Nickel-based self-fusing alloy powder for remanufacturing glass mold and welding process of nickel-based self-fusing alloy powder

A technology of nickel-based self-melting and glass molds, which is applied in the field of remanufacturing, can solve the problems of waste of resources, failure to recycle molds in time, and high replacement costs, and achieve the effects of prolonging service life, excellent self-melting, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

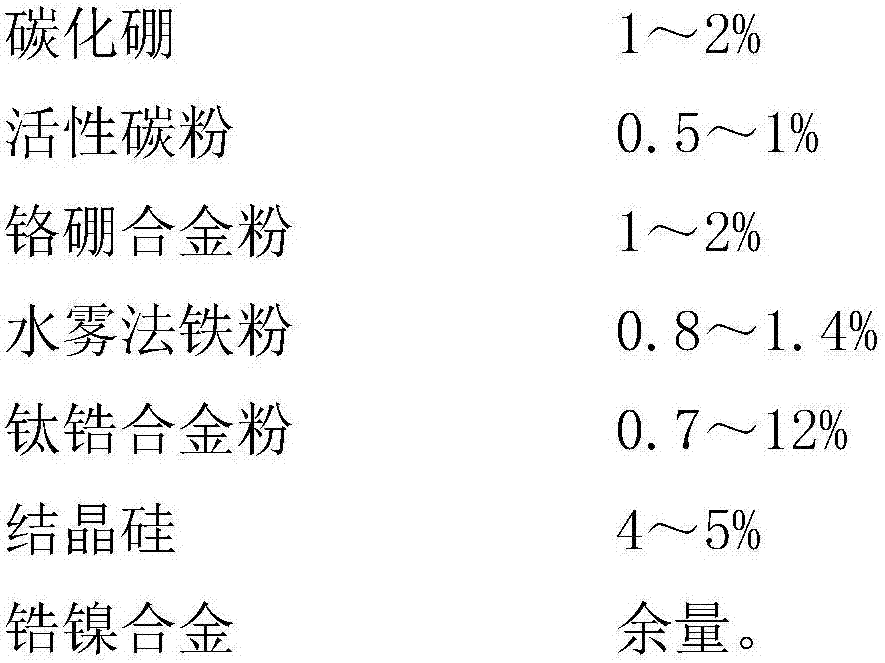

[0016] Nickel-based self-fluxing alloy powder for glass mold remanufacturing, including the following components by mass percentage:

[0017]

[0018] The titanium-zirconium alloy powder includes the following components in mass percentage: Ti is 8%, Fe is 0.20%, Si is 0.60%, and Zr is the balance.

[0019] The zirconium-nickel alloy includes the following components in mass percentage: 74% of Zr and 26% of Ni.

[0020] The chromium-boron alloy powder includes the following components in mass percentage: B is 12%, Al is 2.0%, C is 2%, P is 0.05%, S is 0.01%, and Cr is the balance.

[0021] The invention relates to a welding process of nickel-based self-fluxing alloy powder for glass mold remanufacturing. The nickel-based self-fluxing alloy powder is spray-welded on the surface of a workpiece by an oxygen-acetylene one-step spray-welding process to form a welding layer.

[0022] If the nickel-based self-fluxing alloy powder has moisture absorption, or the storage period exc...

