A kind of al with nano-encapsulated solid lubricant 2 o 3 /ti(c,n) nanocomposite ceramic cutting tool material and preparation method thereof

A solid lubricant, ceramic tool technology, applied in the field of ceramic tool materials and their preparation, can solve the problems of reduced mechanical properties such as tool material hardness, damage to tool material mechanical properties, low friction coefficient of tool materials, etc. The effect of low cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

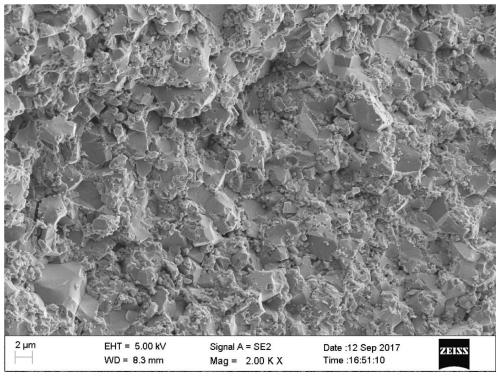

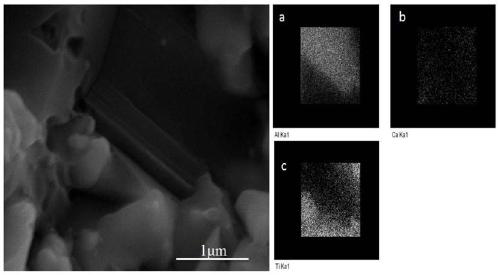

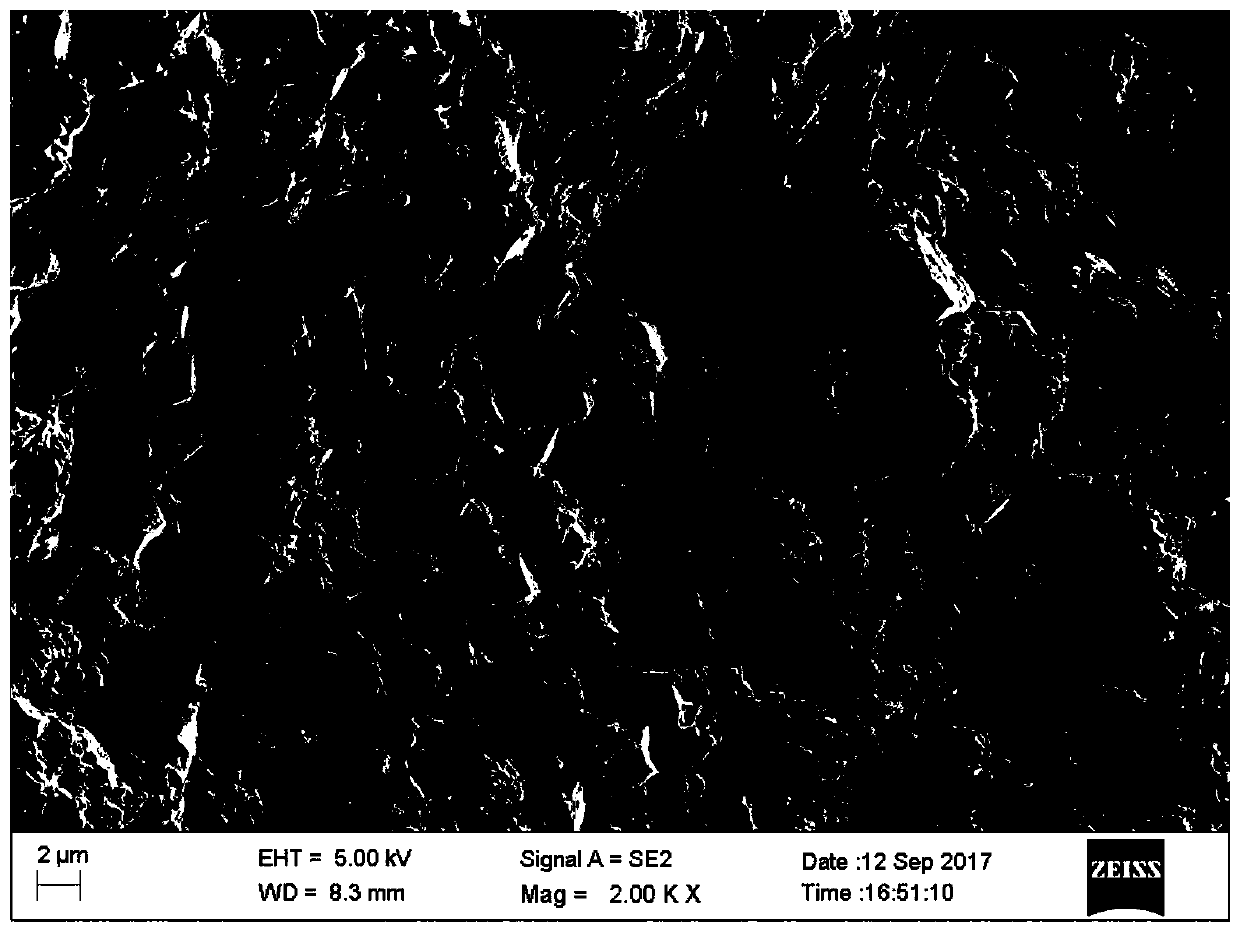

[0048] Embodiment 1: adding nano-CaF 2 @Al 2 o 3 Powdered Al 2 o 3 / Ti(C,N) Nanocomposite Ceramic Cutting Tool

[0049] Al 2 o 3 / Ti(C,N)-based ceramic cutter, the volume content ratio of raw materials is: Ti(C,N) is 22.16%, MgO is 0.5%, nano-CaF 2 @Al 2 o 3 Powder is 10%, the balance is Al 2 o 3 .

[0050] First, weigh the raw materials, add polyvinylpyrrolidone into absolute ethanol, ultrasonically disperse and mechanically stir for 20-30min, add nano-CaF 2 @Al 2 o 3 For the powder, continue ultrasonic dispersion and mechanical stirring for 60-120 minutes to obtain a dispersion. Add polyethylene glycol to absolute ethanol respectively, ultrasonically disperse and mechanically stir for 20-30min, add A1 2 o 3 For powder, continue to ultrasonically disperse and mechanically stir for 20-30 minutes to obtain A1 2 o 3 Dispersions. Add polyethylene glycol into absolute ethanol, ultrasonically disperse and mechanically stir for 20-30 minutes, and wait until it is ...

Embodiment 2

[0053] Embodiment 2: adding nano-CaF 2 @Al 2 o 3 Powdered Al 2 o 3 / Ti(C,N) Nanocomposite Ceramic Cutting Tool

