Metal adhesive

A technology of metal bonding and polyether epoxy resin, applied in adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the problem of affecting product appearance and subsequent processing, clamping and fixing Complicated, low bond strength and other problems, to achieve the effect of easy industrial production, good shear strength and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

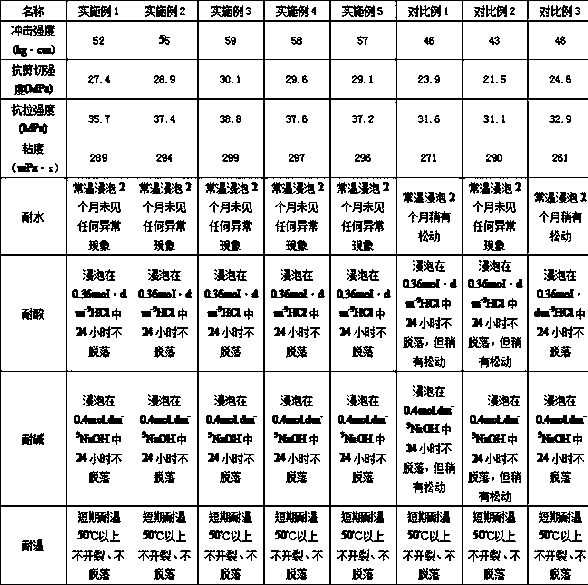

Examples

Embodiment 1

[0015] A kind of metal bonding agent comprises by weight: 40 parts of branched polyether epoxy resins, 20 parts of acrylic acid-itaconic acid copolymers, 10 parts of dibutyl maleate, 10 parts of polyamide 66, 5 parts of methyltrimethoxysilane, 5 parts of ethyl silicate, 5 parts of p-hydroxybenzenesulfonic acid, 5 parts of polyitaconic acid, 5 parts of polycrotonic acid, 3 parts of polysodium maleate, 5 parts of sodium silicate , 3 parts of cobalt boroacylate, 5 parts of polyanionic cellulose, 2 parts of nano-alumina, 2 parts of polyacrylic acid triethanolamine, 2 parts of silicon carbide whiskers, 10 parts of ethanol, 2 parts of dilute hydrochloric acid, and 20 parts of water.

[0016] The preparation method of above-mentioned metal binder is:

[0017] Step 1: Stir methyltrimethoxysilane, ethyl silicate, sodium silicate and ethanol at 75°C, slowly add the above mixed solution of dilute hydrochloric acid and water until the solution is clarified;

[0018] Step 2: Add polyamide...

Embodiment 2

[0021] A kind of metal bonding agent comprises by weight: 45 parts of branched polyether epoxy resins, 25 parts of acrylic acid-itaconic acid copolymers, 13 parts of dibutyl maleate, 15 parts of polyamide 66, 6 parts of methyltrimethoxysilane, 7 parts of ethyl silicate, 6 parts of p-hydroxybenzenesulfonic acid, 6 parts of polyitaconic acid, 6 parts of polycrotonic acid, 4 parts of polysodium maleate, 6 parts of sodium silicate , 4 parts of cobalt boroacylate, 6 parts of polyanionic cellulose, 3 parts of nano-alumina, 3 parts of polyacrylic acid triethanolamine, 4 parts of silicon carbide whiskers, 12 parts of ethanol, 3 parts of dilute hydrochloric acid, and 25 parts of water.

[0022] The preparation method of above-mentioned metal binder is:

[0023] Step 1: Stir methyltrimethoxysilane, ethyl silicate, sodium silicate and ethanol at 75°C, slowly add the above mixed solution of dilute hydrochloric acid and water until the solution is clarified;

[0024] Step 2: Add polyamide...

Embodiment 3

[0027] A kind of metal bonding agent comprises by weight: 50 parts of branched polyether epoxy resins, 25 parts of acrylic acid-itaconic acid copolymers, 15 parts of dibutyl maleate, 15 parts of polyamide 66, 7.5 parts of methyltrimethoxysilane, 7.5 parts of ethyl silicate, 7.5 parts of p-hydroxybenzenesulfonic acid, 7.5 parts of polyitaconic acid, 7 parts of polycrotonic acid, 5 parts of polysodium maleate, 7 parts of sodium silicate , 5 parts of cobalt boroacylate, 6 parts of polyanionic cellulose, 3 parts of nano-alumina, 4 parts of polyacrylic acid triethanolamine, 5 parts of silicon carbide whiskers, 15 parts of ethanol, 4 parts of dilute hydrochloric acid, and 30 parts of water.

[0028] The preparation method of above-mentioned metal binder is:

[0029] Step 1: Stir methyltrimethoxysilane, ethyl silicate, sodium silicate and ethanol at 80°C, slowly add the above mixed solution of dilute hydrochloric acid and water, and wait until the solution is clarified;

[0030] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com