A kind of recycled concrete mixed with rubber particles and its preparation method and application

A technology of recycled concrete and rubber particles, which is applied in the field of recycled concrete mixed with rubber particles and its preparation, can solve the durability of impermeability, frost resistance, carbonization resistance, shrinkage, creep and chloride ion permeability resistance. The problems of low performance, large porosity of recycled aggregates, and low output can reduce various stresses and constrain micro-cracks, improve damping performance and impact resistance, reduce crack generation and prevent or reduce cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

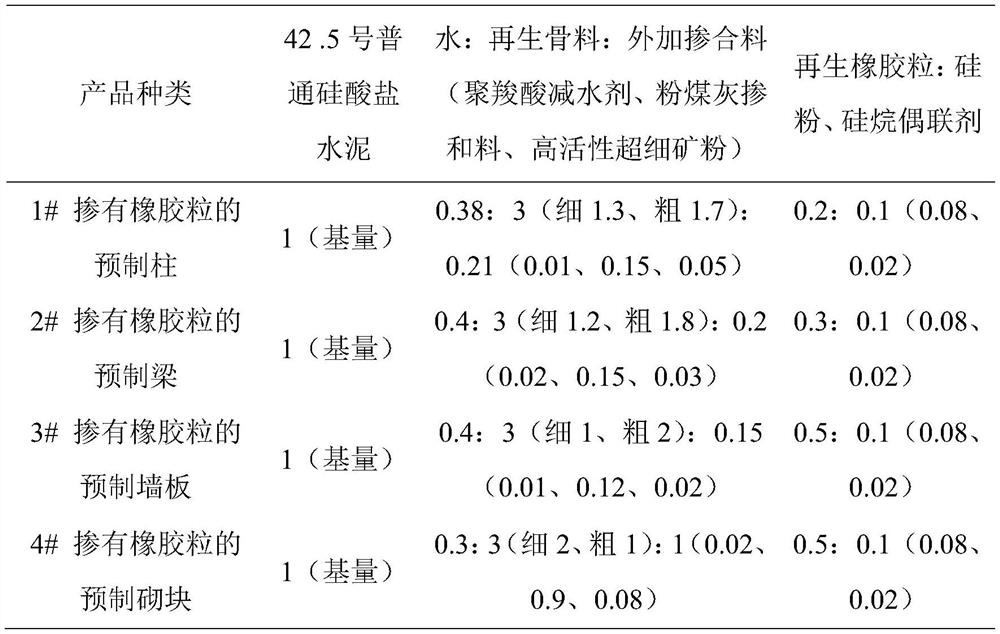

Examples

Embodiment

[0054] 1. Raw material preparation and selection

[0055] 1.1 Preparation of recycled aggregate

[0056] In the construction waste produced by building demolition and new construction, the components are very complex and the composition changes greatly, so if other impurities are mixed in the waste concrete, it will affect the performance of the recycled rubber cement concrete and its products in the later stage; and Considering that aggregates of different particle sizes are required in the preparation of recycled concrete mixed with rubber particles, it is also necessary to make up for the small cracks inside the recycled aggregate, and remove the hardened cement mortar attached to the surface of the recycled aggregate with low strength. Therefore, the preparation process of recycled aggregate is as follows: disinfection → primary screening → primary crushing → impurity removal → secondary crushing → intensive treatment → secondary screening → (regenerated aggregate) storage...

experiment example

[0086] The preparation method is the same as the example, the recycled aggregates are all from the waste concrete with the original strength of C30, the only difference is that the recycled rubber particles are no longer subjected to pretreatment, temperature-changing fluid treatment and strengthening treatment; 5# mixed with rubber granules, 6# prefabricated beams mixed with rubber granules, 7# prefabricated wallboards mixed with rubber granules, 8# prefabricated blocks mixed with rubber granules;

[0087] Among them, the compressive strength of the 1# prefabricated column mixed with rubber particles is 34.9Mpa, and the elastic modulus is 33.22KN / mm 2 ; The compressive strength of the 5# prefabricated column mixed with rubber particles is 28.6Mpa, and the elastic modulus is 27.43KN / mm2 .

[0088] 2# The compressive strength of the prefabricated beam mixed with rubber particles is 33.5Mpa, and the elastic modulus is 34.43KN / mm 2 ; 6# The compressive strength of the prefabrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com