Preparation method of filler for efficiently purifying phosphatidylcholine

A high-efficiency technology for purifying phosphatidylcholine, applied in separation methods, chemical instruments and methods, alkali metal compounds, etc., to achieve the effects of improving stability, good mechanical strength, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

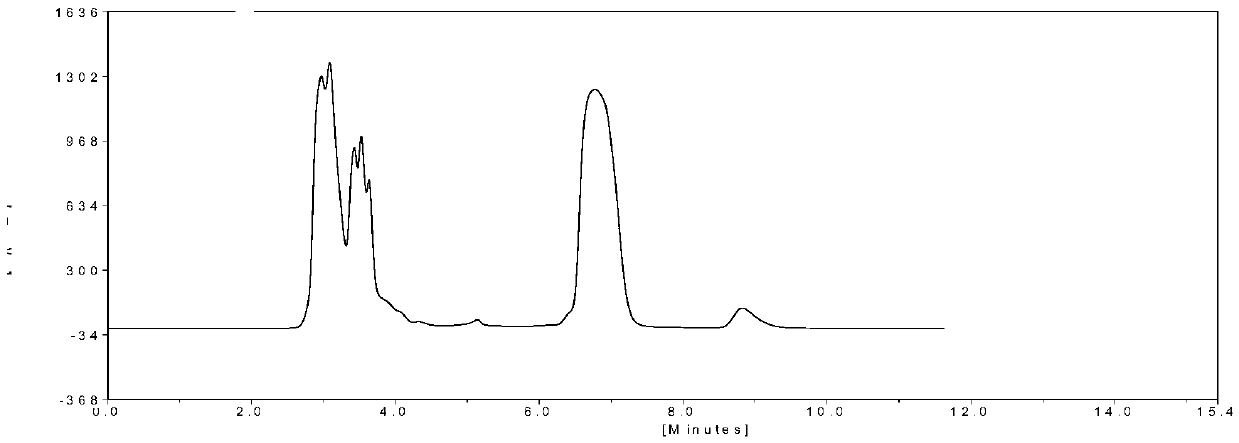

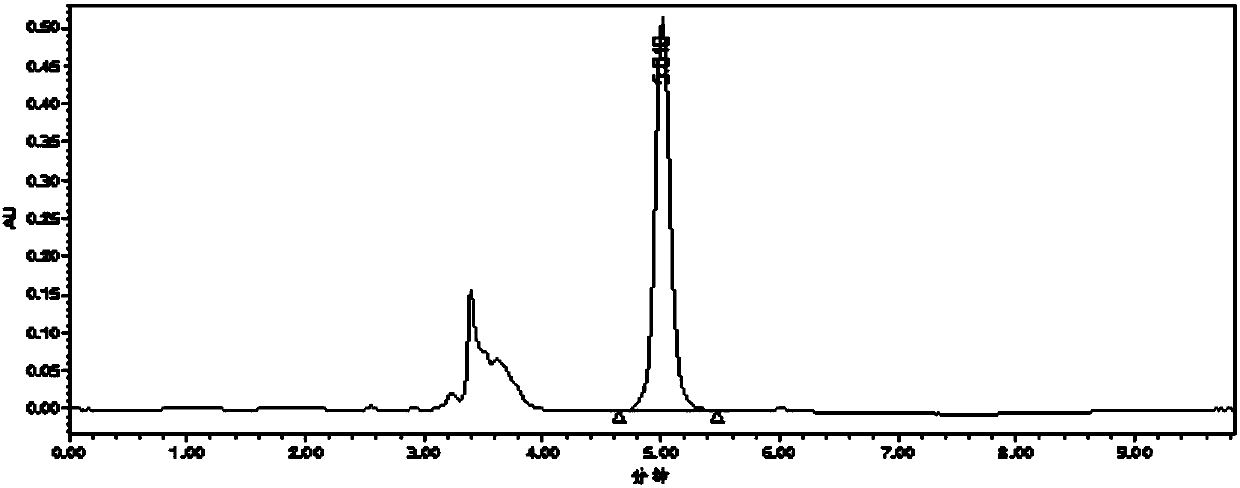

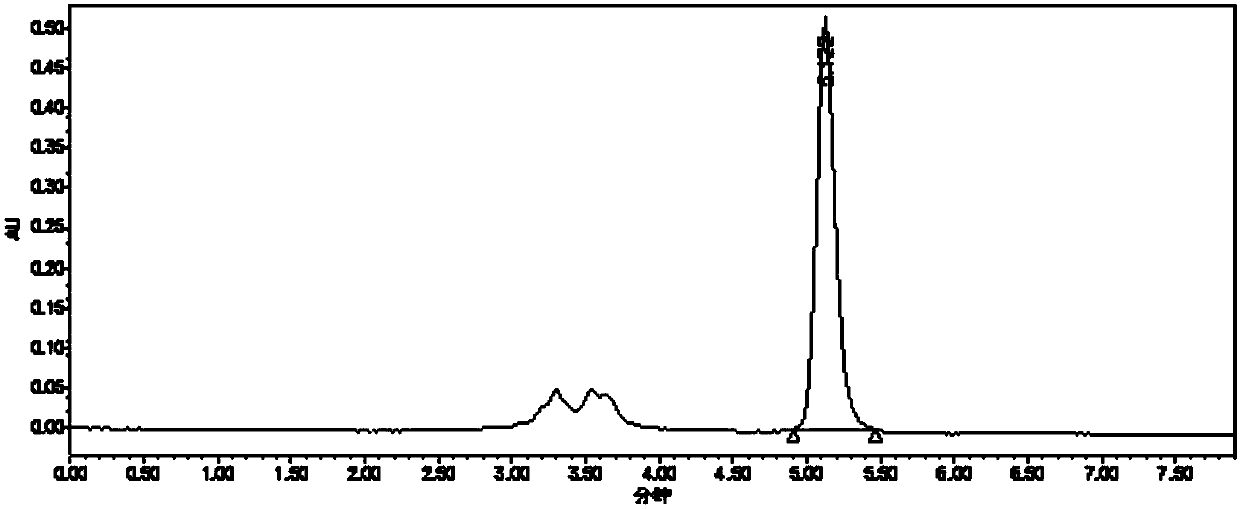

Image

Examples

Embodiment 1

[0033] A preparation method for a filler for efficiently purifying phosphatidylcholine, comprising the following steps:

[0034] 1), uniformly mix high-purity water with a resistivity greater than 18.2MΩ and a surfactant to obtain an aqueous solution with a surfactant concentration of 30g / L, that is, the water phase; the surfactant consists of 1.8% by weight Tween 20 and 0.01% by weight % sodium dodecyl sulfonate composition;

[0035] 2), according to the weight ratio of 10 parts by weight of methyl acrylate, 80 parts by weight of divinylbenzene and 10 parts by weight of N-vinylpyrrolidone, mix uniformly to obtain an oil phase; The total content of m-divinylbenzene and p-divinylbenzene is greater than 80%;

[0036] 3) Add the oil phase to the water phase under shearing and stirring to form a uniform and stable oil-in-water O / W emulsion, use free radicals to initiate and heat up to 40°C to initiate polymerization, filter with filter membrane or filter paper and wash 3 times, ...

Embodiment 2

[0039] A preparation method for a filler for efficiently purifying phosphatidylcholine, comprising the following steps:

