Fireproof and heat-insulating decorative composite board

A fireproof heat preservation and composite board technology, which is applied in fireproof coatings, covering/lining, buildings, etc., can solve the problems of fire safety hidden dangers and unreachable problems, so as to improve durability, fire resistance and overall heat preservation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

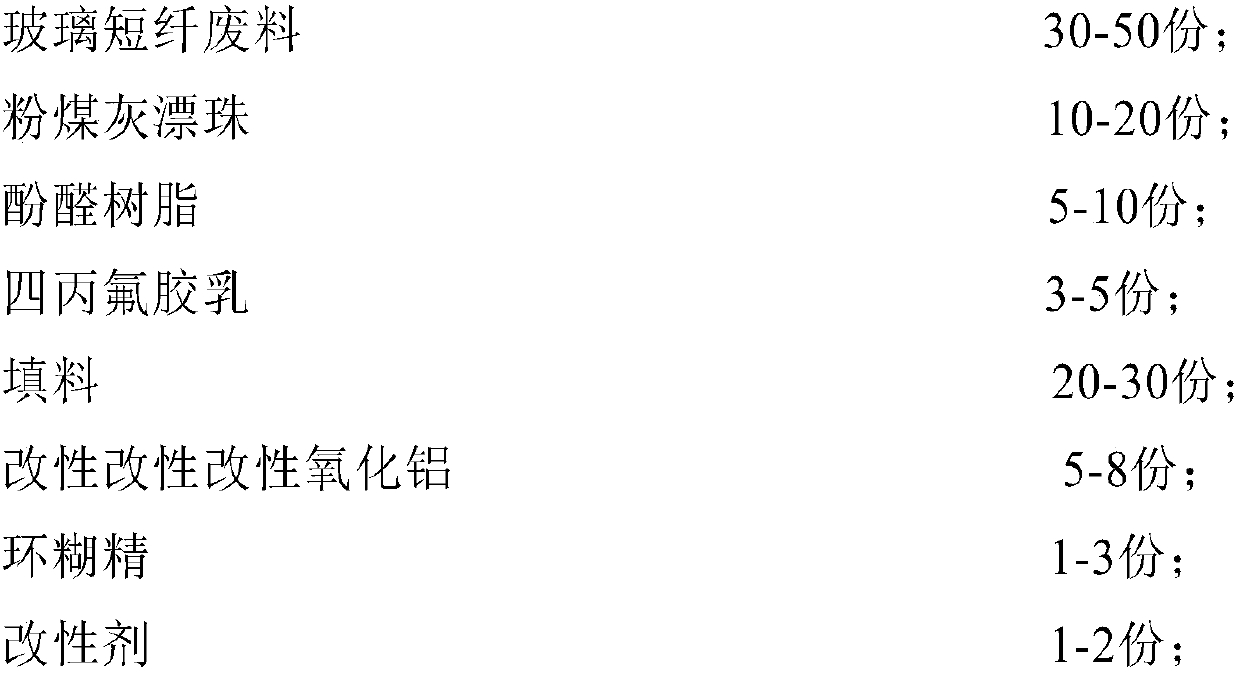

[0031] The fireproof thermal insulation decorative composite board of the present invention includes an aluminum alloy base layer, a foam material thermal insulation layer, and a foam material thermal insulation layer arranged on the foam material thermal insulation layer to allow the foam material thermal insulation layer to infiltrate from bottom to top. Reinforcement layer, coating and disposing an interface fireproof layer on the reinforcing layer and a surface anti-impact layer arranged on the interface fireproof layer; wherein, the surface anti-impact layer includes a stainless steel panel layer and an anti-impact paint layer.

[0032] The foamed material insulation layer foamed resin is a phenolic resin; in addition to the phenolic resin, the foamed material insulation layer also contains 3% foaming agent and 2% by mass of the foamed material insulation layer The foaming agent is n-pentane, the surfactant is sodium dodecyl sulfonate; the reinforcing layer is selected from P...

Embodiment 2

[0047] The fireproof thermal insulation decorative composite board of the present invention includes an aluminum alloy base layer, a foam material thermal insulation layer, and a foam material thermal insulation layer arranged on the foam material thermal insulation layer to allow the foam material thermal insulation layer to penetrate from bottom to top. A reinforced layer, an interface fireproof layer and a surface impact resistant layer arranged on the interface fireproof layer are coated on the reinforced layer; wherein, the surface impact resistant layer includes a stainless steel panel layer and an impact resistant paint layer.

[0048] The foamed resin in the foamed material insulation layer is polyurethane; the foamed material insulation layer not only contains polyurethane, but also contains 4% foaming agent and 3% of the foamed material insulation layer. Surfactant and 3% flame retardant, the blowing agent is polyisocyanate, the surfactant is polyethylene glycol 200, and...

Embodiment 3

[0062] The fireproof thermal insulation decorative composite board of the present invention includes an aluminum alloy base layer, a foam material thermal insulation layer, and a foam material thermal insulation layer arranged on the foam material thermal insulation layer to allow the foam material thermal insulation layer to penetrate from bottom to top. Reinforcement layer, coating and disposing an interface fireproof layer on the reinforcing layer and a surface anti-impact layer arranged on the interface fireproof layer; wherein, the surface anti-impact layer includes a stainless steel panel layer and an anti-impact paint layer.

[0063] The foamed material insulation layer foamed resin is polyvinyl chloride; the foamed material insulation layer contains not only polyvinyl chloride, but also contains a foaming agent and a 3% mass percentage of the foamed material insulation layer 5% flame retardant, the blowing agent is sodium bicarbonate, the flame retardant is antimony oxide;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com