Polycrystal hard alloy material with high strength and ductility and high abrasive resistance

A technology of cemented carbide and wear resistance, applied in the field of cemented carbide, can solve the problems of high hardness, high wear resistance and high toughness, small mean free path of Co phase, low fission resistance, etc., and achieve excellent The effect of mechanical properties, uniform distribution, and excellent hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

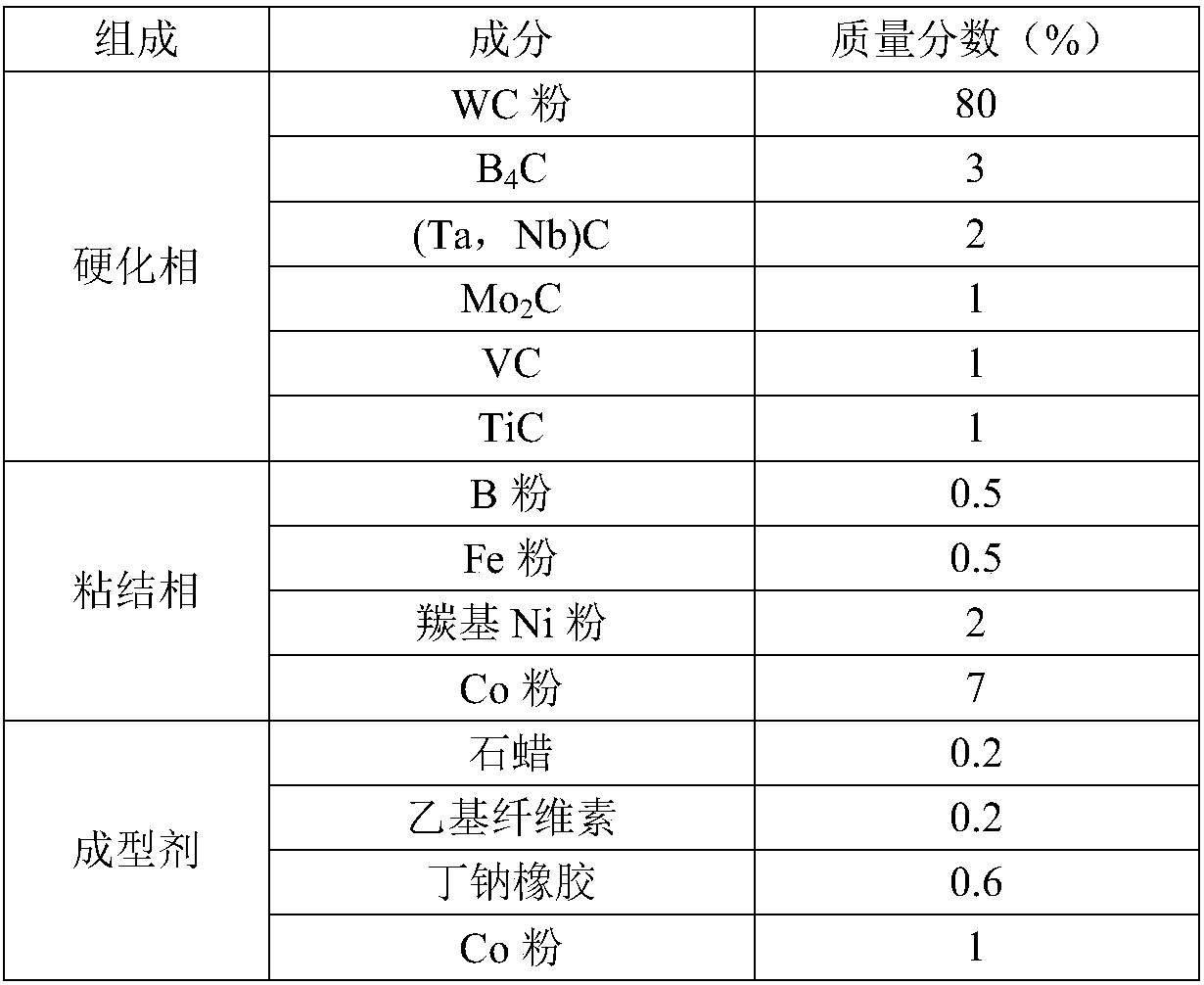

[0016] A polycrystalline cemented carbide material with high strength, toughness and high wear resistance. The cemented carbide material is composed of a hardening phase, a binding phase and a forming agent. In terms of mass fraction, the hardening phase is 88%, the binding phase is 10%, and the forming The dosage is 2%, as shown in Table 1.

[0017] Table 1:

[0018]

[0019] The hard alloy material is obtained through the following process, weighing the hardening phase, binder phase and molding agent, and uniformly mixing them to form a mixture, then pressing the mixture under a pressure of 480MPa to obtain a green compact, and then pressing the The billet is at a temperature of 1500°C and a vacuum degree of less than 1×10 -3 Sinter under the condition of Pa for 2 hours, then place it under Ar atmosphere at 1400°C and 110MPa for 2 hours, and then cool naturally to room temperature.

Embodiment 2

[0021] On the basis of the formula of Example 1, the cemented carbide material is obtained through the following process, weighing the hardening phase, binder phase and molding agent, and uniformly mixing it to form a mixture, and then mixing the mixture under a pressure of 500MPa Press molding to obtain compacts, and then press the compacts at a temperature of 1520°C and a vacuum degree of less than 1×10 -3 Sintering under the condition of Pa for 1 hour, then sintering under Ar atmosphere at 1350°C and 120MPa for 2 hours, and then naturally cooling to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com