[0040] 1), the resistivity is greater than the high-purity water of 18.2MΩ and tensio-active agent are evenly mixed, obtain the aqueous solution that tensio-active agent concentration is 18g / L, i.e. water phase; Surfactant is made up of Triton X-65 of 1.2% by weight and Composition of 0.2% sodium dodecylbenzenesulfonate by weight percentage;

[0041] 2), according to the weight ratio of 16 parts by weight of 2-ethyl methacrylate, 70 parts by weight of divinylbenzene and 14 parts by weight of N-vinylpyrrolidone, mix uniformly to obtain an oil phase; The total content of divinylbenzene, m-divinylbenzene and p-divinylbenzene is greater than 80%.

[0042] 3) Add the oil phase to the water phase under shearing and stirring to form a uniform and stable oil-in-water O / W emulsion, use free radicals to initiate and heat up to 80°C to initiate polymerization, filter...

Embodiment 3

[0045]A preparation method for a filler for efficiently purifying phosphatidylcholine, comprising the following steps:

[0046] 1), the resistivity is greater than the high-purity water of 18.2MΩ and tensio-active agent are evenly mixed, obtain the aqueous solution that tensio-active agent concentration is 3g / L, i.e. water phase; Surfactant consists of Triton X-100 of 0.3% by weight and Composition of 0.5% sodium dodecyl sulfonate by weight percentage;

[0047] 2), according to the weight ratio of 35 parts by weight of 2-methyl methacrylate, 60 parts by weight of divinylbenzene and 20 parts by weight of N-vinylpyrrolidone, mix uniformly to obtain an oil phase; The total content of divinylbenzene, m-divinylbenzene and p-divinylbenzene is greater than 80%.

[0048] 3), at room temperature, add azobisisobutyronitrile (0.2 g) to the above oil phase solution, stir to dissolve, then add to the above water phase solution, shear and stir (domestic S312-90 mechanical stirrer, The rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com