Preparation method for yak bone calcium-containing extract

A technology of extract and yak bone, which is applied in the field of preparation of calcium-containing extract of yak bone, can solve the problems of complex production operation, complex operation process of bone products, easily damaged amino acids, etc., and achieves low corrosion and environmental pollution, and is easy to be damaged. The effect of human body absorption and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

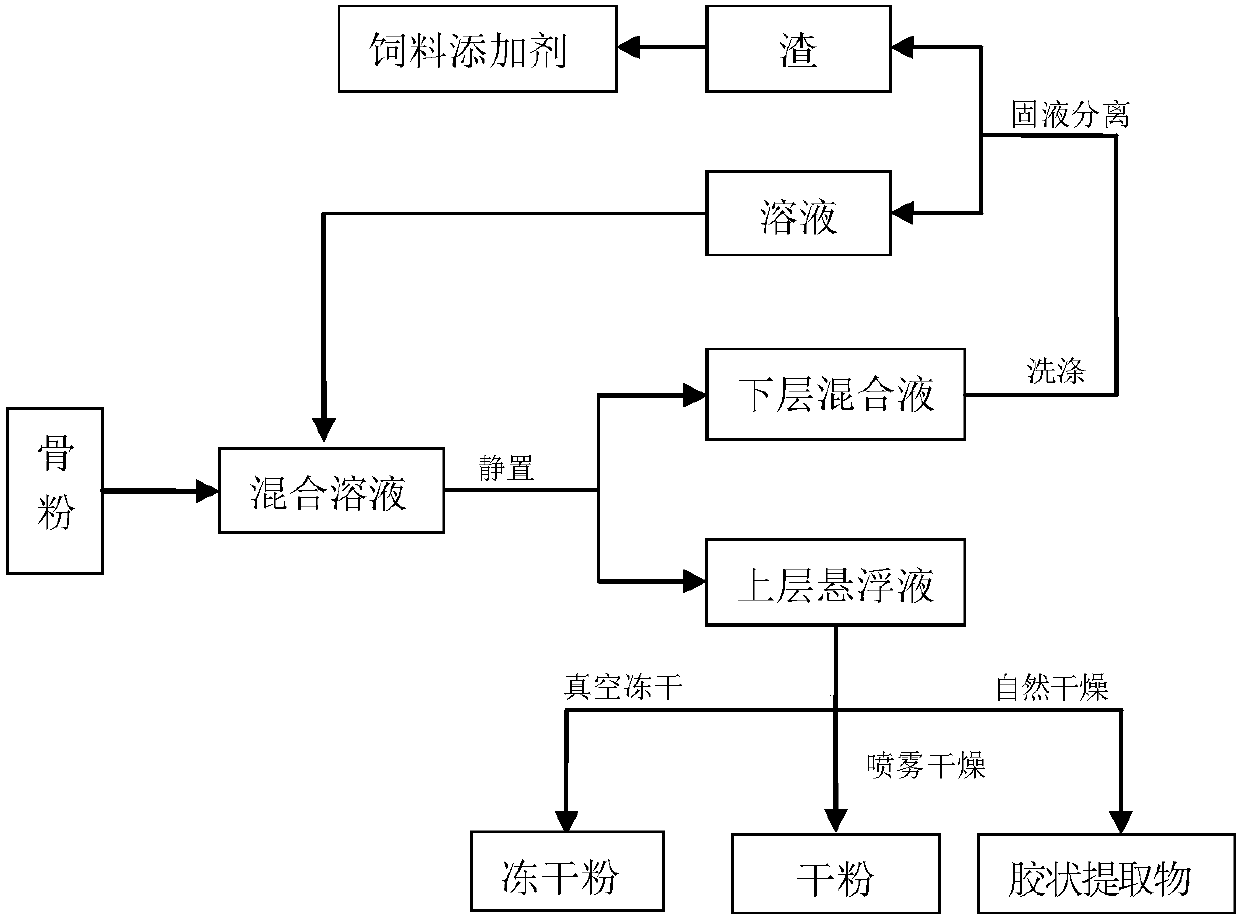

[0022] Step 1: Add 100 g of bone meal to 1 L of 3.2% dilute hydrochloric acid solution, stir at room temperature for 1.5 h, then let stand for 2 h until the mixture is separated to obtain a lower mixed liquid and an upper suspended liquid;

[0023] Step 2: Centrifuge the lower mixed solution to separate the solid from the liquid, mix the obtained supernatant with the above-mentioned upper suspension, wash the precipitate twice with water and separate the solid from the liquid; dry the washed precipitate and pulverize it as Feed additives, recovering the separated washing water for the preparation of dilute hydrochloric acid solution;

[0024] Step 3: Dry the upper layer suspension in Step 1 naturally under ventilated conditions to obtain 98.4 g of hydrous colloidal extract, which can be used as an additive in the production of liquid drinks or powdered granules.

[0025] For example: Dissolve 3g of colloidal extract in 90mL of 80°C hot water to obtain a colorless, odorless aqu...

example 2

[0027] Step 1: Add 500 g of bone meal to 5 L of 3.2% dilute hydrochloric acid solution, stir at room temperature for 2 hours, and then let stand for 2.5 hours until the mixture is separated into layers to obtain a lower mixture and an upper suspension;

[0028] Step 2: Wash the lower mixed solution with water for 3 times and separate the solid from the liquid; process the washed sediment and washing water according to the above-mentioned Example 1;

[0029] Step 3: The upper layer suspension in Step 1 was naturally dried under ventilated conditions to obtain 481.4 g of water-containing colloidal extract, which can be used as an additive in the production of liquid drinks or powdered granules.

[0030] Such as: dissolving 6g of colloidal extract in 200mL of hot water at 76°C to obtain a colorless, odorless aqueous solution containing calcium extract (with a little white precipitate), pH 2, and calcium content 15.2%. In addition, add 2 g of citric acid to 6 g of colloidal extrac...

example 3

[0032] Step 1: Add 1000g of bone meal to 10L of 3.2% dilute hydrochloric acid solution, stir at room temperature for 2.5 hours, then let stand for 3 hours until the mixed solution is separated to obtain the lower mixed solution and the upper suspended solution;

[0033] Step 2: wash the lower mixed solution with water for 3 times and separate the solid from the liquid; process the washed sediment and washing water according to Example 1;

[0034] Step 3: Vacuum freeze-dry the upper layer suspension obtained in Step 1 and pulverize to obtain 705.3 g of white, odorless freeze-dried powder containing calcium extract.

[0035] Or the upper layer suspension obtained in step 1 is spray-dried to obtain 702.6 g of white, odorless calcium-containing extract dry powder.

[0036] After testing, the obtained calcium-containing extract has a calcium content of 14.7%, a total phosphorus content of 7.35%, and is rich in other minerals and nutritive organic matter. It is suitable for additive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com