Method for obtaining molybdenum disulfide nanosheet through simple intercalation stripping

A molybdenum disulfide and nanosheet technology is applied in the field of simple intercalation and exfoliation to prepare molybdenum disulfide nanosheets, which can solve the problems of difficulty in large-scale production, harsh equipment requirements and high temperature, and achieves easy washing and removal, low cost and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

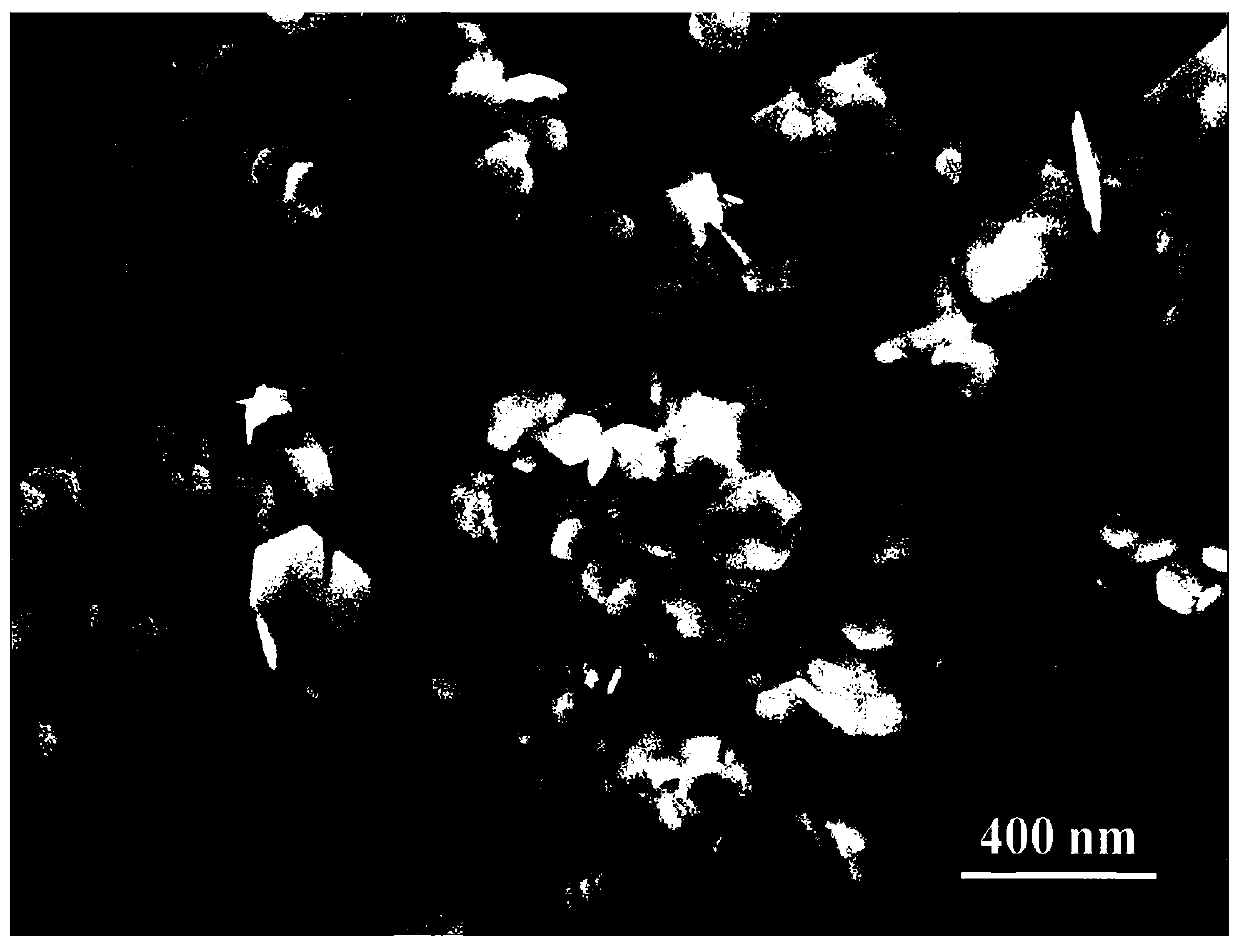

[0030] In this example, the preparation of molybdenum disulfide nanosheets with a thickness of 50 to 300 nm by intercalation exfoliation is taken as an example to illustrate the specific implementation steps of the method for obtaining molybdenum disulfide nanosheets by simple intercalation exfoliation in the present invention:

[0031] Step 1: Use molybdenum disulfide (analytical pure) with a particle size of micron as the raw material. ) in deionized water and mixed thoroughly to obtain a dispersion system.

[0032] See figure 1 Shown is the scanning electron microscope image of the raw material molybdenum disulfide, which shows that the molybdenum disulfide before peeling has a micron-scale lamellar structure with a relatively large thickness and irregular morphology.

[0033] The second step: heat the dispersion system prepared in the first step to 180-200°C in a high-pressure reactor, and perform intercalation treatment for 3-6 hours. A certain high pressure is generate...

Embodiment 2

[0041] In this embodiment, the method for obtaining molybdenum disulfide nanosheets by simple intercalation and exfoliation uses high-purity molybdenum disulfide with a particle size of micron as a raw material to prepare molybdenum disulfide nanosheets. The steps are as follows:

[0042] 1) Using magnesium chloride and sodium sulfide as intercalation agents, mix molybdenum disulfide, magnesium chloride and sodium sulfide with deionized water in a mass ratio of 50-100:1:0.5-1:600, and stir to obtain a dispersion system; Units of mass are grams or kilograms.

[0043] 2) Heat the dispersion system prepared in step 1) in a high-pressure reactor to 180-200°C for intercalation treatment, and the duration of intercalation treatment is 3-6 hours;

[0044] 3) Cool the dispersion system obtained in step 2) to room temperature, and then use ultrasonic treatment for peeling, and the duration of ultrasonic peeling is 30-60 minutes;

[0045] 4) The dispersion system obtained in step 3) wa...

Embodiment 3

[0047] The method for obtaining molybdenum disulfide nanosheets described in this example is different from Example 2 in that in step 3), 50 mL of the dispersion obtained after step 2) is placed in a beaker, Add 100-150mL of deionized water, and then place the beaker in a KQ-500B ultrasonic cleaner (power 50W, frequency 50KHz) for 40-50min to obtain relatively uniform single-layer or few-layer molybdenum disulfide nanoparticles. tablet dispersion system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com