Graphene modified heat-radiation-corrosion resistant fluorocarbon functional coating and preparation method thereof

A graphene modification, functional coating technology, applied in anti-corrosion coatings and other directions, to achieve excellent abnormal temperature curing, improve heat dissipation, and excellent overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

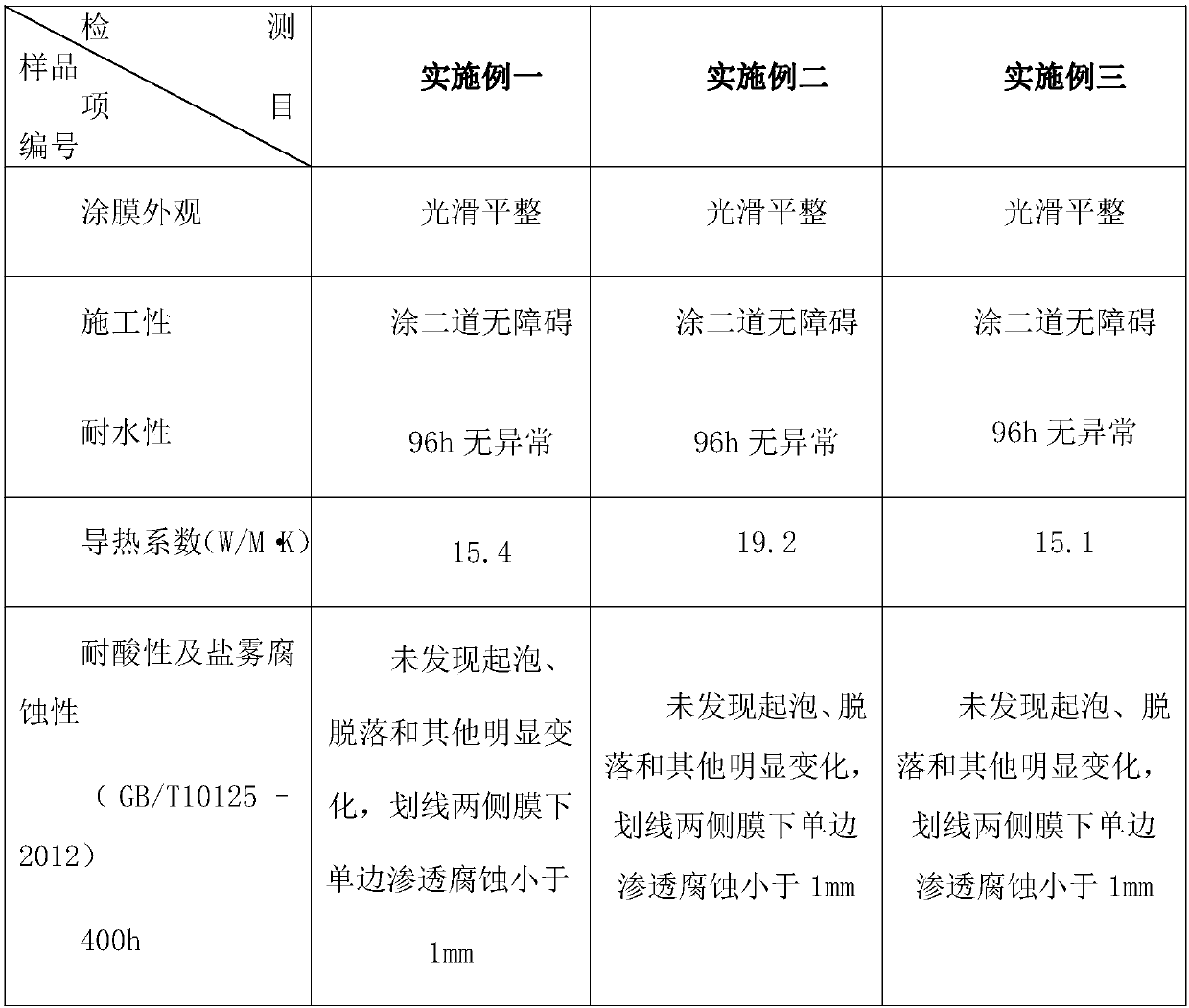

Examples

Embodiment 1

[0028] 1. Preparation of functionalized graphene dispersion:

[0029] (1) Acyl chloride of graphene oxide:

[0030] First, add graphene oxide to an appropriate amount of water to prepare a solution with a concentration of 10g / L, and shake the solution to make ultrasonic dispersion for 40-60min to obtain a graphene oxide aqueous dispersion with a concentration of 10g / L;

[0031] Next, take 50 mL of graphene oxide aqueous dispersion and heat it to 45°C, then add 0.5 g of monochloroacetic acid, 0.5 g of sodium hydroxide and 15 g of ethanol, and stir for 30 min to react the carboxyl groups on the graphene oxide by esterification Converted to an acid chloride group to form a primary reactant;

[0032] (1) amidation of graphene oxide: 3 g of cetyl trimethyl ammonium bromide is added to the primary reactant to convert the acid chloride group generated on the graphene oxide into an amide, thereby generating a stable covalent bond Functionalized graphene dispersion;

[0033] (2) Emu...

Embodiment 2

[0043] Example 2: The difference from Example 1 is that: when preparing the functionalized graphene dispersion, a graphene oxide aqueous dispersion with a solubility of 20 g / L was prepared.

Embodiment 3

[0044] Embodiment 3: First, weigh each component according to the following formula: water-based FEVE fluorocarbon resin emulsion 45g, polymethyl methacrylate emulsion 5g, functionalized graphene dispersion 15mL in Example 1, radiation-type inorganic substance 5g , 16g of pigments and fillers, 14.5g of additives, 15g of deionized water;

[0045] The radiation type inorganic substance is indium tin oxide (ie: ITO, wherein the mass ratio of indium oxide and tin oxide is In 2 O 3 :SnO 2 =9:1);

[0046]8g montmorillonite and 8g rutile titanium dioxide are used as pigments and fillers;

[0047] The auxiliary agent is 0.5g polyether defoamer (such as GPE), 1g polycarboxylate sodium salt type dispersant (such as SN-5040), and 1g wetting agent (ie: sulfonic acid anionic surfactant, such as SN WET991) , 3g polyvinyl alcohol thickener (such as PEG800 or PEG600), 1g film forming agent (ie: dodecyl alcohol ester), 3g antifreeze agent (ie: propylene glycol) and 5g PH regulator (such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com