[0054] Al 2 o 3 / Ti(C,N)-based ceramic cutter, the volume content ratio of raw materials is: Ti(C,N) is 23.4%, MgO is 0.5%, nano-CaF 2 @Al 2 o 3 Powder is 5%, the balance is Al 2 o 3 .

[0055] First, weigh the raw materials, add polyvinylpyrrolidone into absolute ethanol, ultrasonically disperse and mechanically stir for 20-30min, add nano-CaF 2 @Al 2 o 3 For the powder, continue ultrasonic dispersion and mechanical stirring for 60-120 minutes to obtain a dispersion. Add polyethylene glycol to absolute ethanol respectively, ultrasonically disperse and mechanically stir for 20-30min, add A1 2 o 3 For powder, continue to ultrasonically disperse and mechanically stir for 20-30 minutes to obtain A1 2 o 3 Dispersions. Add polyethylene glycol into absolute ethanol, ultrasonically disperse and mechanically stir for 20-30 minutes, and wait until it is co...

Embodiment 3

[0057] Embodiment 3: adding nano-CaF 2 @Al 2 o 3 Powdered Al 2 o 3 / Ti(C,N) Nanocomposite Ceramic Cutting Tool

[0058] Al 2 o 3 / Ti(C,N)-based ceramic cutter, the volume content ratio of raw materials is: Ti(C,N) is 20.92%, MgO is 0.5%, nano-CaF 2 @Al 2 o 3 Powder is 15%, the balance is Al 2 o 3 was 63.58%.

[0059] First, weigh the raw materials, add polyvinylpyrrolidone into absolute ethanol, ultrasonically disperse and mechanically stir for 20-30min, add nano-CaF 2 @Al 2 o 3 For the powder, continue ultrasonic dispersion and mechanical stirring for 60-120 minutes to obtain a dispersion. Add polyethylene glycol to absolute ethanol respectively, ultrasonically disperse and mechanically stir for 20-30min, add A1 2 o 3 For powder, continue to ultrasonically disperse and mechanically stir for 20-30 minutes to obtain A1 2 o 3Dispersions. Add polyethylene glycol into absolute ethanol, ultrasonically disperse and mechanically stir for 20-30 minutes, and wait unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com