Agar degrading enzyme generation Bacillus sp.W2017 and application thereof

A bacillus and enzyme-degrading technology, applied in the field of microorganisms, can solve problems such as inhomogeneous products, low oligosaccharide production, and difficult separation, and achieve the effects of simple nutritional requirements, short fermentation time, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] One embodiment of the preparation method of easy-soluble agar, the above-mentioned agar degrading enzyme is added to the agar substrate containing 0.2-1.0% mass volume ratio, at a temperature of 30-45 ° C, 150-200r / min The soluble agar can be prepared by enzymatic hydrolysis on a shaking table for 12-24 hours.

[0040] One embodiment is used to screen the above-mentioned Bacillus sp.W2017 fermentation to produce agar-degrading enzyme medium, wherein the carbon source in the medium contains agar.

[0041] In one embodiment, the agar is extracted from red algae. Specifically, in one embodiment, the red algae may be Asparagus or Geliflower.

[0042]In one embodiment, metal ions are added to the medium, and the weight and volume percentage of metal ions added is 0.2%-1%. Specifically, in one embodiment, the culture medium is added with Fe 2+ Ions are preferably added at a concentration of 0.2% (w / v).

[0043] In one embodiment, the above-mentioned Bacillus sp.W2017 can ...

Embodiment 1

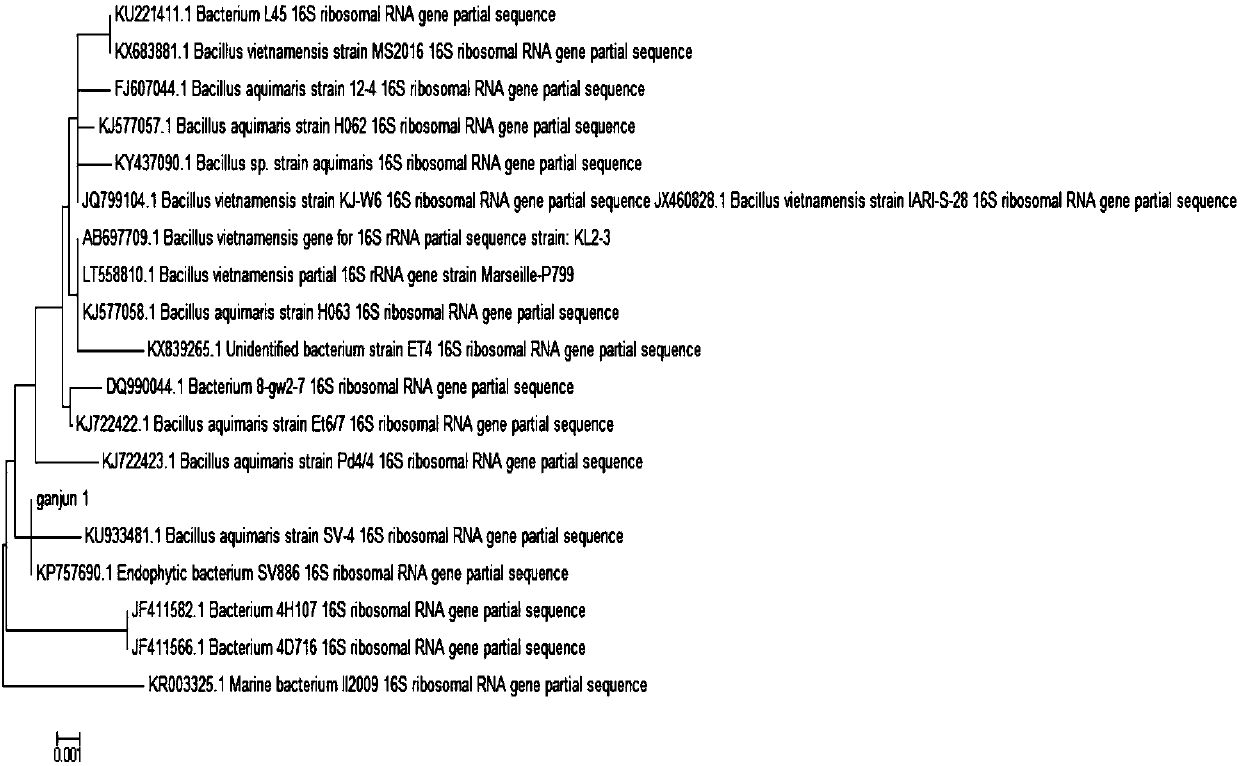

[0046] 1. Screening of Bacillus sp.W2017:

[0047] (1) Enrichment culture: pick asparagus and rot in water for 14 days.

[0048] (2) Separation and purification: spread the cultivated bacterial liquid on solid medium according to the dilution coating plate method, and select single colonies that form obvious dissolution circles on the agar plate after culturing at 37°C for 48 hours, and use conventional microbial isolation Methods The isolation and purification were repeated until the pure bacteria, namely Bacillus sp.W2017, were obtained.

[0049] The components and proportions of the solid medium used in the above enrichment and separation process are as follows:

[0050] Solid medium: tryptone 5.0g, yeast extract powder 1.0g, ferric citrate 0.02g, agar 20.0g, dilute to 1000mL with seawater.

[0051] The colony of Bacillus sp.W2017 on the solid medium is moist and smooth, with neat edges and round shape. After 48 hours of culture, a clear dissolution circle can be formed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com