Negative pole piece and preparation method thereof

A technology of negative pole piece and negative pole, which is applied in the field of negative pole piece and its preparation, can solve the problems of poor compatibility and fast decay of cycle life, and achieve the effects of controllable thickness, improved ion conductivity, and shortened diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

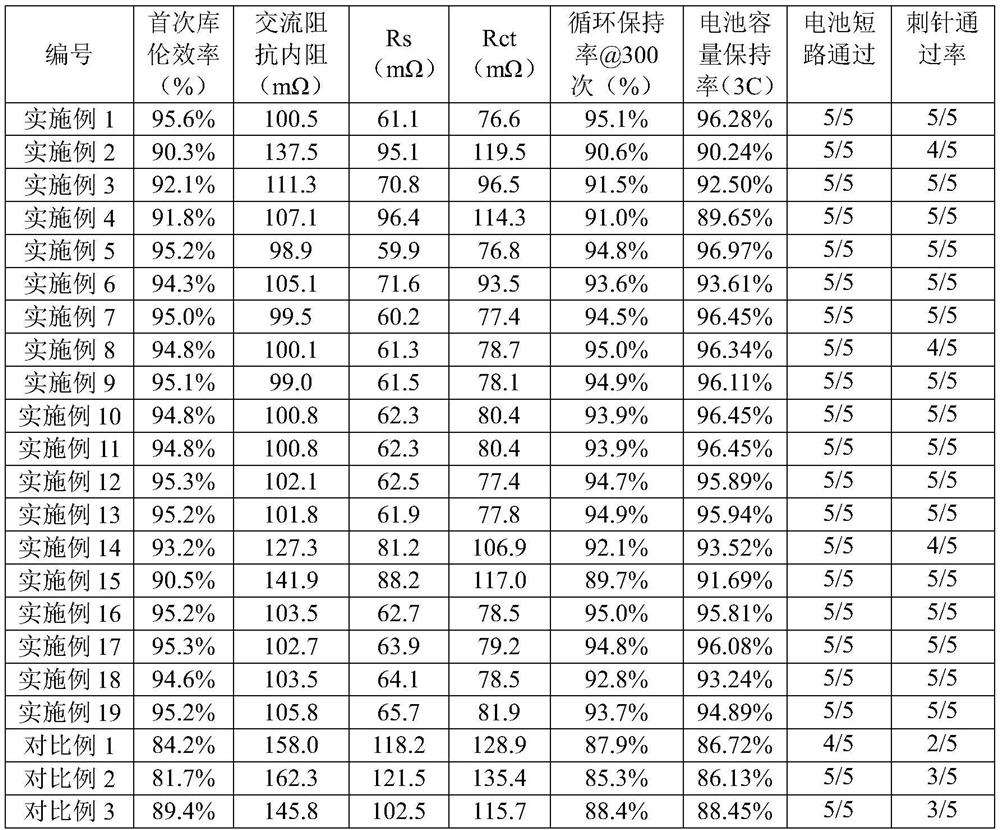

Examples

preparation example Construction

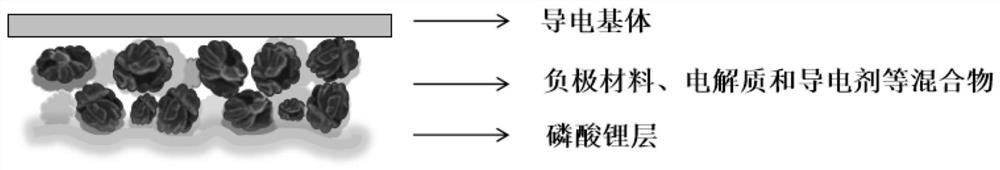

[0039] The invention provides a preparation method of a negative pole piece, comprising the following steps:

[0040] S1. In parts by weight, mix 87-97 parts of negative electrode active materials and 1-10 parts of solid electrolyte, and perform mechanical ball milling. The mechanical ball milling is carried out under vacuum conditions. After the mechanical ball milling, add in a solvent and stir, and then perform ultrasonic treatment in sequence , Filtration, washing and drying operations to obtain the negative electrode composite material, where the solvent can be selected from acetone, acetonitrile, dimethylformamide, tetrahydrofuran, toluene, and the final material needs to be fully dispersed and mixed uniformly;

[0041] Dissolve the prepared negative electrode composite material, 0.1-5 parts of conductive agent, 0-4 parts of thickener and 1-4 parts of binder in 90-130 parts of organic dispersant to obtain slurry, and coat the slurry On the current collector, the coating ...

Embodiment 1

[0054] A method for preparing a negative pole piece, comprising the following steps:

[0055] S1. Mix 90g of negative electrode active material and 4.5g of solid electrolyte and then carry out mechanical ball milling. The mechanical ball milling is carried out under vacuum conditions. After mechanical ball milling, add 270g of solvent acetonitrile to stir, and then perform ultrasonic treatment, filtration, washing and drying operations in sequence to obtain negative electrode composite materials. ;

[0056] Disperse the prepared negative electrode composite material, 3g conductive agent, and 2g binder in 101.5g organic dispersant, and coat the slurry on the current collector with a coating amount of 15mg / cm 2 , drying under vacuum conditions, the drying temperature is 100 ° C, and the drying time is 5 hours to form the negative electrode substrate, and the negative electrode substrate is placed on the sample stage in the vacuum chamber;

[0057] S2. Make lithium phosphate as ...

Embodiment 2

[0061] A method for preparing a negative pole piece, comprising the following steps:

[0062] S1. Mix 87g of negative electrode active material and 1g of solid electrolyte, and perform mechanical ball milling. The mechanical ball milling is carried out under vacuum conditions. After mechanical ball milling, add 174g of solvent (acetone) to stir, and then perform ultrasonic treatment, filtration, washing and drying operations in sequence to obtain negative electrode composite Material;

[0063] Dissolve the prepared negative electrode composite material, 1 g of conductive agent and 1 g of binder in 90 g of organic dispersant to obtain a slurry, and coat the slurry on the current collector with a coating amount of 5 mg / cm 2 , drying under vacuum conditions, the drying temperature is 80°C, and the drying time is 10h to form the negative electrode substrate, and place the negative electrode substrate on the sample stage in the vacuum chamber;

[0064] S2. Make lithium phosphate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com