Inorganic oxide quantum dot light emitting diode

A technology of quantum dot luminescence and inorganic oxides, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of non-radiative recombination, quantum dot charging, etc., and the method is simple, easy to process into films, The effect of improving the external quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

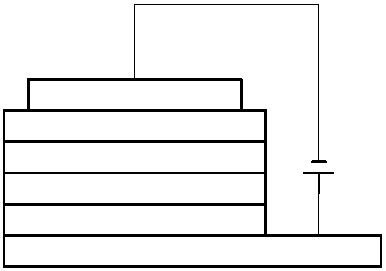

[0034] The substrate and anode are made of commercial ITO transparent conductive glass. After cleaning with cleaning solution, deionized water, acetone and isopropanol for 15 minutes each, treat it in a UV ozone cleaner for 20 minutes, and then transfer it into a glove box (O2<1ppm, H2O<1ppm) for spin coating.

[0035] On the cleaned ITO transparent conductive glass, spin-coat nano-molybdenum oxide at a speed of 3000 rpm for 50 s, and anneal at 150° C. for 30 min after spin coating to form a 10 nm hole injection layer.

[0036] On the molybdenum oxide layer, continue to spin-coat 8 mg / ml poly-TPD chlorobenzene solution at a speed of 3000 rpm for 30 seconds, and then anneal at 150° C. for 30 minutes to form a 30-nm hole injection layer. As a hole transport layer, poly-TPD has excellent hole transport ability.

[0037] The 15 mg / ml CdSe / CdS quantum dot n-hexane solution was spin-coated on the hole transport layer, and placed in the glove box for 30 minutes after completion, to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com