Cement color brick produced by shield tunnel spoil and preparation method thereof

A technology of shield tunneling and cement, which is applied in the field of building materials, can solve the problems of people's life safety and property safety hazards, environmental pollution, etc., and achieve the effects of good frost resistance, excellent corrosion resistance, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

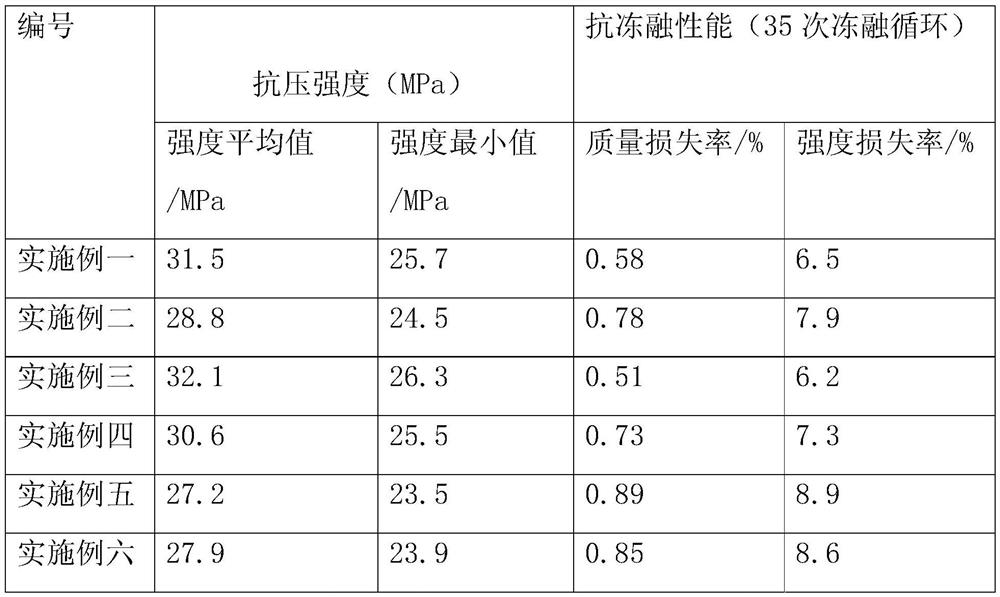

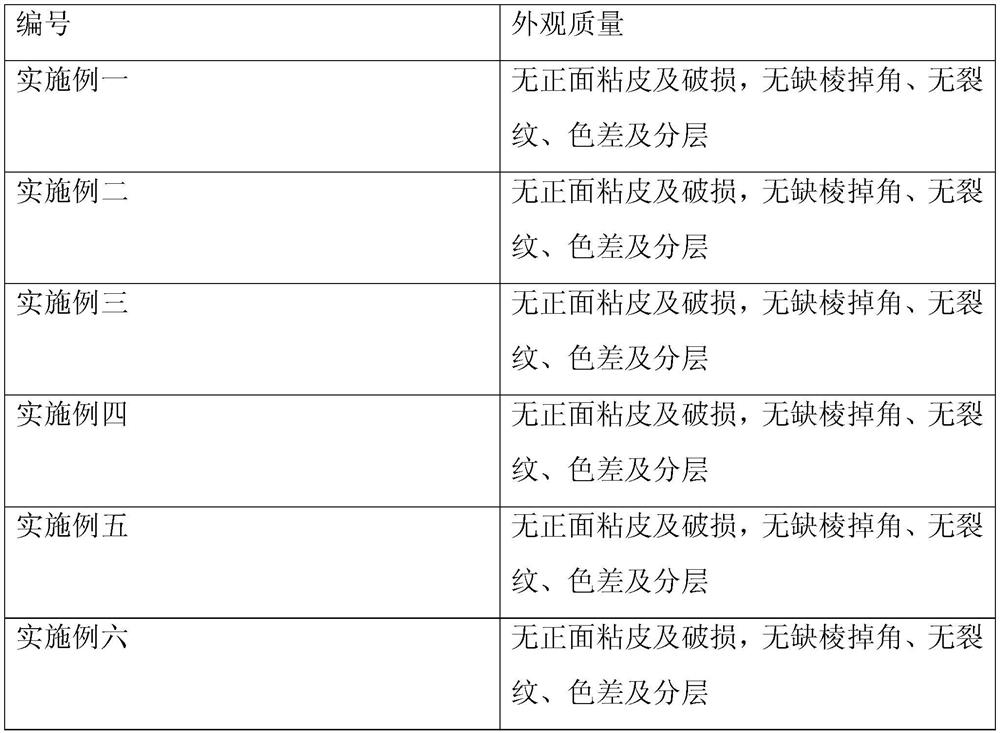

Examples

preparation example Construction

[0027]In this embodiment, the method for preparing the modified loofah fiber includes the following steps:

[0028](1) Preparation of a solution for modification, including preparation of alkaline mixed solution A and acidic mixed solution B, where:

[0029]The preparation method of the alkaline mixed solution A is: taking 16.7 parts of NaOH and 1.3 parts of urea by weight, placing them in 82 parts of deionized water, and stirring and dissolving;

[0030]The preparation method of the acidic mixed solution B is: take 25 parts by weight of H2SO4, 60 parts Na2SO4And 55 parts of ZnSO4Put it in 860 parts of deionized water and stir to dissolve;

[0031](2) Preparation of modified loofah fiber: After cutting the loofah into small pieces, tear the loofah into a single piece of loofah silk, then put the loofah silk in the alkaline mixed solution A, heat up to 100 ℃, boil for 25 minutes, then take out the loofah silk Place it in acidic mixed solution B, soak for 10 minutes, then filter and collect the s...

Embodiment 1

