Three-dimensional carbon fiber preform enhanced yttrium oxide-aluminum oxide complex-phase ceramic composite material and preparation method thereof

A technology of three-dimensional carbon fiber and composite ceramics, which is applied to ceramic products, other household appliances, applications, etc., and can solve the problem of less gaseous raw materials, unsatisfactory deposition characteristics, and no three-dimensional carbon fiber prefabricated reinforced yttrium oxide-alumina composite ceramics Composite material research reports and other issues, to achieve the effect of overcoming brittleness, excellent oxidation resistance, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

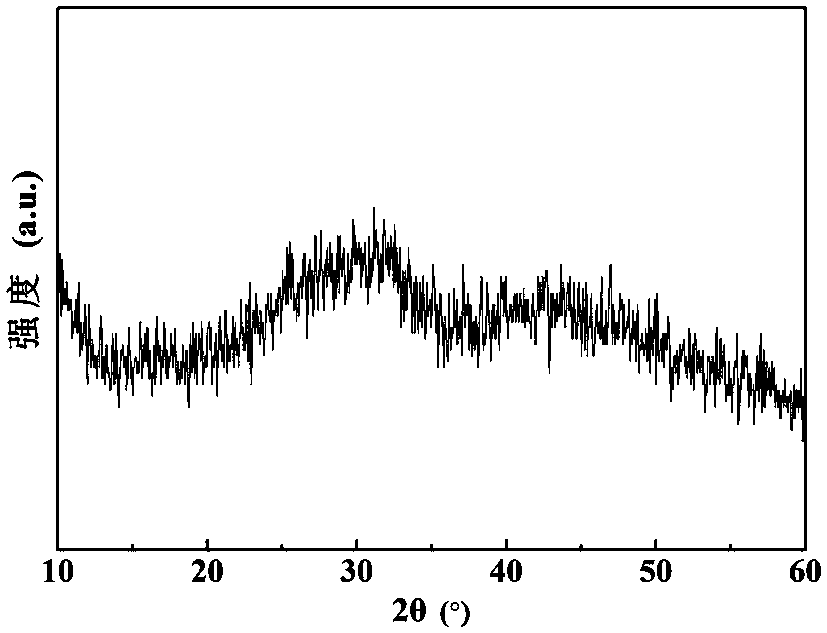

Image

Examples

Embodiment 1

[0043] A three-dimensional carbon fiber preform reinforced yttrium oxide-alumina composite ceramic composite material of the present invention, comprising a three-dimensional carbon fiber preform and a yttrium oxide-alumina composite ceramic, wherein the yttrium oxide-alumina composite ceramic is a matrix, and the three-dimensional The carbon fiber preform is the reinforcing phase, and the yttrium oxide-alumina composite ceramics are uniformly filled in the gaps of the three-dimensional carbon fiber preform, and in the yttrium oxide-alumina composite ceramic matrix, Y 2 o 3 with Al 2 o 3 The molar ratio is 3:5 (corresponding to the YAG crystal phase composition). In this implementation, the porosity of the three-dimensional carbon fiber preform reinforced yttrium oxide-alumina composite ceramic composite material is 14.3%.

[0044] In this embodiment, the three-dimensional carbon fiber prefabricated part is a three-dimensional carbon fiber prefabricated part obtained by stac...

Embodiment 2

[0056] A three-dimensional carbon fiber preform reinforced yttrium oxide-alumina composite ceramic composite material of the present invention, comprising a three-dimensional carbon fiber preform and yttrium oxide-alumina composite ceramics, wherein the yttrium oxide-alumina composite ceramics is a matrix, Al 2 o 3 The molar content in the composite ceramics is 5%, the three-dimensional carbon fiber preform is the reinforcing phase, and the yttrium oxide-alumina composite ceramics is evenly filled in the gaps of the three-dimensional carbon fiber preform. In this implementation, the three-dimensional carbon fiber preform reinforces the yttrium oxide - The porosity of the alumina multiphase ceramic composite is 10.8%.

[0057] In this embodiment, the three-dimensional carbon fiber prefabricated part is a three-dimensional carbon fiber prefabricated part with a three-dimensional four-way weaving structure, and the volume fraction of fibers in the three-dimensional carbon fiber p...

Embodiment 3

[0069] A three-dimensional carbon fiber preform reinforced yttrium oxide-alumina composite ceramic composite material of the present invention, comprising a three-dimensional carbon fiber preform and yttrium oxide-alumina composite ceramics, wherein the yttrium oxide-alumina composite ceramics is a matrix, Al 2 o 3 The molar content in the composite ceramics is 95%, the three-dimensional carbon fiber preform is the reinforcing phase, and the yttrium oxide-alumina composite ceramics are evenly filled in the gaps of the three-dimensional carbon fiber preform. In this implementation, the three-dimensional carbon fiber preform reinforces the yttrium oxide - The porosity of the alumina multiphase ceramic composite is 15.0%.

[0070] In this embodiment, the three-dimensional carbon fiber preform is a three-dimensional carbon fiber preform with a two-dimensional semi-woven structure, and the volume fraction of fibers in the three-dimensional carbon fiber preform is 46%.

[0071] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com