Damping coating forming multi-layer compound structure

A damping coating, multi-layer composite technology, applied in the field of damping coatings, can solve the problems affecting the life of the hull and structural safety, long drying time, large smoke generation, etc., to reduce ship vibration and noise, excellent mechanical properties, and damping temperature. field width effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

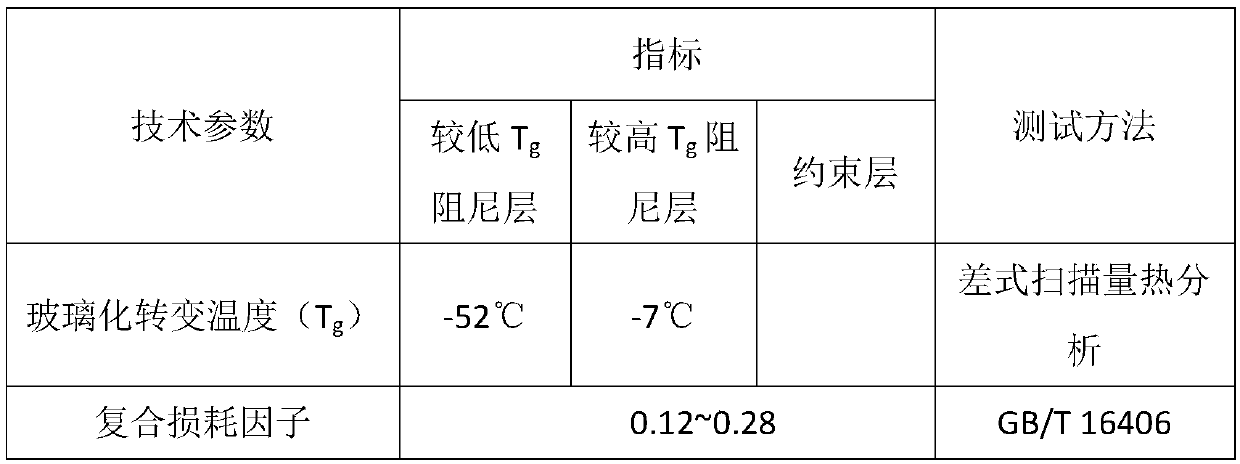

Embodiment 1

[0037] Get 100 grams of polyether with an equivalent weight of 1000, 17.4 grams of toluene diisocyanate, add 4.5 grams of 1,4-butanediol after the reaction, 10 grams of tris (2-chloroethyl) phosphate, 120 grams of 200 mesh mica powder, mix Evenly coated on the substrate, the layer is lower T gDamping paint layer; get equivalent is 400 polyether 40 grams, polyether 100 grams that equivalent is 1000, diphenylmethane diisocyanate 100 grams, add 1,6-hexanediol 35 grams after reaction, three (2-chloro Ethyl) phosphoric acid ester 50 grams, 200 mesh mica powder 300 grams, after mixing evenly, be coated on lower T g The upper layer of the damping paint layer, which is the higher T g Damping coating layer: take 100 grams of E-44 epoxy resin, 40 grams of curing agent with an amine value of 300, 100 grams of aluminum hydroxide, 40 grams of talcum powder, 6 grams of glycidyl ether reactive diluent, and 3 grams of polyamide wax , 1 gram of organic chromium complex coupling agent, 0.5 gr...

Embodiment 2

[0039] Get the polyether 90 grams that the equivalent weight is 900, diphenylmethane diisocyanate 25 grams, add neopentyl glycol 5.2 grams after the reaction, tris (2-chloroisopropyl) phosphate 8 grams, 130 grams of 100 order graphites, mix Evenly coated on the substrate, the layer is lower T g Damping paint layer: get 120 grams of polyether with an equivalent weight of 600, 60 grams of polyether with an equivalent weight of 1200, and 135 grams of polyphenyl polymethylene diisocyanate, add 3,5-dimethylthiotoluenediamine 80 after the reaction gram, 58 grams of three (2-chloroisopropyl) phosphate esters, 320 grams of 100 mesh graphites, mix uniformly and coat at lower T g The upper layer of the damping paint layer, which is the higher T g Damping paint layer: get 100 grams of E-44 epoxy resin, 38 grams of curing agent with an amine value of 350, 150 grams of antimony trioxide, 50 grams of glass fiber, 7 grams of glycidyl ether reactive diluent, and gas-phase white carbon 2 gra...

Embodiment 3

[0041] Get the polyether 80 grams that equivalent weight is 800, polyphenyl polymethylene diisocyanate 26 grams, add 1,4-cyclohexanediol 5.9 grams, three (2-chloroisopropyl) phosphoric acid ester 5 grams after reaction, 130 grams of 160 mesh vermiculite powder, mixed evenly and coated on the substrate, this layer is a lower T g Damping coating layer: take 120 grams of polyether with an equivalent weight of 600, 60 grams of polyether with an equivalent weight of 1200, and 87 grams of toluene diisocyanate, add 3,3'-dichloro-4,4'-diaminodiphenylmethane after the reaction 100 grams, 20 grams of tris (2-chloroisopropyl) phosphate, 400 grams of 160 mesh vermiculite powder, mix evenly and apply on lower T g The upper layer of the damping paint layer, which is the higher T g Damping coating layer: Take 100 grams of E-51 epoxy resin, 35 grams of curing agent with an amine value of 380, 150 grams of expandable graphite, 56 grams of titanium dioxide, 5 grams of glycidyl ester reactive d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com