Embodiment 2

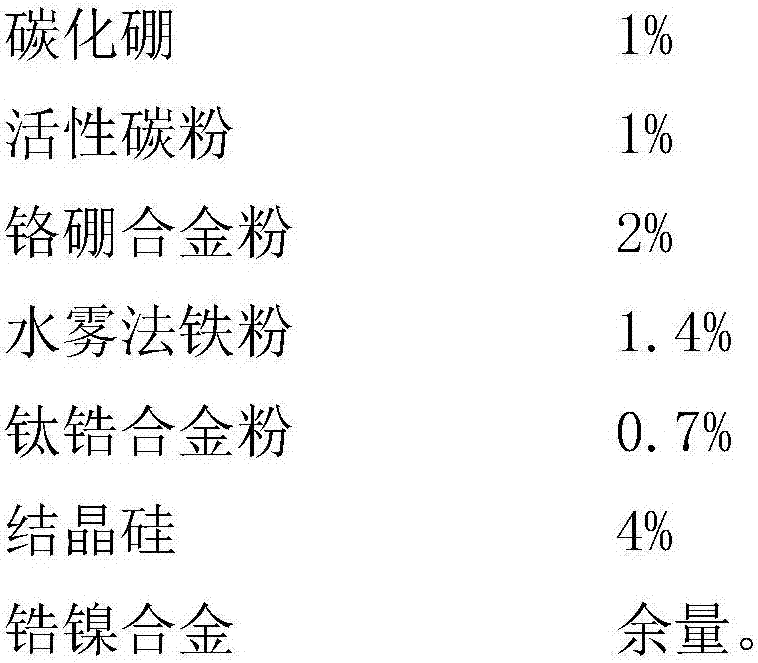

[0025] Nickel-based self-fluxing alloy powder for glass mold remanufacturing, including the following components by mass percentage:

[0026]

[0027] The titanium-zirconium alloy powder includes the following components in mass percentage: Ti is 12%, Fe is 0.1%, Si is 0.2%, and Zr is the balance.

[0028] The zirconium-nickel alloy includes the following components in mass percentage: Zr is 66%, Ni is 32%, and the balance is impurities.

[0029] The chromium-boron alloy powder includes the following components in mass percentage: B is 20%, Al is 0.5%, C is 5%, P is 0.01%, S is 0.05%, and Cr is the balance.

[0030] The invention relates to a welding process of nickel-based self-fluxing alloy powder for glass mold remanufacturing. The nickel-based self-fluxing alloy powder is spray-welded on the surface of a workpiece by an oxygen-acetylene one-step spray-welding process to form a welding layer.

[0031] If the nickel-based self-fluxing alloy powder has moisture absorption...

Embodiment 3

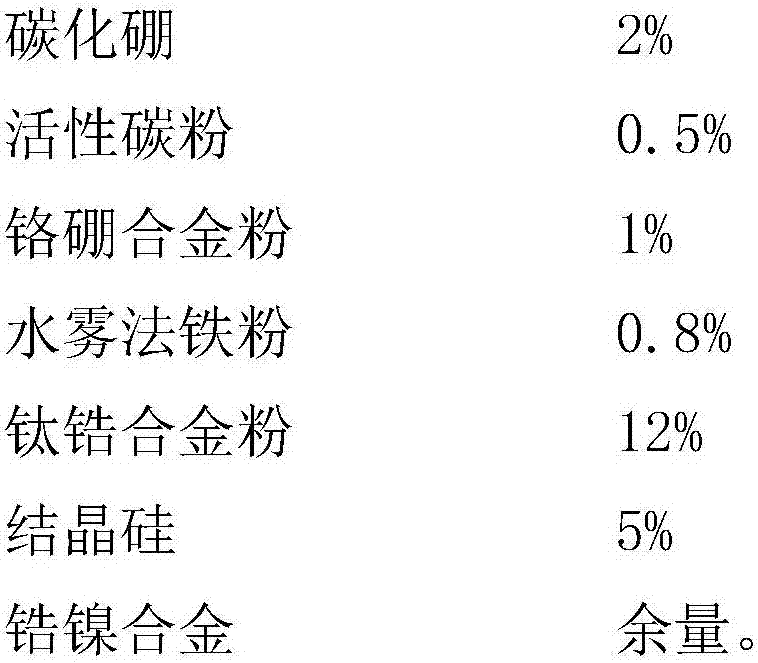

[0034] Nickel-based self-fluxing alloy powder for glass mold remanufacturing, including the following components by mass percentage:

[0035]

[0036] The titanium-zirconium alloy powder includes the following components in mass percentage: Ti is 10%, Fe is 0.15%, Si is 0.4%, and Zr is the balance.

[0037] The zirconium-nickel alloy includes the following components in mass percentage: Zr is 70%, Ni is 28%, and the rest is impurities.

[0038] The chromium-boron alloy powder includes the following components in mass percentage: B is 16%, Al is 1%, C is 4%, P is 0.03%, S is 0.04%, and Cr is the balance.

[0039] The invention relates to a welding process of nickel-based self-fluxing alloy powder for glass mold remanufacturing. The nickel-based self-fluxing alloy powder is sprayed and welded on the surface of a workpiece by an oxygen-acetylene two-step spray welding process to form a welding layer.

[0040] If the nickel-based self-fluxing alloy powder has moisture absorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com