Carbon magnetic superstructure composite material and its preparation method and application

A composite material and superstructure technology, which is applied in the field of preparing carbon magnetic superstructure composite materials, can solve the problems of complex multi-steps and high cost, and achieve the effects of broad application prospects, low cost and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Accurately weigh 0.36g FeCl 3 ·6H 2 O was placed in an evaporating dish, 1 mL of deionized water was added, stirred to dissolve it fully, and a yellow clear solution was obtained, then 1.22 g (4 mmol) of sodium oleate was added and mixed well. Finally, the mixture was aged in an oven at 85° C. for 3 hours to obtain a transition metal salt-oleate complex.

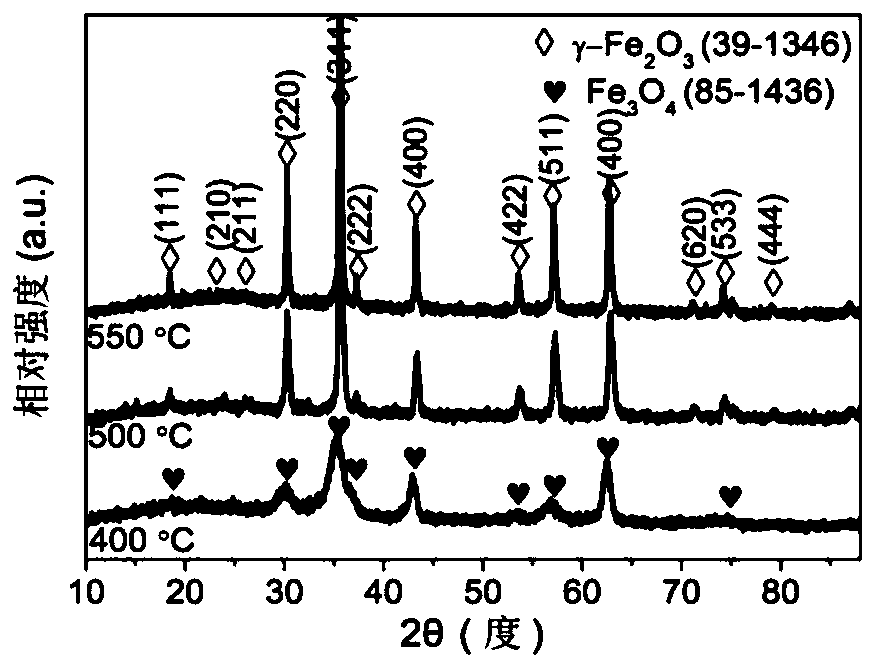

[0061] After cooling the above-mentioned newly prepared transition metal salt-oleate complex to room temperature, add 10 g of sodium sulfate particles, then fully grind it to powder with an agate mortar, place it in a tube furnace with an ark, and place it in a tube furnace. N 2 Under protection, the temperature was raised to 500°C at a heating rate of 5°C / min, kept for 3 hours, cooled, filtered and washed with deionized water several times, and finally dried at 100°C for 6 hours to obtain the carbon magnetic superstructure composite material.

[0062] The resulting composite material, its phase, and the morphology...

Embodiment 2

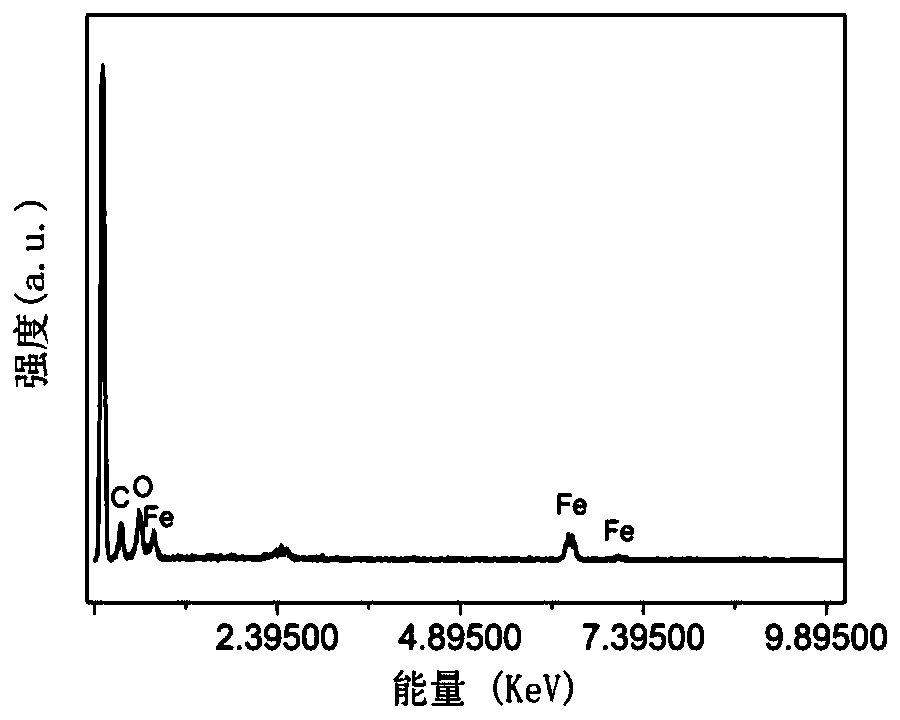

[0064] Same step as in Example 1, but the amount of sodium oleate is 3 mmol. The resulting product is a black powder, and the product structure observed under a scanning electron microscope is as follows: Figure 5 As shown, it can be seen that a layer of γ-Fe with a smaller size grows on the surface of the flake graphite 2 o 3 Spherical matrix with dimensions of 20 ± 2 nm. The atomic ratio of elements Fe:C=0.382 was obtained by energy spectrum analysis. Its static magnetic properties are as Figure 4 As shown, the saturation magnetization is 55.27emu·g -1 , The coercivity is 133.22Oe.

Embodiment 3

[0066] Same step as in Example 1, but the amount of sodium oleate is 5 mmol. The resulting product is a black powder, and the product structure observed under a scanning electron microscope is as follows: Figure 6 As shown, it can be seen that there is a layer of larger γ-Fe on the surface of the flaky graphite 2 o 3 Cubic matrix, with a size of 35±5nm, and a small number of matrix particles connected together. The energy spectrum analysis shows that the atomic ratio of Fe:C=0.117. Its static magnetic properties are as Figure 4 As shown, the saturation magnetization is 35.46emu·g -1 , the coercive force is 215.10Oe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com