Water-based damping coating as well as preparation method and application thereof

A damping coating, water-based technology, applied in the field of damping coatings, can solve the problems of low sound absorption and noise reduction effect, damping factor, that is, the decline of shock absorption and noise reduction effect, etc., to achieve good sound absorption and noise reduction effect, good application potential, and good appearance Effects and Effects of Using Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0060] This preparation example provides a kind of pure acrylic emulsion, the preparation method of described pure acrylic emulsion comprises the following steps: take 45 parts of deionized water and 30 parts of butyl acrylate (BA), 20 parts of methyl acrylate (MMA), 3 parts of acrylic acid (AA), 3 parts of nonylphenol polyoxyethylene ether (OP-10), 1.5 parts of sodium dodecyl sulfate (SDS), added to the emulsification container, stirred at room temperature, stirred evenly after 2 hours, and obtained a pre-emulsion . Then add 0.6 parts of sodium bicarbonate, heat to 50°C in a water bath, continue stirring for 1.5 hours, control the temperature at 50-55°C, and slowly add 0.6 parts of potassium persulfate dropwise to make a milky white mixture, cool to 40°C, adjust with ammonia water pH = 8 to 9, to prepare pure acrylic emulsion for use.

preparation example 2

[0062] This preparation example provides a kind of styrene-acrylic emulsion, the preparation method of described styrene-acrylic emulsion comprises the following steps: take 50 parts of deionized water and 15 parts of styrene (SA), 15 parts of butyl acrylate (BA), 5 parts of methyl Add methyl acrylate (MMA), 3 parts of acrylic acid (AA), 1.5 parts of nonylphenol polyoxyethylene ether (OP-10), 3 parts of sodium dodecyl sulfate (SDS), into the emulsification container, and stir at room temperature , Stir evenly after 1.5h to obtain a pre-emulsion. Then add 0.6 parts of sodium bicarbonate, heat it in a water bath to 75°C, continue to stir for 1h, and slowly add 0.6 parts of potassium persulfate dropwise, control the temperature at 75-80°C, and continue the reaction for 1h to make a homogeneous mixture, cool to 40°C, and use Ammonia water is used to adjust the pH to 8 to 9 to prepare a styrene-acrylic emulsion for use.

[0063] Wherein, the butyl acrylate (BA) used in Preparation...

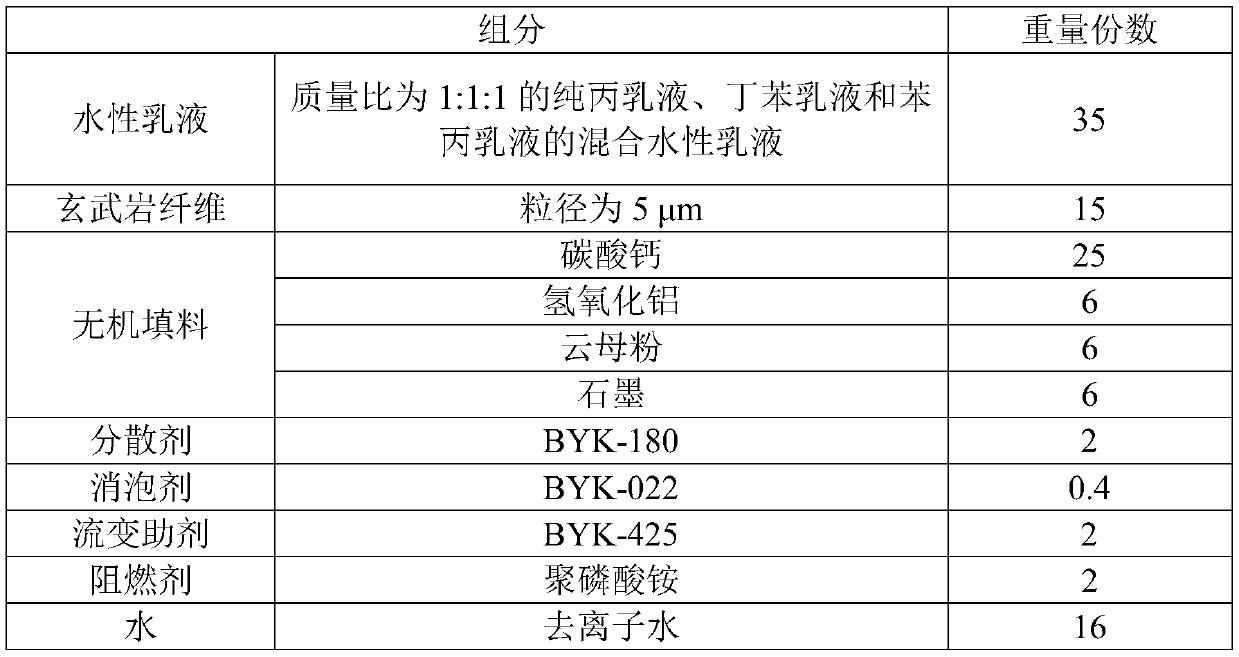

Embodiment 1

[0066] The present embodiment provides a kind of water-based damping coating, and described water-based damping coating comprises the following components in parts by weight:

[0067]

[0068] The preparation method of water-based damping coating described in the present embodiment comprises the following steps:

[0069] (1) Mix and stir 35 parts of water-based emulsion (pure acrylic emulsion, styrene-butadiene emulsion, and styrene-acrylic emulsion with a mass ratio of 1:1:1) and 15 parts of deionized water, and the mixing speed is 900rpm / min , the time of mixing and stirring is 15min, and the aqueous emulsion dilution is obtained;

[0070] (2) Add 2 parts of dispersant (BYK-180), 0.4 parts of antifoaming agent (organic silicon defoaming agent) and 15 parts of basalt fiber to the aqueous emulsion diluent obtained in step (1), mix and stir The speed is 900rpm / min, the time of mixing and stirring is 15min, and the mixed solution A is obtained;

[0071] (3) Add 43 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com