Silicon carbon composite material, and preparation method and application thereof

A technology of silicon-carbon composite materials and composite materials, applied in electrical components, battery electrodes, circuits, etc., can solve the problem of low volume energy density and power energy density of silicon-carbon anode materials, which cannot meet the application requirements of battery anode materials, and harsh preparation conditions and other issues, to achieve the effects of superior cycle stability, limited electrode expansion, high-quality specific capacity and volume specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

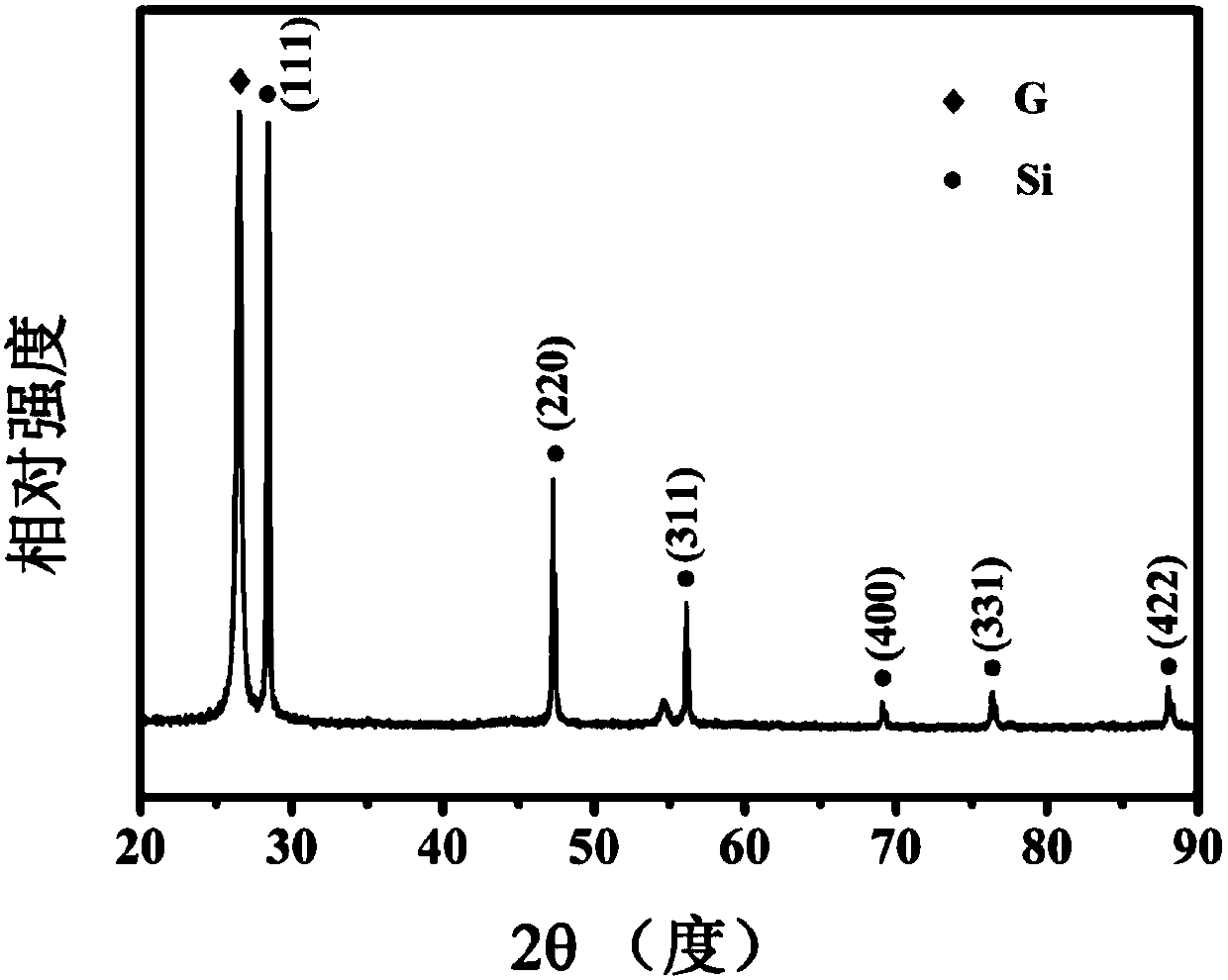

[0040] The preparation method of the silicon-carbon composite material is characterized in that it comprises the following steps:

[0041] (1) Combine silicate glass powder and sheet carbon material, perform wet ball milling, filter and dry to obtain a uniformly mixed mixture of silicate glass powder and sheet carbon material.

[0042] As a preferred technical solution, the particle size of the silicate glass powder is 5-10 microns. The method of obtaining silicate glass powder is as follows: washing and drying the glass with deionized water, then reducing the particle size of the glass by mechanical ball milling, and then sieving with 1000 meshes to screen out the glass powder whose particle size meets the requirements, so that The composite is more uniform in the subsequent preparation process. The silicate glass is sodium silicate glass or calcium silicate glass.

[0043] Sheet carbon material is a carbon material with a sheet structure, including one or more of natural g...

Embodiment 1

[0053] (1) The 5-10 micron glass powder and expanded graphite after ball milling are put into an agate jar for mechanical ball milling for 10 hours according to the mass ratio of 10:1 with alcohol as a ball milling agent to obtain a mixture of glass and graphite;

[0054] (2) heating the mixture of glass and graphite obtained in the step (1) to 1000° C. for 2 hours at a heating rate of 5° C. / min under an argon atmosphere;

[0055] (3) Grind the sample obtained in step (2) and mix it uniformly with magnesium powder and molten salt according to the mass ratio of 1:0.35:4, and then hydraulically form an ingot under a pressure of 40 MPa;

[0056] (4) Put the sample ingot obtained in step (3) into a tube furnace filled with argon and heat it to 700° C. for 3 hours at a heating rate of 5° C. / min to obtain a reacted mixture;

[0057] (5) Wash the reacted mixture obtained in step (4) in 1mol / L hydrochloric acid for 5 hours. Then it was washed in 0.5 mol / L hydrofluoric acid for 10 min...

Embodiment 2

[0065] (1) The 5-10 micron glass powder and expanded graphite after the ball milling are according to the ratio of mass ratio 10:0.8, with alcohol as the ball milling agent, put into an agate jar and mechanically ball mill for 10 hours to obtain a mixture of glass and graphite;

[0066] (2) heating the mixture of glass and graphite obtained in step (1) to 850° C. for 2 hours at a rate of temperature increase of 5° C. / min under an argon atmosphere;

[0067] (3) Grind the sample obtained in step (2) and mix it evenly with magnesium powder and molten salt according to the mass ratio of 1:0.35:5, and then hydraulically form an ingot under a pressure of 12 MPa;

[0068] (4) Put the sample ingot obtained in step (3) into a tube furnace filled with argon and heat it to 700° C. for 3 hours at a heating rate of 5° C. / min to obtain a reacted mixture;

[0069] (5) Wash the reacted mixture obtained in step (4) in 2mol / L hydrochloric acid for 3 hours. Then, it was washed in 0.2 mol / L hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com