[0041]The raw material of the cement color brick of this embodiment includes the following components by weight: 15 parts of cement, 55 parts of aggregate, 10 parts of fly ash, 0.5 part of hydroxypropyl methylcellulose, palygorskite powder (600-800 mesh) 7 parts, 7 parts of seaweed powder (600~800 mesh), 1 part of modified loofah fiber, 0.5 part of ramie fiber (monofilament length of 9-12mm), 1 part of bamboo charcoal fiber (monofilament length of 9-12mm), cement 0.5 parts of brightener, 1 part of iron oxide pigment, 20 parts of water; the aggregate is machine-made sand formed by the crushing of waste slag of shield tunnel, the fineness modulus of the machine-made sand is 2.6, MB is 1.4, and the content of stone powder is 12%.

[0042]In this embodiment, the method for preparing cement colored bricks includes the following steps:

[0043]a. Mix fly ash, palygorskite powder and seaweed powder in parts by weight, send them to a ball mill and grind them into 1000-1200 mesh particles, then mi...

Embodiment 2

[0053]The raw materials of the cement color brick of this embodiment include the following components by weight: 10 parts of cement, 65 parts of aggregate, 15 parts of fly ash, 0.3 part of hydroxypropyl methylcellulose, palygorskite powder (600-800 mesh) 10 parts, 10 parts of seaweed powder (600~800 mesh), 0.5 parts of modified loofah fiber, 1 part of ramie fiber (monofilament length 9-12mm), 0.5 part of bamboo charcoal fiber (monofilament length 9-12mm), cement 0.2 parts of brightener, 0.5 parts of iron oxide pigment, 17 parts of water; the aggregate is machine-made sand formed by crushing the waste slag of the shield tunnel, the fineness modulus of the machine-made sand is 3.1, the MB is 1.0, and the stone powder content is 10%.

[0054]In this embodiment, the method for preparing cement colored bricks includes the following steps:

[0055]a. Mix fly ash, palygorskite powder and seaweed powder in parts by weight, send them to a ball mill and grind them into 1000-1200 mesh particles, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com