight: 30 parts of polyethylene, 20 parts of superfine calcium carbonate powder, 10 parts of antibacterial masterbatch, 1 part of simethicone rheological agent, 12 parts 3 parts of alkylamine polyoxyethylene ether dispersant.

[0030] Among them, polyethylene has a melt index of 0.1-2g / 10min at a temperature of 190°C and a load of 2.16kg, and a molecular weight distribution of 2-8; polyethylene is a mixture of low-density polyethylene and linear low-density polyethylene at a weight ratio of 1:3.0 to make. Ultrafine calcium carbonate powder is ultrafine calcium carbonate treated with resin acid. The particle size of the ultrafine calcium carbonate powder is 50 microns. The powder purity of the ultrafine calcium carbonate powder is 98.5%, and the whiteness is 96.5%.

[0031] The antibacterial masterbatch is made of the following components by weight: 22 par...

Embodiment 2

[0041] The biaxially stretched gas permeable film of this embodiment is made of the following raw materials in parts by weight: 60 parts of polyethylene, 35 parts of ultrafine calcium carbonate powder, 18 parts of antibacterial masterbatch, 6 parts of polymer polysiloxane rheological agent, 7 parts of stearic monoanhydride dispersant.

[0042] Among them, polyethylene has a melt index of 0.1-2g / 10min and a molecular weight distribution of 2-8 at a temperature of 190°C and a load of 2.16kg. The polyethylene is obtained by mixing low-density polyethylene and linear low-density polyethylene at a weight ratio of 1:3.5. Ultrafine calcium carbonate powder is ultrafine calcium carbonate treated with resin acid. The particle diameter of the ultrafine calcium carbonate powder is 100 microns; the powder purity of the ultrafine calcium carbonate powder is 99.5%, and the whiteness is 98%. The antibacterial masterbatch is made of the following components by weight: 30 parts of phenolic a...

Embodiment 3

[0052] The biaxially stretched gas permeable film of this embodiment is made of the following raw materials in parts by weight: 45 parts of polyethylene, 28 parts of superfine calcium carbonate powder, 14 parts of antibacterial masterbatch, 3 parts of low molecular polyamide resin rheology agent, 5 parts of bisstearamide dispersant.

[0053] Among them, polyethylene has a melt index of 0.1-2g / 10min at a temperature of 190°C and a load of 2.16kg, and a molecular weight distribution of 2-8; polyethylene is a mixture of low-density polyethylene and linear low-density polyethylene at a weight ratio of 1:3.0 into; the ultrafine calcium carbonate powder is the ultrafine calcium carbonate after resin acid treatment; the particle diameter of the ultrafine calcium carbonate powder is 60 microns; the powder purity of the ultrafine calcium carbonate powder is 99%, The whiteness is 97; the antibacterial masterbatch is made of the following components by weight: 26 parts of imidazole antib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com